Halogen-doped ZnMgO film and preparation method thereof

A thin film and halogen technology, applied in the field of halogen-doped ZnMgO thin film and its preparation, can solve the problems of low repeatability, high level of preparation process, high cost, etc., and achieve the effects of simplified preparation process, wide application prospect and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a halogen-doped ZnMgO thin film, comprising the steps of:

[0033] 1) Dip the Si sheet or quartz glass sheet into acetone, absolute ethanol, and deionized water respectively, then use an ultrasonic cleaning machine to sonicate for 15 minutes and dry it with an infrared lamp;

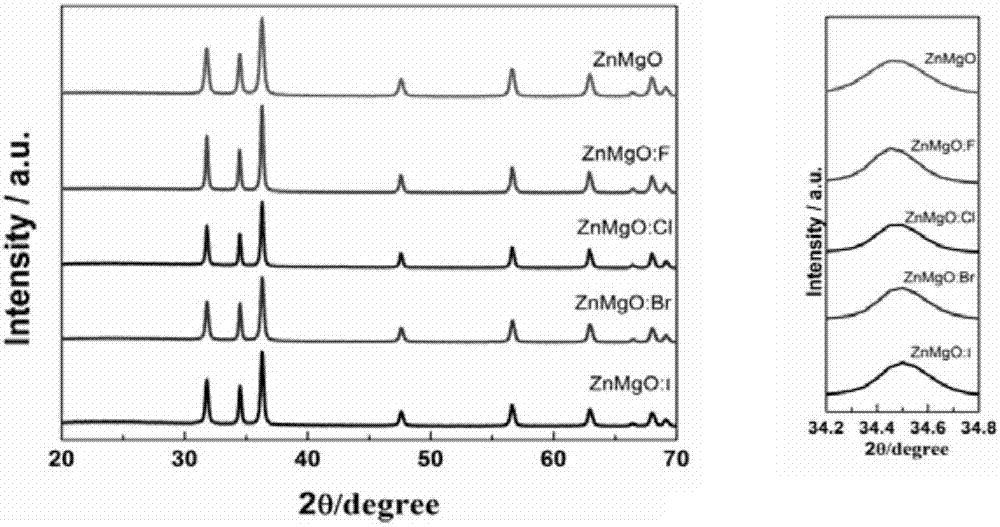

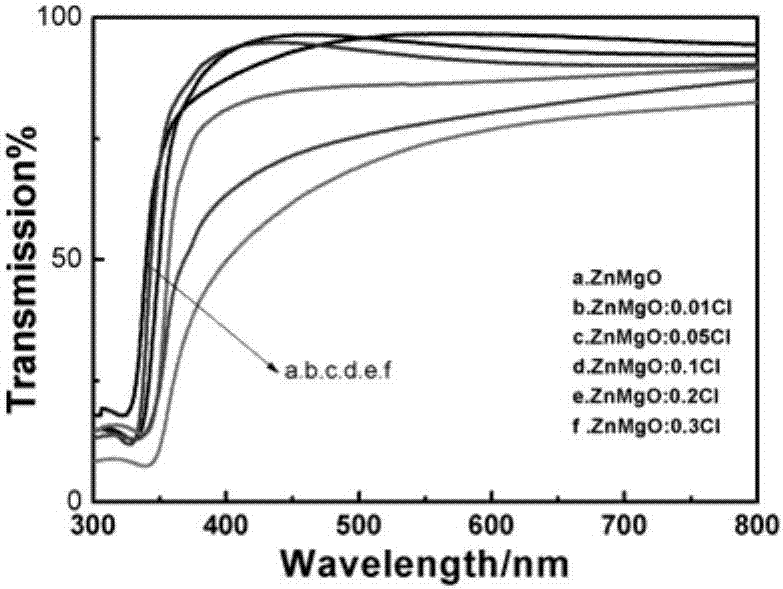

[0034] 2) 2.1064g of zinc acetate dihydrate and 0.1083g of magnesium acetate tetrahydrate solid were dissolved in 50ml of ethylene glycol methyl ether solution, and then 0.98mL of ethanolamine (MEA) was added to make Zn in the solution 2+ , Mg 2+ Concentration [Zn 2+ +Mg 2+ ]: The molar concentration ratio of ethanolamine (MEA) is ≈1, and then placed on a constant temperature magnetic stirrer for full stirring. The temperature is set at 70°C, and the holding time is 1 hour to obtain Zn 0.95 Mg 0.05 O sol, then add 0.01mol of NH 4 X (X represents a halogen, such as one of F, Cl, Br, and I), and continued to stir for 2h to realize the doping of ZnMgO by halogen. After f...

Embodiment 2

[0038] Embodiment 2 (for comparative example):

[0039] A method for preparing a halogen-doped ZnMgO thin film, comprising the steps of:

[0040] 1) Dip the Si sheet or quartz glass sheet into acetone, absolute ethanol, and deionized water respectively, then use an ultrasonic cleaning machine to sonicate for 15 minutes and dry it with an infrared lamp;

[0041] 2) 2.1064g of zinc acetate dihydrate and 0.1083g of magnesium acetate tetrahydrate solid were dissolved in 50ml of ethylene glycol methyl ether solution, and then 0.98mL of ethanolamine (MEA) was added to make Zn in the solution 2+ : The molar concentration ratio of MEA is ≈1, and then placed on a constant temperature magnetic stirrer for full stirring. The temperature is set at 70°C and the holding time is 3h to obtain Zn 0.95 Mg 0.05 The sol of O does not use halogen doping. After fully stirring, cool to room temperature and filter through filter paper to obtain a transparent sol with a cation concentration of 0.2...

Embodiment 3

[0046] A method for preparing a halogen-doped ZnMgO thin film, comprising the steps of:

[0047] 1) Dip the Si sheet or quartz glass sheet into acetone, absolute ethanol, and deionized water respectively, then use an ultrasonic cleaning machine to sonicate for 15 minutes and dry it with an infrared lamp;

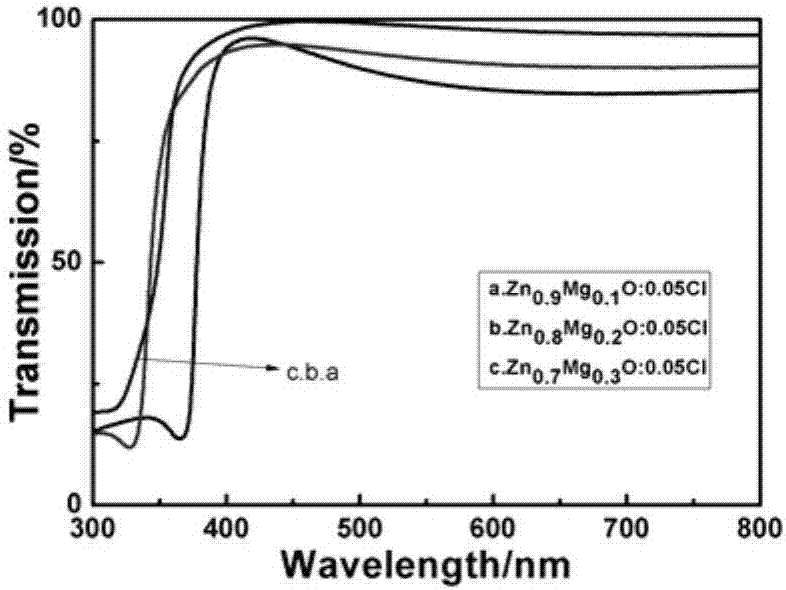

[0048] 2) 1.9956, 1.7738, 1.5521g of zinc acetate dihydrate and 0.2166, 0.4332, 0.6498g of magnesium acetate tetrahydrate solid were dissolved in 50ml of ethylene glycol methyl ether solution, and then 0.98mL of ethanolamine (MEA) was added, so that Zn in solution 2+ , Mg 2+ Concentration [Zn 2+ +Mg 2+ ]: MEA molar concentration ratio ≈ 1, and then placed on a constant temperature magnetic stirrer for full stirring. Configured as Zn respectively 0.9 Mg 0.1 O, Zn 0.8 Mg 0.2 O, Zn 0.7 Mg 0.3 O three kinds of sols, in which the temperature was set at 70 ° C, the holding time was 1 hour, and then 0.05 mol of NH was added 4 Cl, and continue stirring for 2h to realize C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com