Preparation method of block NiS2 and application of block NiS2 to sodium-ion battery

A block and centrifugal separation technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., to achieve the effect of reducing electrode potential, increasing contact area, and high capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

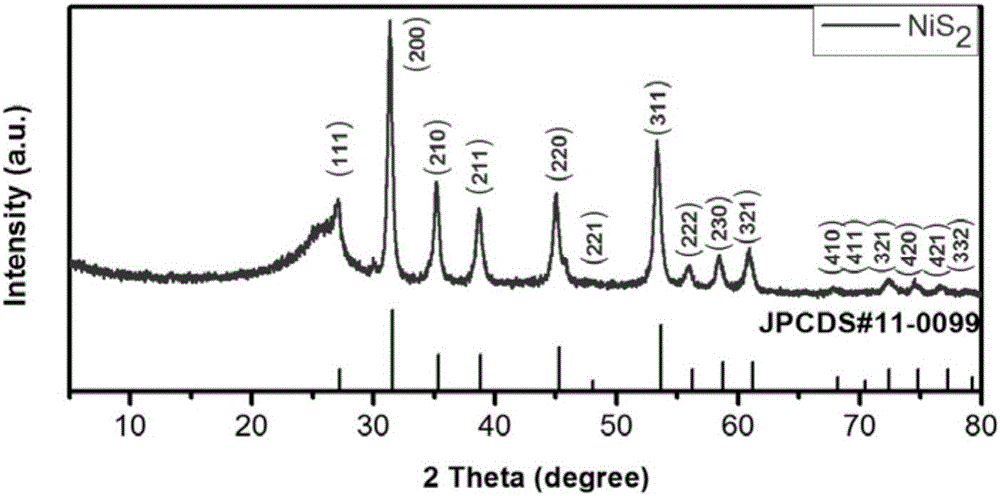

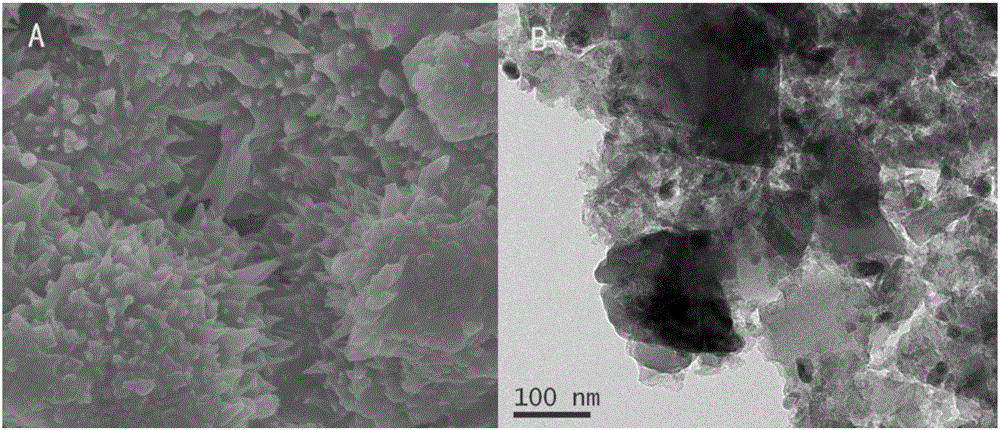

[0031] ①With 5mmol of commercialized Ni(NO 3 ) 2 4H 2 Dissolve O in 30mL of methanol, stir for an appropriate amount of time until it is completely dissolved; ②Dissolve 20mmol of 2-methylimidazole in 30mL of methanol, stir until it is completely dissolved. Pour ② into ① and let it stand at room temperature for 24 hours. Then, after centrifuging and washing with methanol three times, dry it in a drying oven at 50°C for 12 hours to obtain a precursor containing Ni, then take an appropriate amount of precursor and sulfur powder and grind them in an agate mortar with a mass ratio of 2:1, and then vacuum seal The tube was heat-treated in a tube furnace at 600°C to obtain the product. SEM( figure 2 A) and TEM ( figure 2 B) The results show that the synthesized NiS 2 It is a bulky morphology composed of nanoparticles, and XRD ( figure 1 ) results show that its purity is high, its crystallinity is good, and it is a single pure phase.

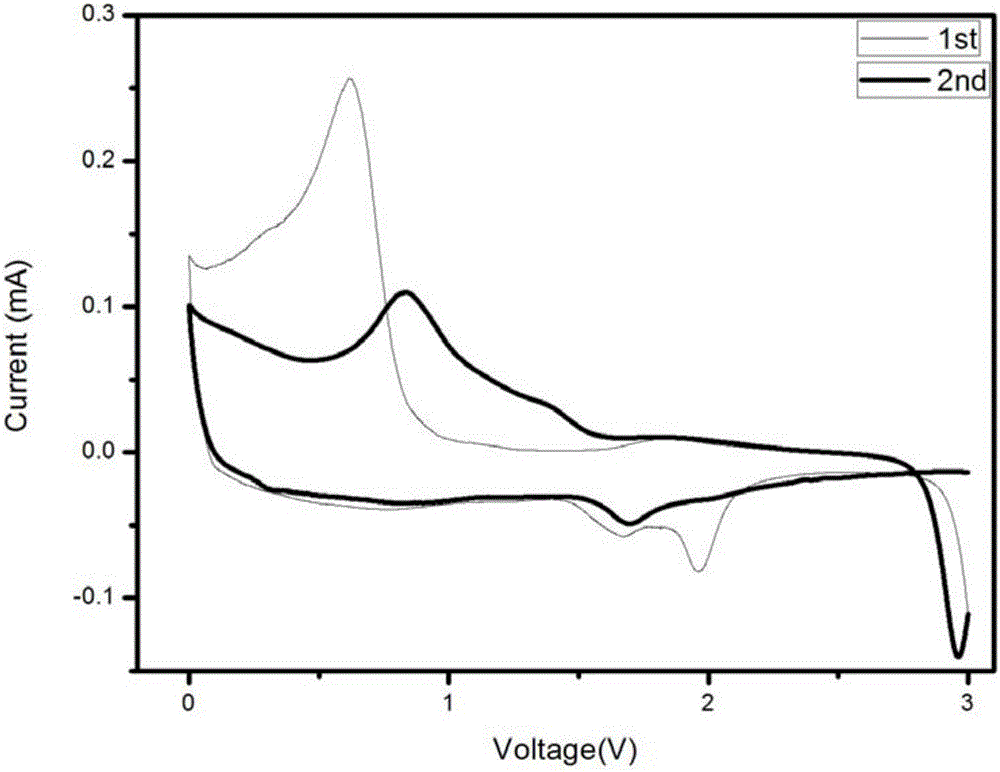

[0032] The prepared NiS 2 The active m...

Embodiment 2

[0034] ①With 5mmol of commercialized Ni(NO 3 ) 2 4H 2 Dissolve O in 30mL of methanol, stir for an appropriate amount of time until it is completely dissolved; ②Dissolve 15mmol of 2-methylimidazole in 30mL of methanol, stir until it is completely dissolved. Pour ② into ① and let it stand at room temperature for 2 hours. Then, after centrifuging and washing with methanol three times, dry it in a drying oven at 50°C for 12 hours to obtain a precursor containing Ni, then take an appropriate amount of precursor and sulfur powder and grind them in an agate mortar with a mass ratio of 4:1, and then vacuum seal The tube was heat-treated in a tube furnace at 400°C to obtain the product. Detected by SEM and TEM, the results showed that the synthesized NiS 2It is a block shape composed of nanoparticles, and the XRD results show that its purity is high, and it is a single NiS 2 crystal phase.

[0035] The method for preparing the sodium ion battery is as in Example 1, and the prepar...

Embodiment 3

[0037] ①With 5mmol of commercialized Ni(NO 3 ) 2 4H 2 Dissolve O in 30mL of methanol, stir for an appropriate amount of time until it is completely dissolved; ②Dissolve 25mmol of 2-methylimidazole in 30mL of methanol, stir until it is completely dissolved. Pour ② into ① and let it stand at room temperature for 18 hours. Then, after centrifuging and washing with methanol three times, dry it in a drying oven at 50°C for 12 hours to obtain a precursor containing Ni, then take an appropriate amount of precursor and sulfur powder and grind them in an agate mortar with a mass ratio of 1:1, and then vacuum seal The tube was heat-treated in a tube furnace at 800°C to obtain the product. Detected by SEM and TEM, the results showed that the synthesized NiS 2 It is a block shape composed of nanoparticles, and the XRD results show that its purity is high, and it is a single NiS 2 crystal phase.

[0038] The method for preparing the sodium ion battery is as in Example 1, and the prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com