Agricultural waste fuel cell

An agricultural waste and fuel cell technology, applied in the direction of biochemical fuel cells, etc., can solve the problems of low degradation efficiency of agricultural waste, expensive electrode materials and catalysts, and low output power density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0052] Such as figure 1 As shown, an agricultural waste fuel cell includes an anode side constituent material, an anode circulation system, a proton exchange membrane 6, a cathode side constituent material, and a cathode circulation system, and the proton exchange membrane 6 is placed in the cathode circulation system and the anode circulation system Among them, the constituent substances on the anode side are stored in the anode circulation system, the constituent substances on the cathode side are stored in the cathode circulation system, the substances on both sides are separated by the proton exchange membrane 6, and the constituent substances on the anode side transfer the carried electrons to the In the external circuit, protons pass through the proton exchange membrane 6 and are pumped into the cathode side through the cathode circulation system to combine with electrons in the external circuit to form water. The anode circulation system includes an anode reaction tank ...

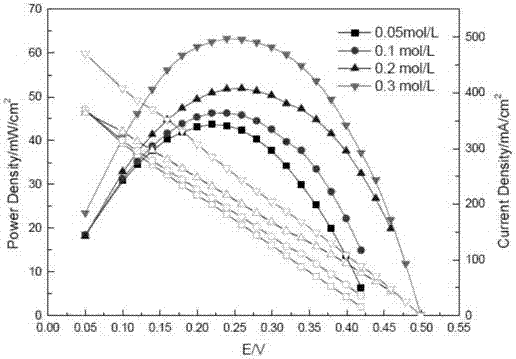

Embodiment 1

[0056] 1. Preparation of anolyte (POM-A)

[0057]Take a certain amount of phosphomolybdic acid H 3 [PMo 12 o 40 ], respectively prepared into 0.05mol / L, 0.1mol / L, 0.2mol / L and 0.3mol / L POM-A solution.

[0058] 2. Redox reaction between anolyte (POM-A) and agricultural waste

[0059] Take 30mL of POM-A solutions of four different concentrations prepared respectively, and mix them with 0.6g of straw samples (dry basis, main components shown in Table 1) successively, and in phosphoric acid (85%, 0.45mL) Continue heating at ℃ for 2 hours, after the end, cool and filter the insoluble matter.

[0060] 3. Preparation of catholyte (POM-B)

[0061] vanadanomolybdate H 12 [P 3 Mo 18 V 7 o 85 ] As the catholyte, the solution concentration is 0.3mol / L, the volume of the cathode solution is 30mL, and the volume ratio of the anode and cathode solution is 1:1.

[0062] 4. Direct low-quality agricultural waste fuel cell assembly and testing methods

[0063] The agricultural waste ...

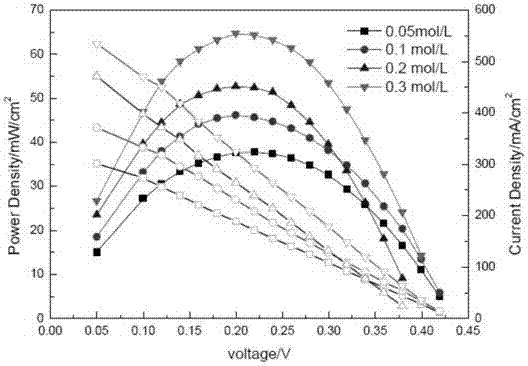

Embodiment 2

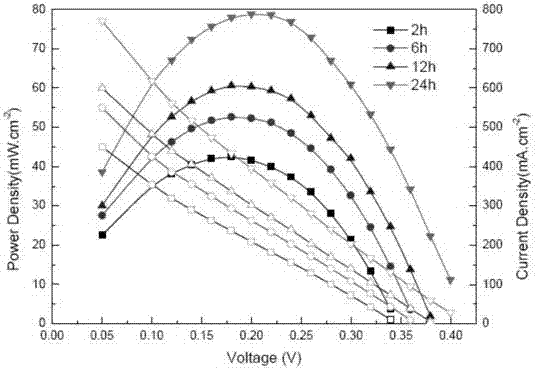

[0071] The fuel cell anode catalyst, cathode catalyst, fuel cell system, and the treatment temperature and method of preheating the agricultural waste and the anode catalyst in this embodiment are the same as those in Embodiment 1, except that the agricultural waste is different. In this example, 0.6 g of distiller's grains sample was used as the agricultural waste (dry basis, the main components are shown in Table 2). The electrochemical performance test data of the present embodiment are as image 3 shown.

[0072] Table 2 Main components of distiller's grain samples

[0073]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com