Dual nozzle cap for thermal spray coating

A dual-nozzle, thermal spraying technology, which is applied in coating, melt spraying, metal material coating process, etc., can solve the problems such as the decline of non-crystalline characteristics, achieve the effect of reducing spraying temperature, high strength and elasticity, and preventing bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings, so that those of ordinary skill in the technical field to which the present invention belongs can easily implement the present invention.

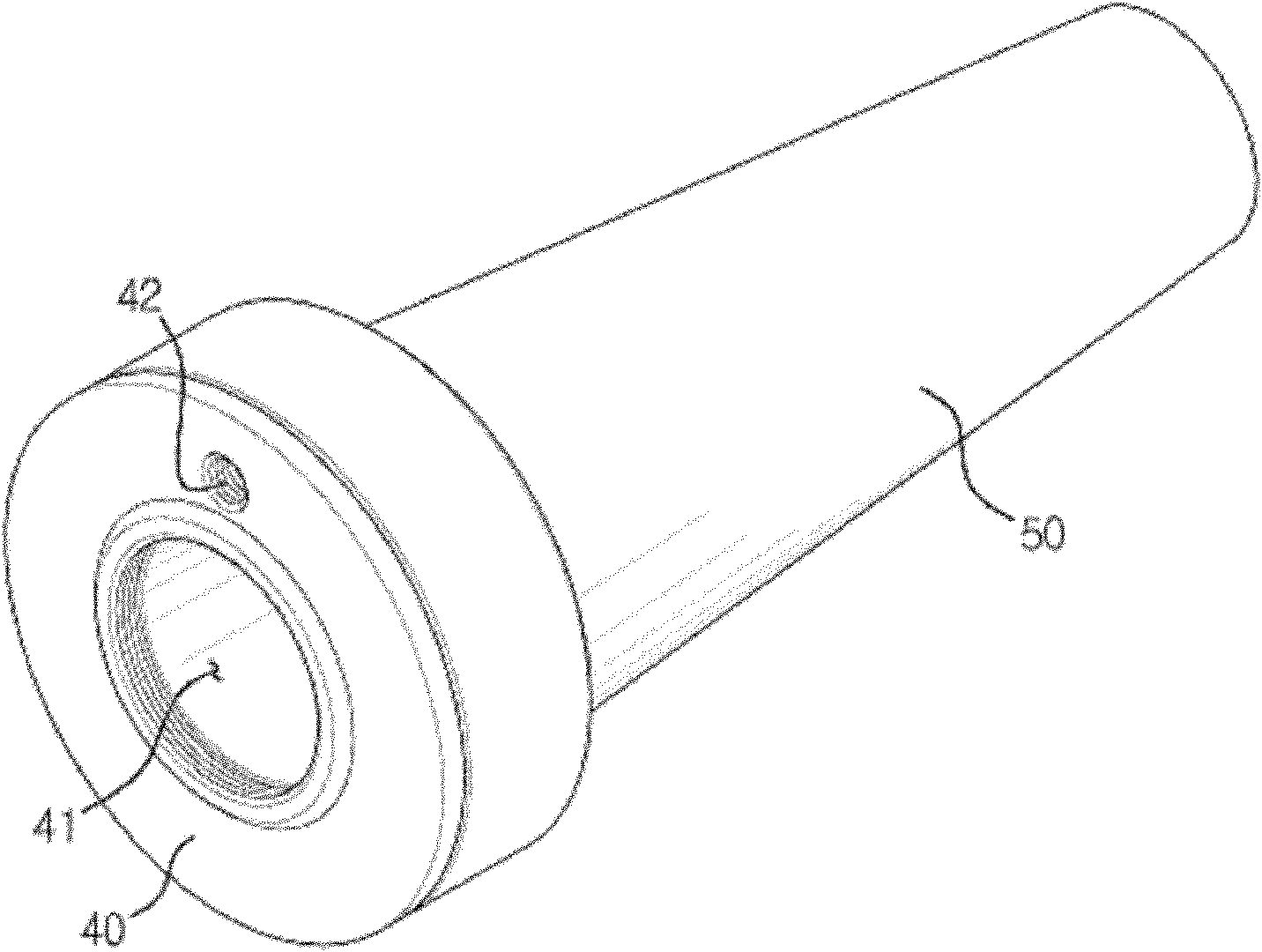

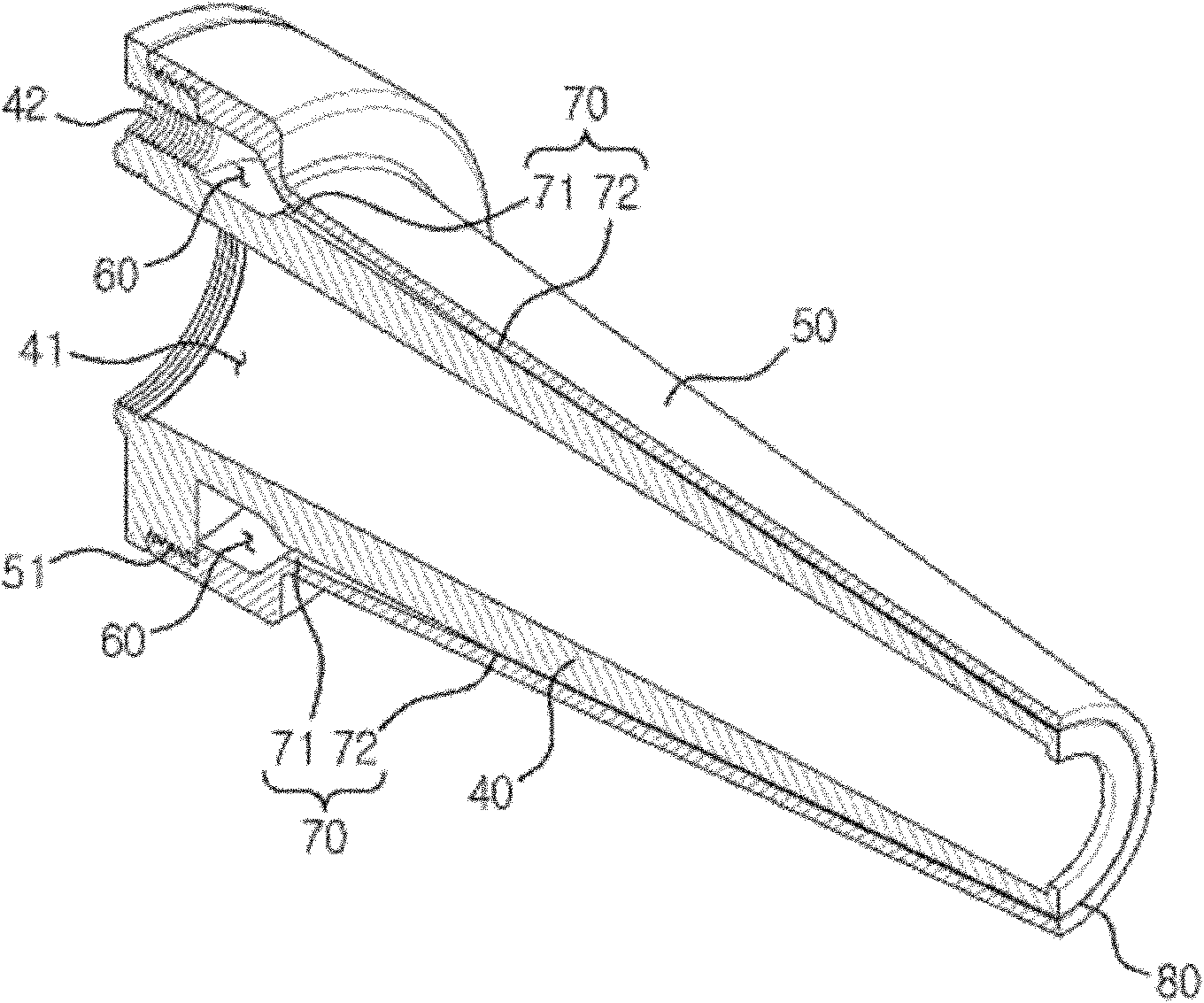

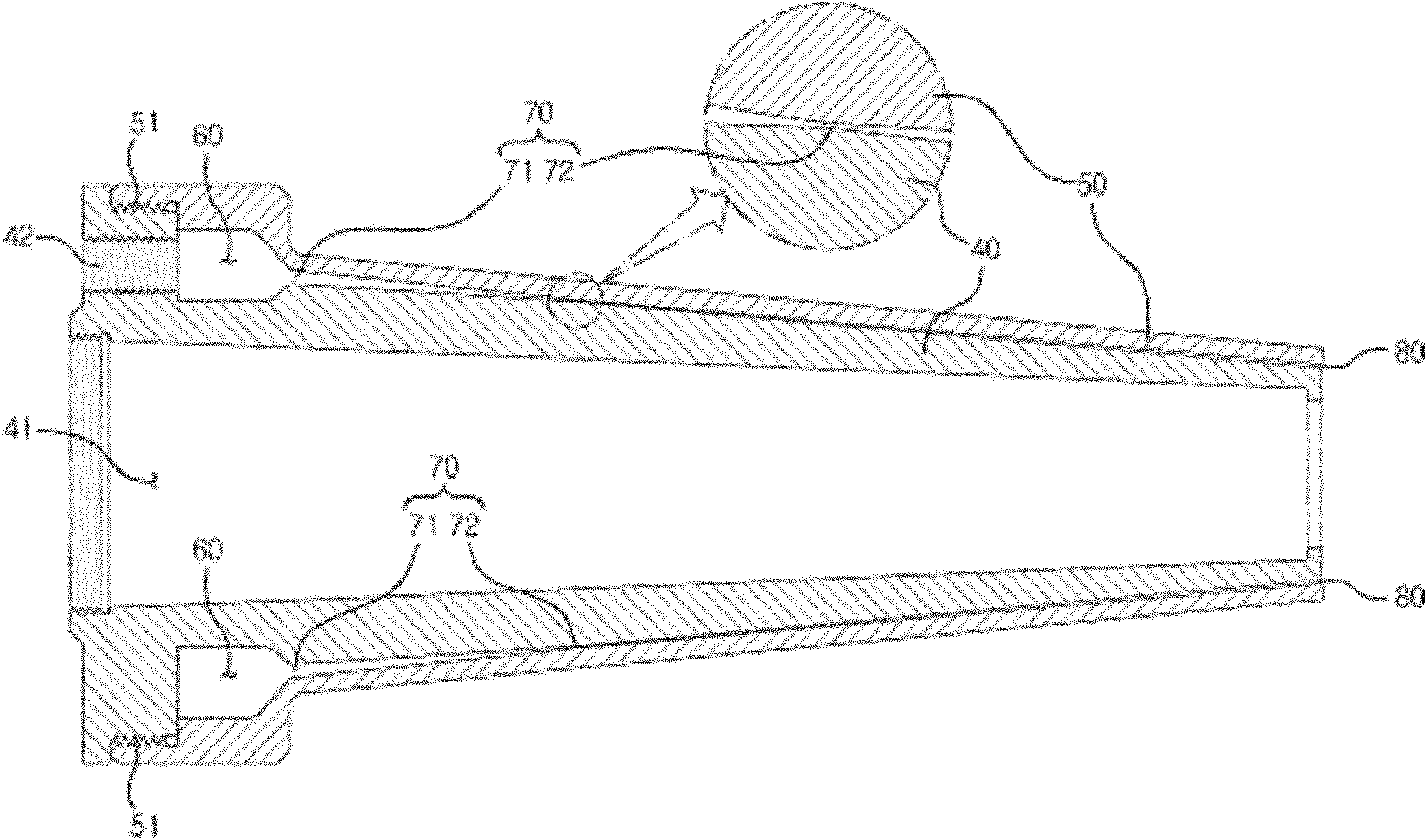

[0023] The overall structure of the embodiment of the dual nozzle cap (cap) for thermal spraying according to the present invention is as follows Figure 1 to Figure 3 shown.

[0024] As shown in the accompanying drawings, the nozzle cap of the present invention installed on the front end of the spray gun 10 is composed of the following parts: an inner nozzle 40, a gun insertion hole 41 for inserting the front end of the above-mentioned spray gun is formed at the center of the inner nozzle; The outer periphery of the inner nozzle 40 and the outer nozzle 50 connected to one side of the inner nozzle 40 , and the annular space between the inner and outer nozzles 40 , 50 for accelerating the injected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com