Preparation method of fluorescent-response silica aerogel thin film

A silica and aerogel technology, applied in fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of unsuitability for large-area preparation of thin films, decreased mechanical properties of thin films, and strict molecular structure requirements, saving preparation costs, Simple to use equipment and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

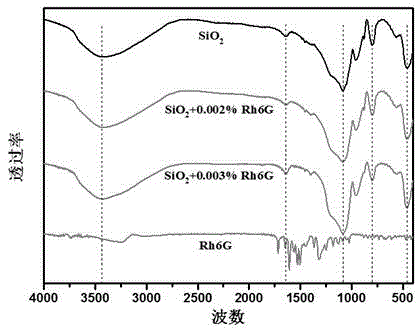

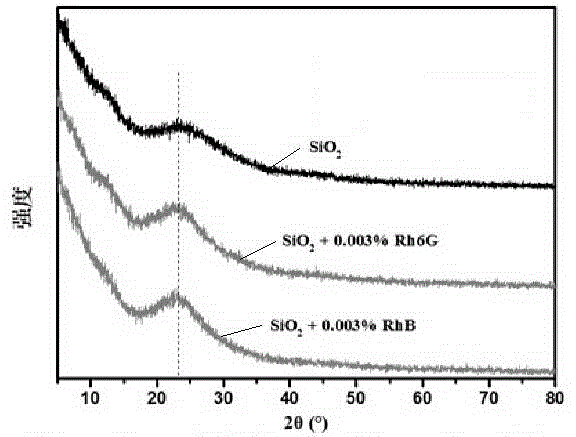

[0038] Add 20 mL tetraethyl orthosilicate dropwise into 21 mL ethanol, mix and stir evenly, add 0.008 mol / L oxalic acid solution 7 mL, stir for 10 h for hydrolysis reaction, then slowly add 0.5 mol / L ammonia solution 0.4 mL, after stirring for another 25 min, add 0.4 mL of 100 mg / L rhodamine 6G ethanol solution, and stir to obtain fluorescent silica sol.

[0039] After immersing the cleaned and dried glass substrate vertically in the fluorescent silica sol for 20 s, the film was coated at a pulling rate of 800 μm / s.

[0040] The obtained wet gel film was dried under normal pressure in an ethanol atmosphere to obtain a silica airgel fluorescent film with a thickness of 112 nm, a sensitive fluorescence response and a fluorescence lifetime of 4.41 ns.

Embodiment 2

[0042] Add 20 mL of tetraethyl orthosilicate dropwise into 21 mL of ethanol, mix and stir evenly, add 7 mL of 0.008 mol / L oxalic acid solution, stir for 11 hours and then slowly add 0.4 mL of 0.5 mol / L ammonia solution, After stirring for 30 min, add 0.8 mL of 100 mg / L rhodamine 6G ethanol solution, and stir to obtain fluorescent silica sol.

[0043] After immersing the cleaned and dried glass substrate vertically in the fluorescent silica sol for 30 s, the film was coated at a pulling rate of 900 μm / s.

[0044] The obtained wet gel film was dried under normal pressure in an ethanol atmosphere to obtain a silica airgel fluorescent film with a thickness of 116 nm, a sensitive fluorescence response and a fluorescence lifetime of 4.81 ns.

Embodiment 3

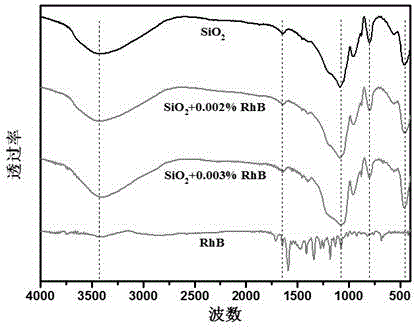

[0046] Add 22 mL of tetraethyl orthosilicate to 23 mL of ethanol dropwise, mix and stir evenly, add 7 ml of 0.008 mol / L oxalic acid solution, stir for 12 h for hydrolysis, then slowly add 0.4 mL of 0.5 mol / L ammonia solution dropwise , after stirring for 20 min, add 0.8 mL of 100 mg / L rhodamine B ethanol solution, and stir to obtain fluorescent silica sol.

[0047] After immersing the cleaned and dried glass substrate vertically in the fluorescent silica sol for 50 s, the film was coated at a pulling rate of 1000 μm / s.

[0048] The obtained wet gel film was dried under normal pressure in an ethanol atmosphere to obtain a silica airgel fluorescent film with a thickness of 115 nm, a sensitive fluorescence response and a fluorescence lifetime of 4.88 ns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com