Crystalline silicon solar cell mask manufacturing device

A solar cell and crystalline silicon technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of uncontrollable temperature and the influence of silicon dioxide film compactness, etc., and achieve the effect of dense structure and uniform film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

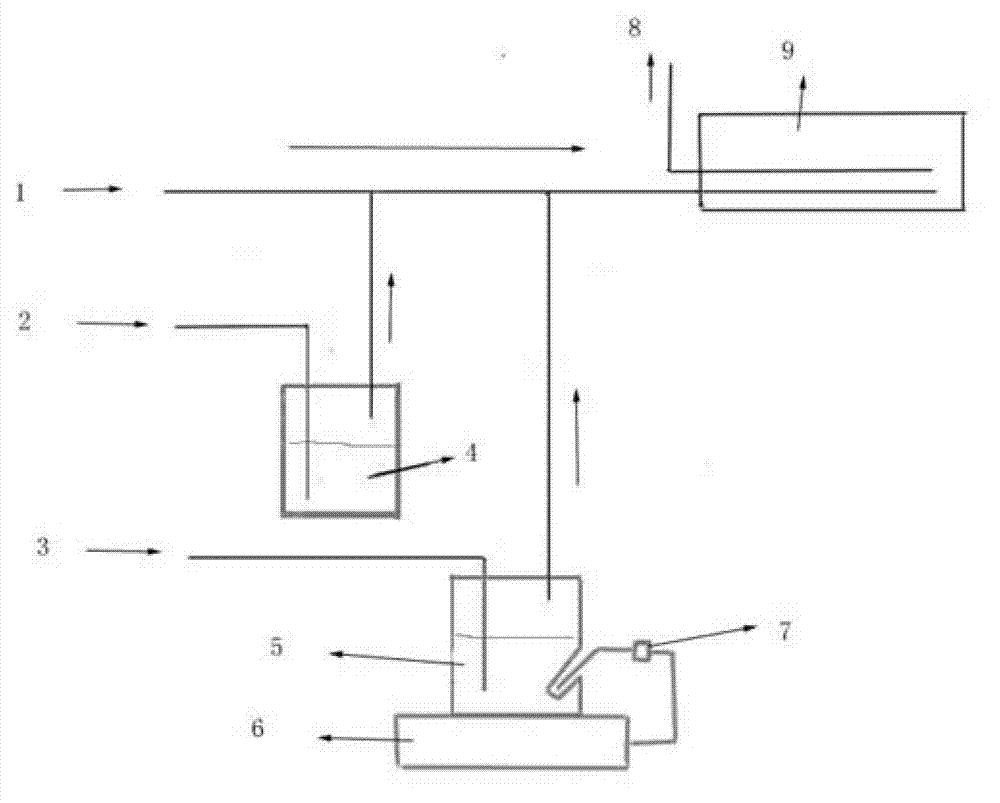

[0017] After the silicon wafer is sent into the reaction chamber 9, the temperature of the reaction chamber 9 is raised to 790 degrees Celsius, and the nitrogen gas introduced from the small flow nitrogen gas inlet 2 passes through the phosphorus source output device 4, and enters the reaction chamber 9 after carrying liquid phosphorus oxychloride with a flow rate of 1000 sccm , deposited on the surface of the silicon wafer to form surface diffusion, the oxygen inlet 3 leads to an oxygen flow rate of 9000 sccm, passes into the deionized water device 5 to form a humid atmosphere, and acts as an oxidation after passing into the reaction chamber 9, so that the silicon containing phosphorus atoms on the surface After being oxidized, a uniform silicon dioxide mask layer is formed, and the reaction waste gas is purged with nitrogen gas from the large-flow nitrogen gas inlet 1 for 10 minutes, and the waste gas exhaust pipe 8 is discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com