Preparation method of glass loaded copper/chromium ion double doped nano titanium dioxide photocatalysis film

A nano-titanium dioxide and photocatalytic film technology, applied in the field of photocatalytic materials, can solve the problems of decreased photocatalytic activity, decreased adsorption performance, low photocatalytic activity, etc., and achieves improved degradation rate, strong adhesion, and high photocatalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

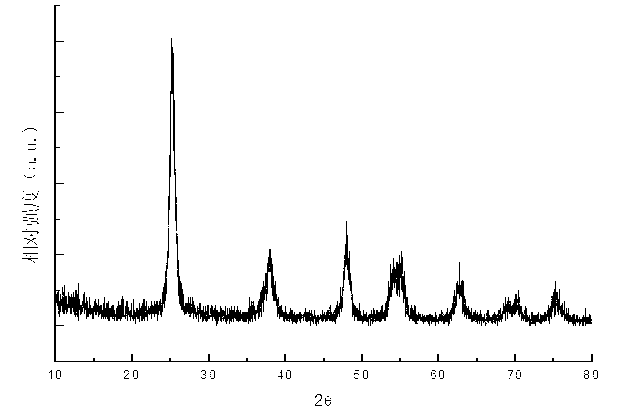

Image

Examples

Embodiment 1

[0025] The glass substrate was first cleaned with tap water, then ultrasonically cleaned with distilled water and absolute ethanol for 5 minutes, and dried in an oven for later use. Dissolve 10g of ethyl silicate (10.7mL, 0.048mol) in 30mL of absolute ethanol (0.51mol), stir well; then add 5mL of 12.2mol / L hydrochloric acid (0.061mol) and 1mL of distilled water (0.056mol), and continue stirring 20 minutes to get stable SiO 2 Sol. Dip the clean glass substrate into the prepared SiO 2 In the sol, the substrate was pulled vertically upward at a pulling speed of 5 cm / min, and then dried at 60°C. Put the dried sample into a muffle furnace and bake it at 500°C for 1 hour to prepare SiO-coated 2 Thin films on glass substrates.

[0026] Stir and mix 8.2mL butyl titanate (also known as tetra-n-butyl titanate), 56.2mL absolute ethanol and 7.0mL glacial acetic acid to form solution A; Cu :M Ti =1.0% and M Cr :M Ti =2.0% Calculate and weigh the required copper nitrate trihydrate a...

Embodiment 2

[0029] The glass substrate was first cleaned with tap water, then ultrasonically cleaned with distilled water and absolute ethanol for 5 minutes, and dried in an oven for later use. Dissolve 10g of ethyl silicate (10.7mL, 0.048mol) in 30mL of absolute ethanol (0.51mol), stir well; then add 5mL of 12.2mol / L hydrochloric acid (0.061mol) and 1mL of distilled water (0.056mol), and continue stirring 20 minutes to get stable SiO 2 Sol. Dip the clean glass substrate into the prepared SiO 2 In the sol, the substrate was pulled vertically upward at a pulling speed of 5 cm / min, and then dried at 60°C. Put the dried sample into a muffle furnace and bake it at 500°C for 1 hour to prepare SiO-coated 2 Thin films on glass substrates.

[0030] Stir and mix 8.2mL butyl titanate, 56.2mL absolute ethanol and 7.0mL glacial acetic acid to form solution A; Cu :M Ti =1.0% and MCr :M Ti =2.0% Calculate and weigh the required copper nitrate trihydrate and chromium nitrate nonahydrate respectiv...

Embodiment 3

[0034] The glass substrate was first cleaned with tap water, then ultrasonically cleaned with distilled water and absolute ethanol for 5 minutes, and dried in an oven for later use. Dissolve 10g of ethyl silicate (10.7mL, 0.048mol) in 30mL of absolute ethanol (0.51mol), stir well; then add 5mL of 12.2mol / L hydrochloric acid (0.061mol) and 1mL of distilled water (0.056mol), and continue stirring 20 minutes to get stable SiO 2 Sol. Dip the clean glass substrate into the prepared SiO 2 In the sol, the substrate was pulled vertically upward at a pulling speed of 5 cm / min, and then dried at 60°C. Put the dried sample into a muffle furnace and bake it at 500°C for 1 hour to prepare SiO-coated 2 Thin films on glass substrates.

[0035] Stir and mix 8.2mL butyl titanate, 56.2mL absolute ethanol and 7.0mL glacial acetic acid to form solution A; Cu :M Ti =1.0% and M Cr :M Ti =2.0% Calculate and weigh the required copper nitrate trihydrate and chromium nitrate nonahydrate respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com