Environmentally-friendly, high fire-resistant and high seawater-resistant polypropylene

A high-flame-retardant, high-weather-resistant technology, applied in the field of environmentally friendly high-flame-retardant and high-weather-resistant polypropylene, can solve the problems of reduced product surface gloss, product yellowing and discoloration, yellowing and discoloration, etc. The effect of improving the tensile strength and improving the weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 60 parts of copolymerized polypropylene and homopolypropylene, 40 parts of flame retardant melamine polyphosphate, 0.05 part of antioxidant 1010, 0.05 part of antioxidant 618, 0.1 part of ultraviolet absorber phenyl salicylate, light stabilized Add 0.1 part of UV-744, 0.1 part of anti-copper agent MD 1024, and 0.4 part of processing aid polyethylene wax into the high-mixer in sequence, mix thoroughly for 3-5 minutes, put into the twin-screw extruder to mix and melt, and then Prepare standard test pieces to test weather resistance, flame retardancy and mechanical properties.

[0035] Example 1 The copolymerized polypropylene is a copolymerized polypropylene with a melt index of 50 to 150 g / 10min under the test conditions of 230°C and 2.16KG, preferably a copolymerized polypropylene with a melt index of 80 to 120 g / 10min; The polypropylene is a homopolypropylene with a melt index of 10-100 g / 10min under the test conditions of 230°C and 2.16KG, preferably a homopolypropyle...

Embodiment 2

[0040] 70 parts of copolymerized polypropylene or / and homopolypropylene, 15 parts of flame retardant JLS-PNP series, flame retardant Mg(OH) 2 15 parts, 1.0 part of antioxidant 1076, 0.1 part of antioxidant 300, 0.1 part of antioxidant 1034, 0.1 part of ultraviolet absorber UV326, 0.2 part of ultraviolet absorber benzophenone, 0.1 part of light stabilizer UV-744, 0.1 parts of light stabilizer UV-622, 0.05 parts of anti-copper damage agent CL-09-367, 0.15 parts of anti-copper damage agent Mark CDA-1, 0.2 parts of calcium stearate, zinc stearate, and oleic acid amide each Parts are added to the high mixer one by one, fully mixed for 3-5 minutes, put into the twin-screw extruder to mix and melt, and then make standard test pieces to test the weather resistance, flame retardancy and mechanical properties.

[0041] Example 2 The copolymerized polypropylene is a copolymerized polypropylene with a melt index of 50 to 150 g / 10min under the test conditions of 230°C and 2.16KG, preferabl...

Embodiment 3

[0046] 40 parts of copolymerized polypropylene or / and homopolypropylene, 8 parts of flame retardant phosphate ester, 8 parts of flame retardant phosphine oxide, 4 parts of flame retardant red phosphorus, 0.3 parts of antioxidant 1010, 0.2 parts of antioxidant 300 0.15 parts of UV absorber phenyl salicylate, 0.25 parts of UV absorber UV-P, 0.5 parts of light stabilizer UV-744, 0.5 parts of anti-copper poison 1,2-bis(2-hydroxybenzoyl)hydrazine part, 0.5 part of processing aid oleic acid amide, and 0.5 part of processing aid polyethylene wax, which are sequentially added to the high mixer, mixed thoroughly for 3-5 minutes, put into a twin-screw extruder to mix and melt, and then make standard test pieces for further testing. Weather resistance performance, flame retardant performance, mechanical performance test.

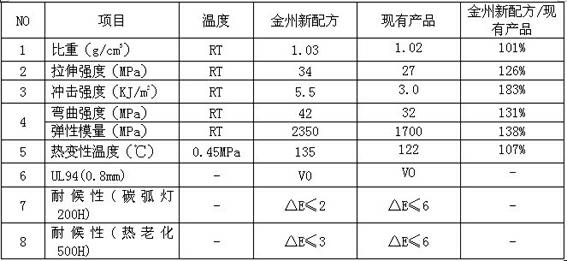

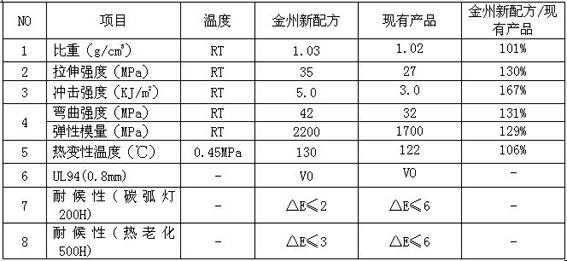

[0047] For the material of the present invention obtained by embodiment 3, by carrying out flame resistance, weather resistance, and initial mechanical properties to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com