Preparation method of multilayer molybdenum disulfide material

A technology of molybdenum disulfide and sulfur source, applied in the direction of molybdenum sulfide, etc., can solve the problems of being too expensive and expensive, and achieve the effect of low process conditions and cost, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

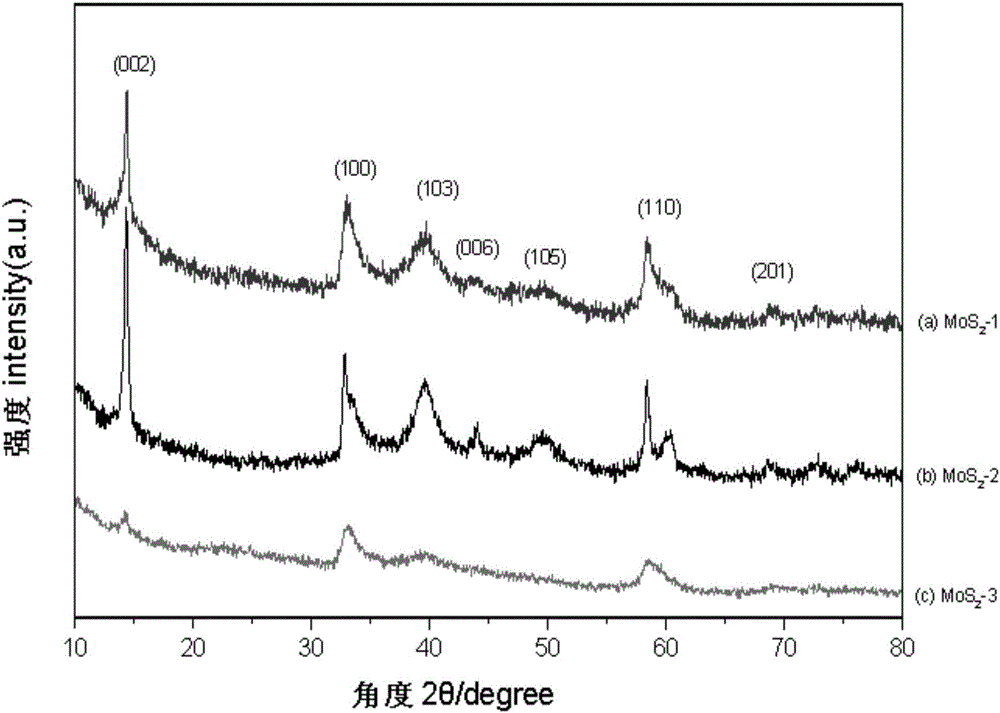

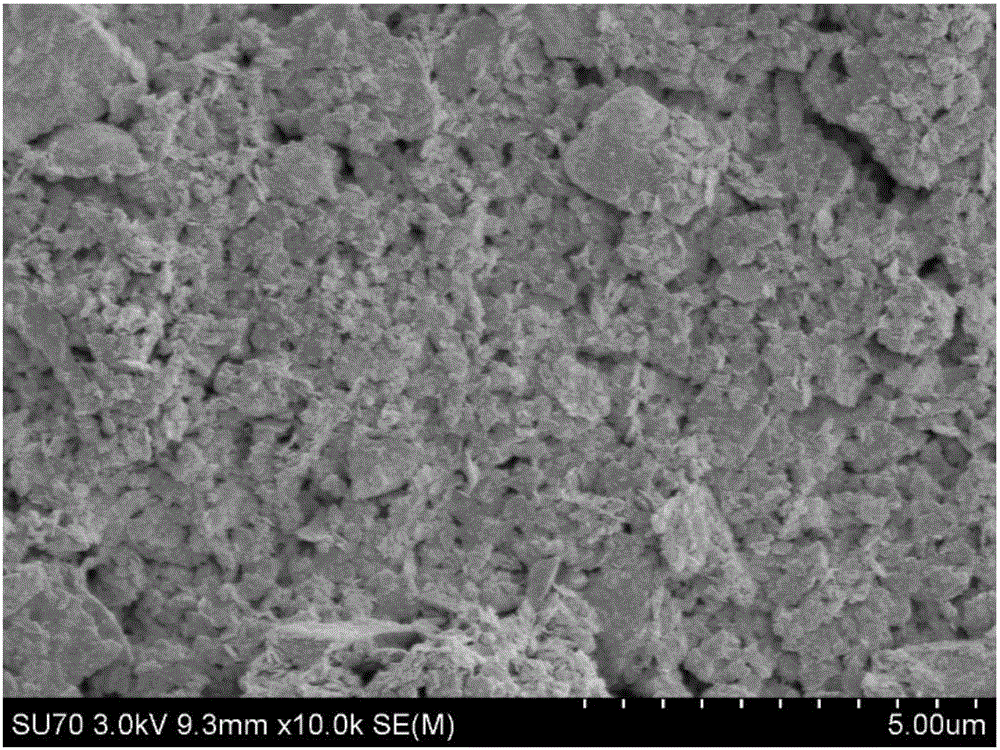

Embodiment 1

[0024] Embodiment 1, a kind of preparation method of multilayer molybdenum disulfide material (the sol-gel synthesis method of multilayer molybdenum disulfide material), carries out following steps successively:

[0025] 1), weighing 0.2g (0.16mmol) ammonium molybdate tetrahydrate as molybdenum source and 0.4g (5.32mmol) thioacetamide as sulfur source; Amide) was poured into 8ml of deionized water, placed on a stirring platform and stirred for 3 hours to completely dissolve the reagent.

[0026] 2) Add 0.05 g (0.13 mmol) of diethyltriaminepentaacetic acid as a chelating agent to the solution obtained in step 1), and stir for 3 hours to obtain a reddish-brown sol.

[0027] 3) Put the sol obtained in step 2) in an oven at 60° C., and obtain a brown gel after 12 hours.

[0028] 4) Continue drying the gel obtained in step 3) at 60° C. for 4 days to completely evaporate the water to obtain a xerogel.

[0029] 5) Put the xerogel obtained in step 4) into a tube furnace for heat tre...

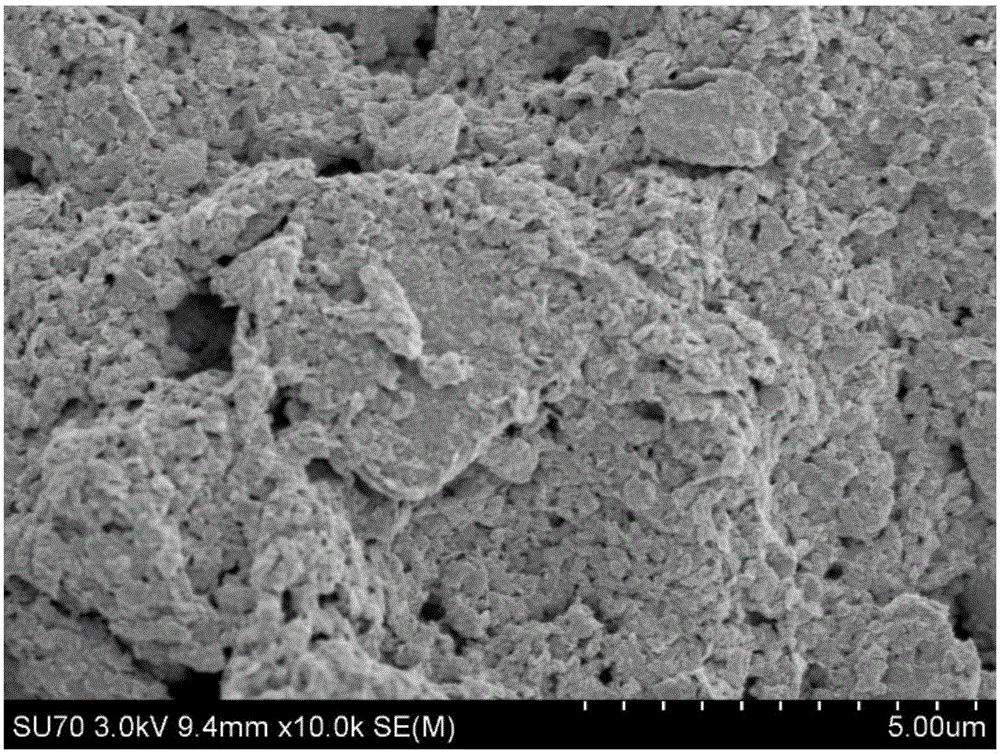

Embodiment 2

[0030] Embodiment 2, change the weight of step 1) thioacetamide in embodiment 1) into 0.6g, and all the other are equal to embodiment 1.

Embodiment 3

[0031] Embodiment 3, change the weight of step 1) thioacetamide in embodiment 1) into 0.8g, all the other are equal to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com