Method for preparing efficient copper-doped MoS2 nano-sheet array electrocatalyst

A nanosheet array, electrocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrolysis processes, etc., can solve the problem of limited electrocatalytic water splitting performance, less exposure of active sites, weak surface catalytic activity, etc. To achieve the effect of high-efficiency electrocatalytic decomposition of water for hydrogen production, enriching active sites, and improving the electrocatalytic activity of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Synthesis of MoS 2 nanosheet array

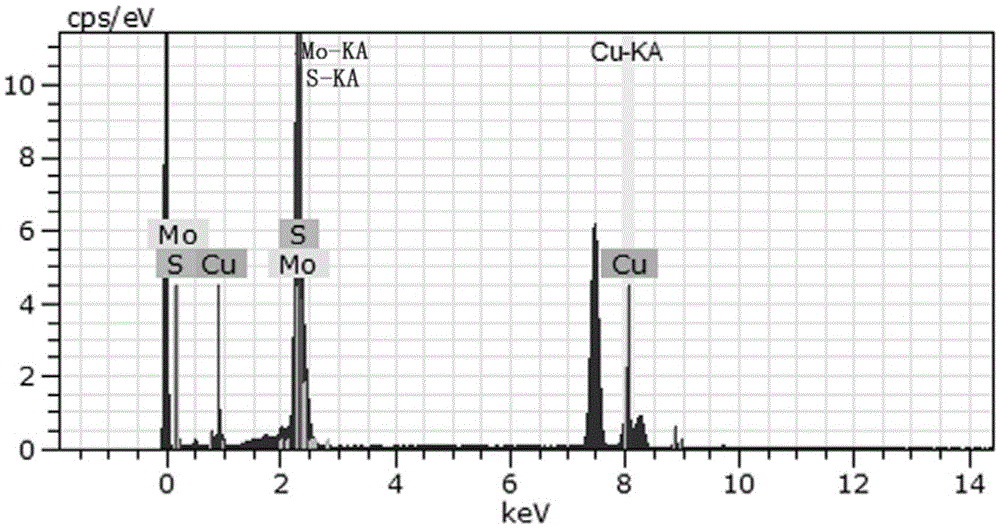

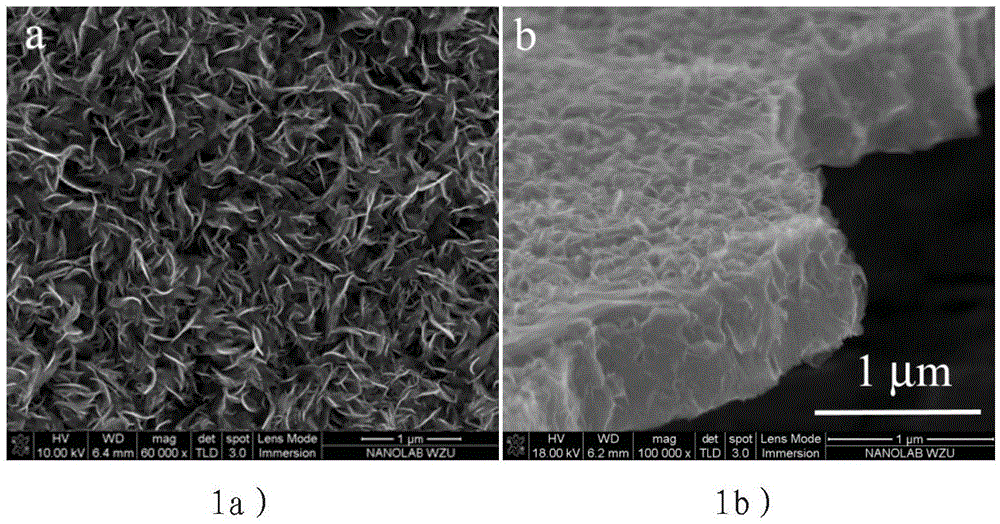

[0037] Weigh 123mg ammonium molybdate tetrahydrate (Mo 7 o 24 .6(NH 4 ).4(H 2 O)), 228mg thiourea (CH 4 N 2 S) After putting into the polytetrafluoroethylene liner (V=60mL) of the autoclave, add 35mL of water, and ultrasonically dissolve in an ultrasonic cleaning instrument for 10min. A piece of 1cm×3cm stainless steel mesh wire was put into this solution, and the autoclave was reacted at a constant temperature of 220° C. for 5 hours in an electric constant temperature blast drying oven. After the reaction was completed, cool to room temperature, and the product was ultrasonicated in ethanol and water for 5 minutes, respectively, and then put into a drying oven to dry for use. figure 1 For the obtained MoS 2 Scanning electron images of nanosheet arrays, 1a) top view and 1b) cross-sectional view. It can be seen from the figure that the material is a nanosheet array structure, and the array height is about 1 μm.

[0038] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com