Preparation method of metalloid graphene negative electrode material and battery

A metal graphite, negative electrode material technology, applied in negative electrodes, electrode manufacturing, battery electrodes, etc., can solve the problems of low conductivity of nanocomposite materials, and achieve the effect of reducing rearrangement, stable circulation, and buffering volume changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

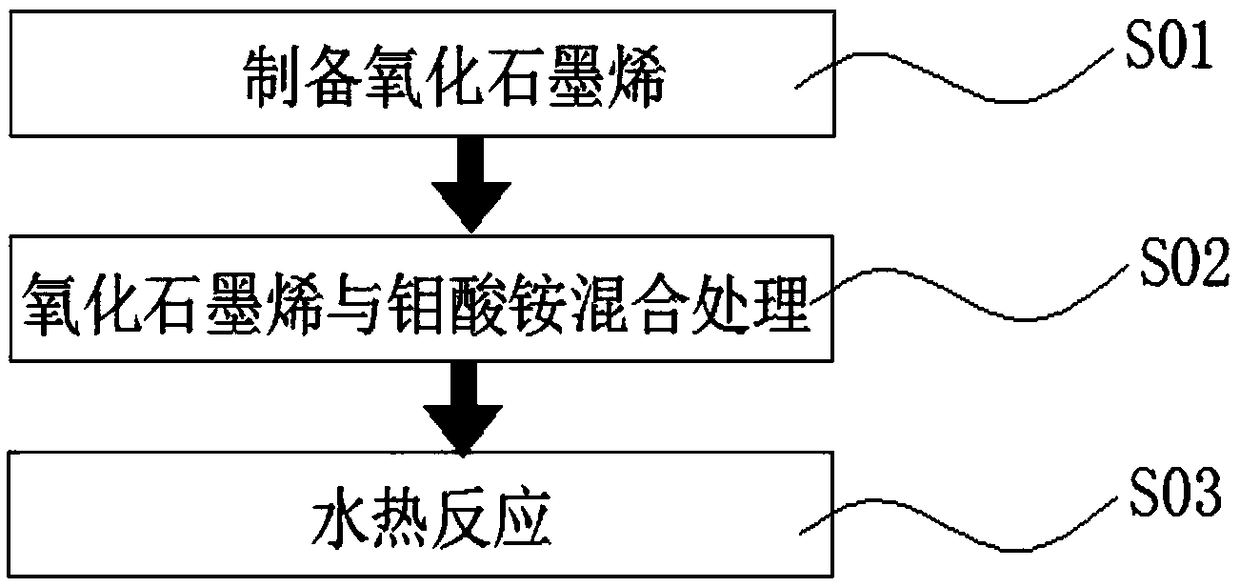

[0042] Preparation of graphene oxide: the H 2 SO 4 and H 3 PO 4 Mix at a volume ratio of 9:1 to obtain concentrated H 2 SO 4 / H 3 PO 4 Mixed solution; 1.5g graphite powder and 9g potassium permanganate (KMnO 4 ) were evenly mixed; then 180mL concentrated H 2 SO 4 / H 3 PO 4 Add graphite powder and KMnO to the mixed solution 4 Then, the mixture was heated to 50°C and kept stirring for 20h; then the reaction solution was poured into 200mL of ice water, and 30% hydrogen peroxide was added dropwise to the solution until the color of the solution became golden yellow; Then the mixture was centrifuged at 4000 rpm for 30 min, and the resulting mixture was washed with deionized water and extracted in ethanol; finally, the extract was freeze-dried for 24 h to obtain graphene oxide (GO).

[0043] Graphene oxide and ammonium molybdate mixed treatment: first 60mg ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) and 1.5g thiourea (CN 2 h 4 S) carry out homogeneous mixing; ...

Embodiment 2

[0051] Preparation of graphene oxide: first, the H 2 SO 4 and H 3 PO 4 Mix at a volume ratio of 9:1 to obtain concentrated H 2 SO 4 / H 3 PO 4 Mixed solution; 2g graphite powder and 10g potassium permanganate (KMnO 4 ) were evenly mixed; then 180mL concentrated H 2 SO 4 / H 3 PO 4 Add graphite powder and KMnO to the mixed solution 4Then, the mixture was heated to 55°C and kept stirring for 22h; then the reaction solution was poured into 200mL of ice water, and then 30% hydrogen peroxide was added dropwise to the solution until the color of the solution became golden yellow; Then the mixture was centrifuged at 4000 rpm for 60 min, and the resulting mixture was washed with deionized water and extracted in ethanol; finally, the extract was freeze-dried for 24 h to obtain graphene oxide (GO).

[0052] Graphene oxide and ammonium molybdate mixed treatment: first 60mg ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) and 2g thiourea (CN 2 h 4 S) carry out homogeneous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com