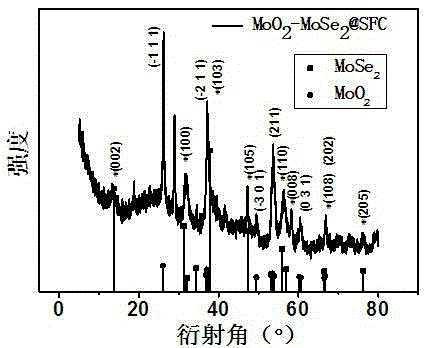

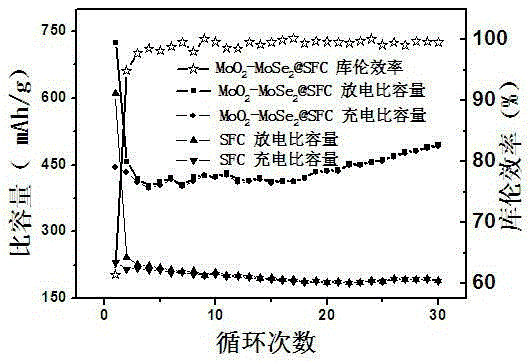

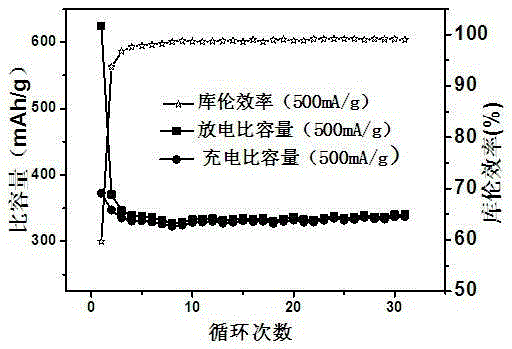

Nano MoO2-MoSe2@SFC lithium ion battery negative electrode material and preparation method therefor

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, nanotechnology, nanotechnology, etc., to achieve good cycle stability and rate performance, improve specific capacity, and excellent electrochemical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] (1) Obtaining sisal fiber carbon: Carbonize the pretreated sisal fiber in a tubular atmosphere furnace, ball mill, and sieve. The heating rate is 3°C / min, the carbonization temperature is 900°C, and the holding time is 0.5 hours. , the ball milling rate is 400r / min, the ball milling time is 12 hours, and the sieve aperture is 0.074mm (200 mesh sieve).

[0023] (2) Configuration solution: Add 1.56g of ammonium molybdate tetrahydrate and 0.14g of selenium dioxide (selenium: molybdenum = 1:1) into 70mL of deionized water. When a colorless and transparent solution is formed, add 0.64g of the step ( 1) After stirring the obtained sisal fiber charcoal for 20 minutes, add 1 mL of analytically pure polyethylene glycol 400, continue stirring for 20 minutes, add 5 mL of hydrazine hydrate with a concentration of 80% by mass, and continue stirring overnight. This suspension is designated as A suspension.

[0024] (3) Hydrothermal reaction: transfer the A suspension into a stainles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com