Waterborne flame-retardant coating and use method thereof

A flame retardant coating, water-based technology, applied in fire retardant coatings, polycarbonate coatings, coatings, etc., can solve the problems of poor flame retardant performance improvement and poor applicability, and achieve good flame retardant performance and weather resistance. , the effect of uniform film layer

Inactive Publication Date: 2020-07-31

中华制漆(新丰)有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide a water-based flame-retardant coating, which aims to solve the technical problems of the existing water-based coatings, such as the poor effect of improving the flame-retardant performance of PVC wood-plastic composite materials, and poor applicability.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

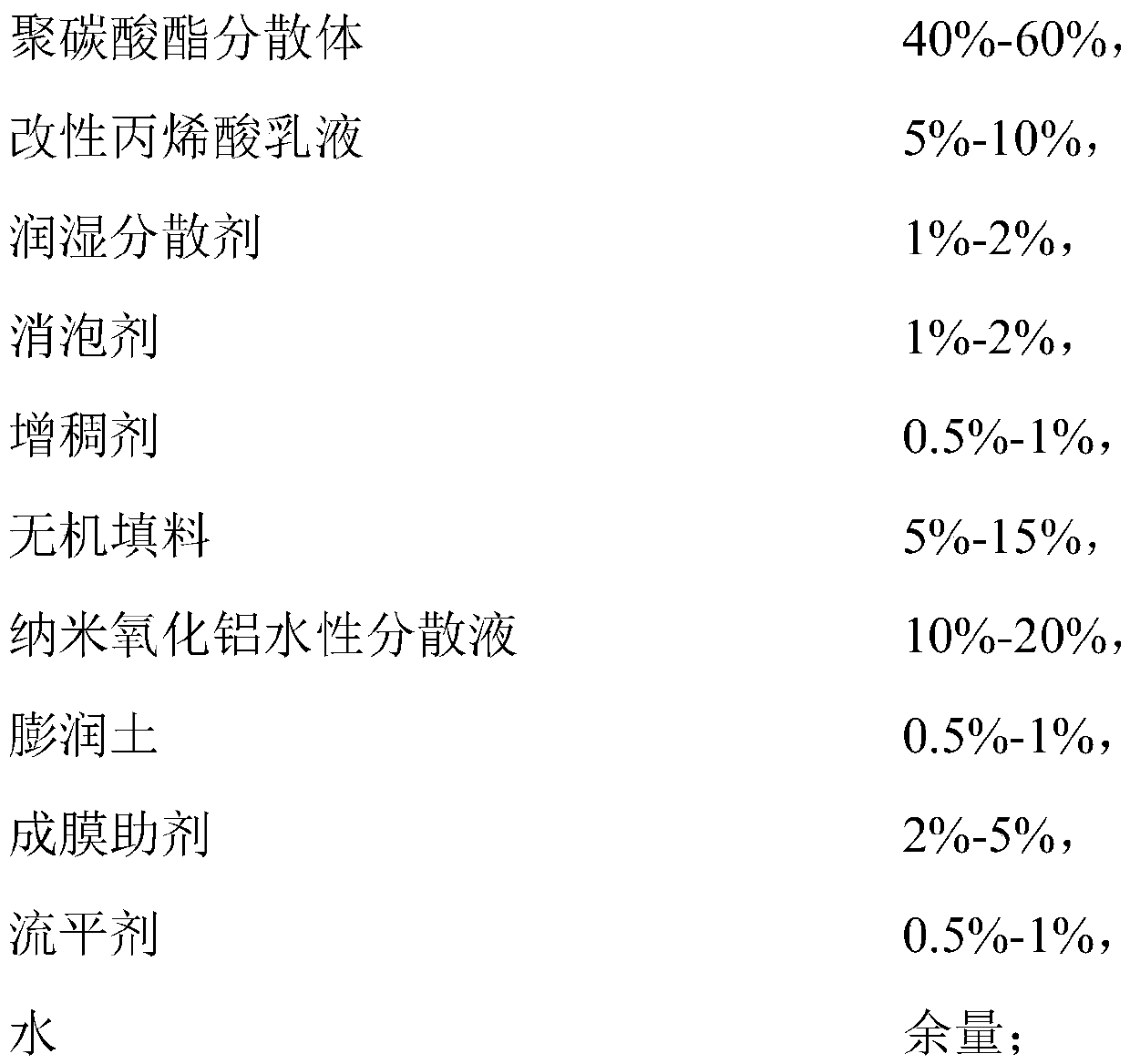

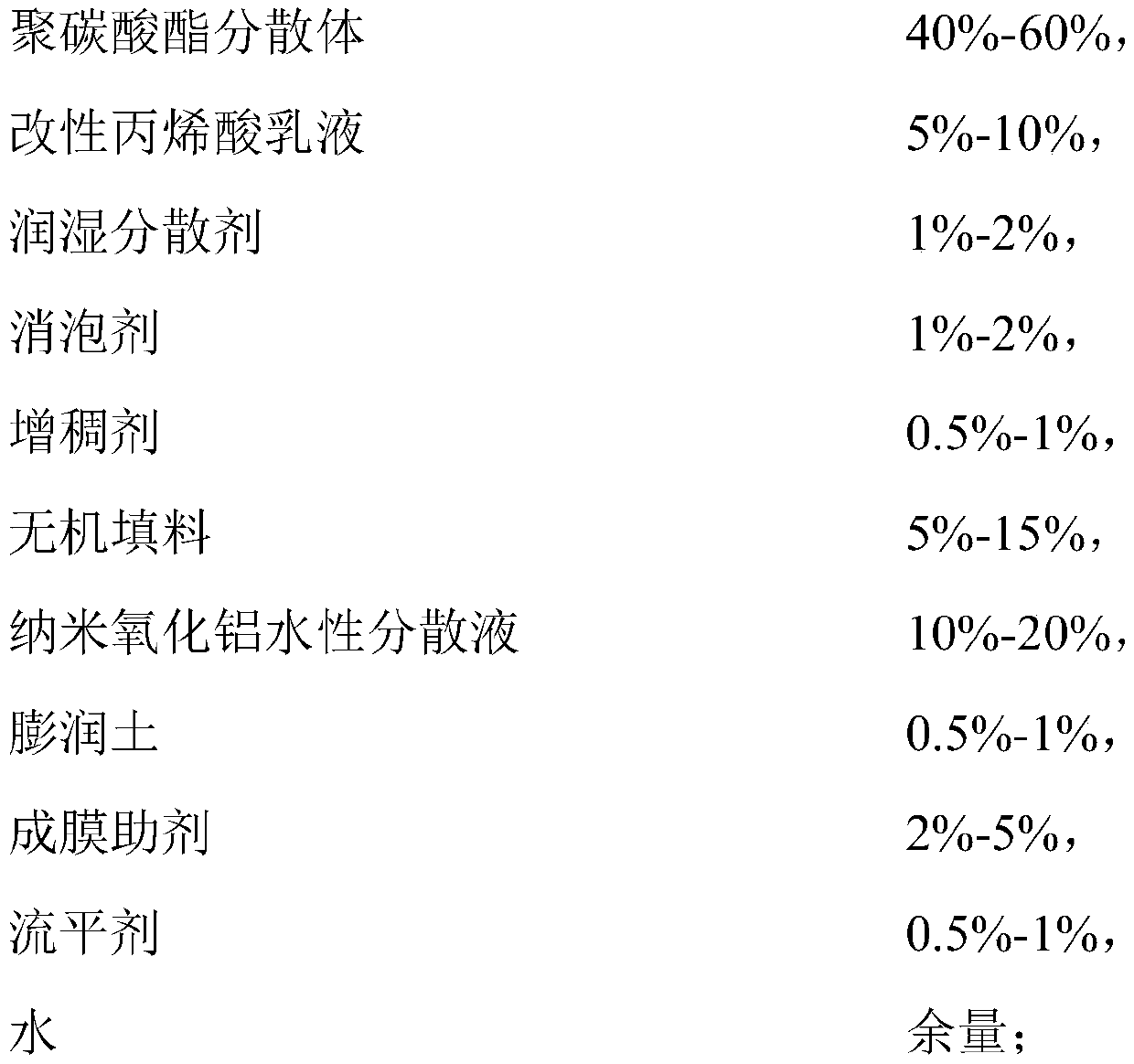

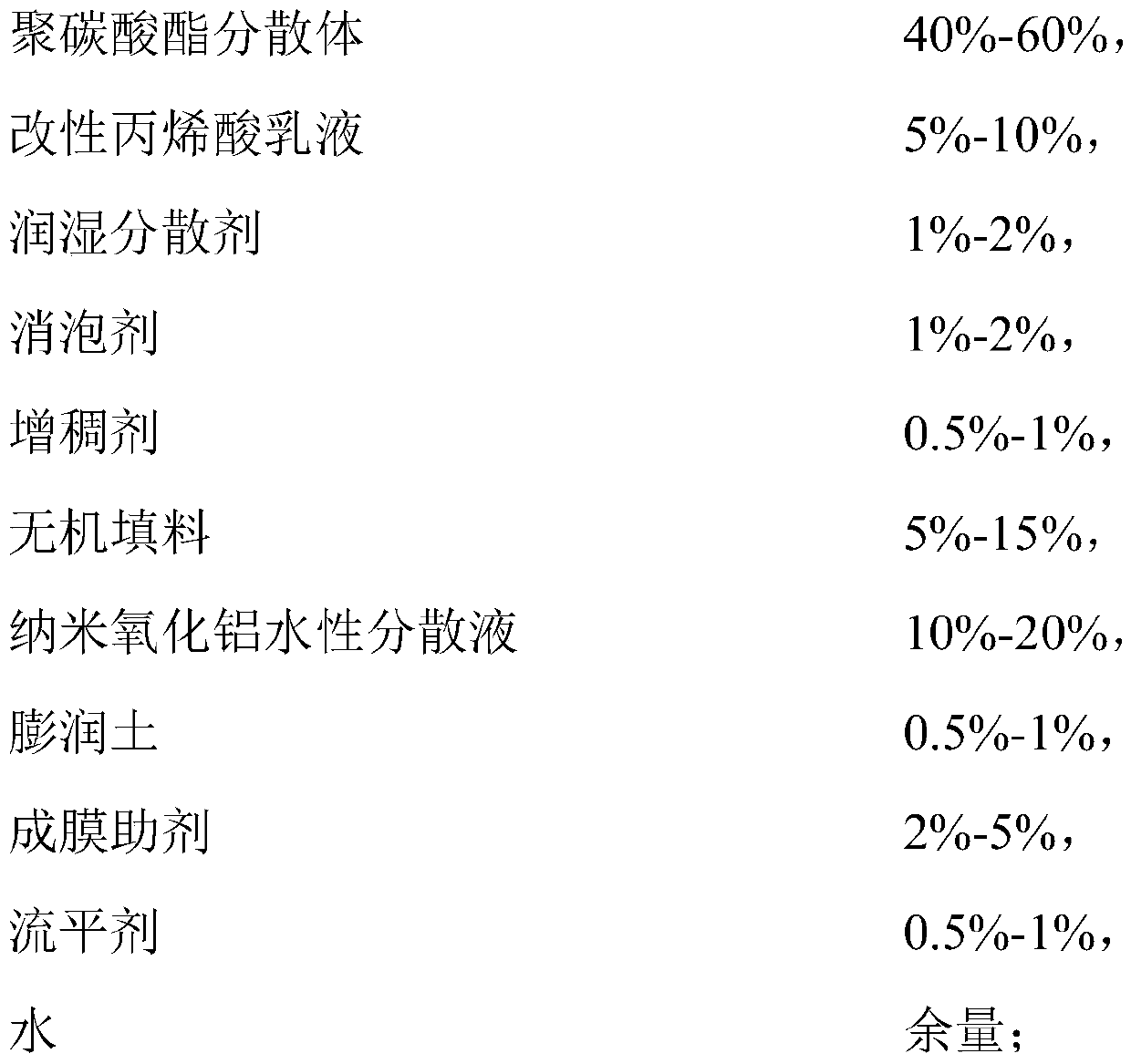

Embodiment 1~3

[0072] Examples 1 to 3 of the present invention respectively provide a water-based flame-retardant coating. The components and ratios of the coatings in each embodiment are shown in Table 1 below:

[0073] Table 1

[0074]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the technical field of coating, in particular to waterborne flame-retardant coating. The coating comprises a component A and a component B. With the total mass of the component A being 100%, the component A comprises 40%-60% of polycarbonate dispersion, 5%-10% of modified acrylic emulsion, 1%-2% of a wetting dispersant, 1%-2% of a defoamer, 0.5%-1% of a thickener, 5%-15% of an inorganic filler, 10%-20% of a dispersant, 0.5%-1% of bentonite, 2%-5% of a coalescing agent, and 0.5%-1% of a leveling agent, with the balance being water. The component B comprises hexamethylene diisocyanate. Through the combined action of the component A and the component B, a coating film formed by the waterborne flame-retardant coating has excellent flame-retardant and heat-insulating properties, has good adhesion on a base material, and can well delay material combustion; and meanwhile, when the flame-retardant coating is coated in a conventional wood product, furniture can obtain good flame retardance, and the product universality is relatively wide.

Description

Technical field [0001] The invention belongs to the technical field of coatings, and particularly relates to a water-based flame-retardant coating and a use method thereof. Background technique [0002] PVC wood-plastic composite material is a green and environmentally friendly composite material that has emerged in recent years at home and abroad. It uses wood processing residues, waste wood and other wood fiber materials and waste PVC as the main raw materials. It is made by extrusion, pressing, injection molding and other molding methods. Into. The main application areas of PVC wood-plastic composite materials are: building materials, outdoor facilities, logistics facilities, transportation facilities, furniture supplies, etc. At present, the annual consumption of various types of wood-plastic panels has exceeded 2 million tons. Because wood fiber materials and PVC are both flammable materials, although flame retardants and inorganic fillers can be added during processing to ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D169/00C09D133/04C09D5/18C09D7/61C09D7/63C09D7/62B05D7/24

CPCC09D169/00C09D5/18C09D7/61C09D7/63C09D7/62C09D5/1662C09D5/1687B05D7/24C08L2201/02C08L2201/08C08K2201/011C08K2003/2227C08K2003/2241C08K2003/3045C08K2003/222C08K2003/265C08L43/04C08K13/06C08K9/04C08K3/346C08K3/22C08K5/29C08K3/34C08K3/24C08K3/30C08K3/26

Inventor 黄伟财周运吉孙旭华

Owner 中华制漆(新丰)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com