Chemical tin immersion plating solution used for suppressing tin whisker growth of printed circuit board and plating method

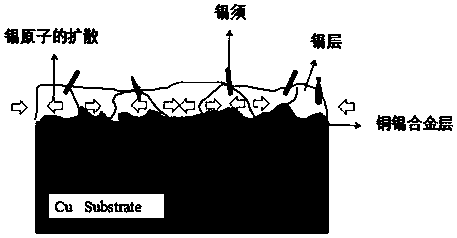

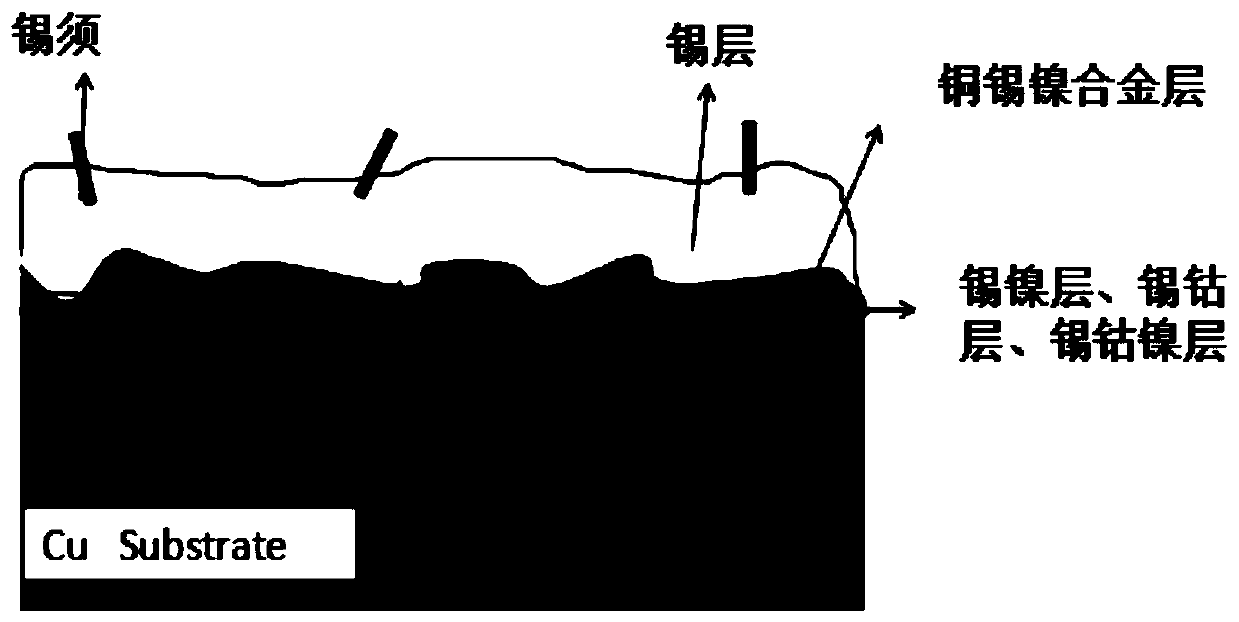

A printed circuit board, printed circuit technology, applied in liquid chemical plating, metal material coating process, coating, etc. Solderability and other issues, to achieve the effect of increasing the rate of tin plating, reducing the growth of tin whiskers, and inhibiting the growth of tin whiskers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

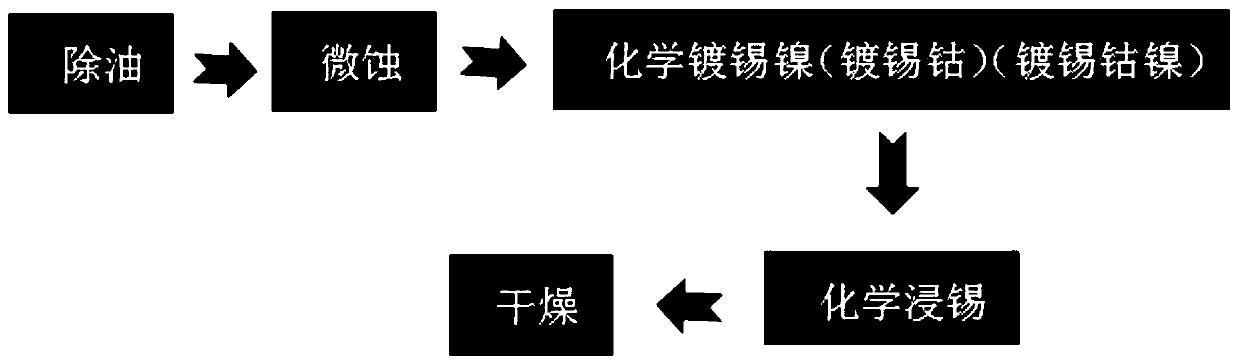

Method used

Image

Examples

Embodiment 1

[0032] The standard industrial chemical plating pure tin process is used to prepare samples: the base material of chemical plating is FR-4S1141 copper-clad laminate, the temperature of chemical plating solution is 45°C, the pH value is 0.8, and the time is 25min. 1h high temperature annealing treatment.

Embodiment 2

[0034] The electroless tin plating solution and the plating method for reducing the growth of tin whiskers described in this embodiment are specifically carried out according to the following steps:

[0035] 1. Substrate pre-treatment

[0036] The FR-4S1141 copper clad laminate was degreased and pickled. The degreasing temperature was 55°C, the degreasing time was 5 minutes, the pickling temperature was normal temperature, and the time was 60 seconds. After deionized water washing, the pretreated copper clad laminate was obtained.

[0037] The degreasing liquid is an acidic degreasing liquid, containing 5% sulfuric acid by mass, 1 ppm-10% surfactant by mass, and the like; the pickling liquid is prepared by 5% sulfuric acid by mass.

[0038] Substrate microetching

[0039] Acidic micro-etching was performed on the pretreated copper clad laminate, the microetching temperature was 25° C., the microetching time was 60 seconds, and the microetched copper clad laminate was obtained a...

Embodiment 3

[0050] The electroless tin plating solution and the plating method for reducing the growth of tin whiskers described in this embodiment are specifically carried out according to the following steps:

[0051] The FR-4S1141 copper clad laminate was degreased and pickled. The degreasing temperature was 55°C, the degreasing time was 5 minutes, the pickling temperature was normal temperature, and the time was 60 seconds. After deionized water washing, the pretreated copper clad laminate was obtained.

[0052] The degreasing liquid is an acidic degreasing liquid, containing 5% sulfuric acid by mass, 1ppm-10% surfactant by mass and other substances; the pickling liquid is prepared by 5% sulfuric acid by mass.

[0053] Substrate microetching

[0054] Acidic micro-etching was performed on the pretreated copper clad laminate, the microetching temperature was 25° C., the microetching time was 60 seconds, and the microetched copper clad laminate was obtained after deionized water washing....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com