Chemical immersion tin plating solution and preparation method thereof

A technology of chemical immersion plating and tin liquid, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of poor process stability and short service life, and achieve the promotion of film formation and coating solderability. Good, easy wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

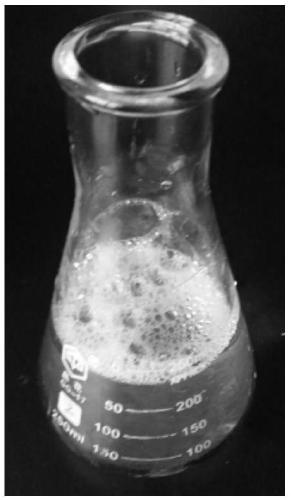

Image

Examples

Embodiment 1

[0027] The electroless tin plating solution of the present embodiment comprises the following components by concentration: 20g / L of tin salt, 80g / L of accelerator, 0.2g / L of wetting agent, 170g / L of stabilizer; Wherein: described tin salt is formazan Tin protosulfonate 20g / L; The accelerator is thiourea 80g / L, ammonium bifluoride 0.1g / L; The wetting agent is alkylphenol polyoxyethylene ether 0.2g / L, and the stabilizer is Methanesulfonic acid 150g / L, tartaric acid 20g / L.

[0028] The preparation method of the electroless tin-plating solution of the present embodiment, comprises the steps:

[0029] (1) Dissolve 150g of methanesulfonic acid and 20g of tartaric acid in 500ml of deionized water, and stir until dissolved;

[0030] (2) Add 80g of thiourea and 0.1g of ammonium bifluoride to the above solution, and stir until dissolved;

[0031] (3) Add 0.2g of alkylphenol polyoxyethylene ether and stir until dissolved;

[0032] (4) Chemical immersion tin plating liquid: use 200ml d...

Embodiment 2

[0045] The electroless tin plating solution of the present embodiment comprises the following components according to concentration: tin salt 10g / L, accelerator 80g / L, wetting agent 0.2g / L, stabilizer 170g / L;

[0046] Wherein: the tin salt is stannous sulfate 10g / L; the accelerator is methylthiourea 80g / L, sodium fluoride 0.1g / L; the wetting agent is polyethylene glycol (M=600) 0.2g / L, described stabilizing agent is methanesulfonic acid 150g / L, tartaric acid 20g / L; The preparation method of the chemical immersion tin plating solution of the present embodiment, comprises the steps:

[0047] (1) Use deionized water to dissolve a certain amount of methanesulfonic acid, and fully stir until dissolved;

[0048](2) Add quantitative methylthiourea and sodium fluoride to the above solution, fully stir until dissolved;

[0049] (3) Add quantitative polyethylene glycol again, fully stir until dissolving;

[0050] (4) Chemical immersion tin plating solution: finally add stannous sulfat...

Embodiment 3

[0063] The electroless tin plating solution of the present embodiment comprises the following components by concentration: tin salt 15g / L, accelerator 80g / L, wetting agent 0.2g / L, stabilizer 120g / L;

[0064] Wherein: the tin salt is stannous chloride 15g / L; the accelerator is thiourea 80g / L, ammonium bifluoride 0.1g / L. The wetting agent is 0.2g / L of alkylphenol polyoxyethylene ether, and the stabilizer is 100g / L of sulfuric acid and 20g / L of citric acid; the preparation method of the chemical immersion tin plating solution of the present embodiment comprises the following steps :

[0065] (1) Use deionized water to dissolve quantitative sulfuric acid, fully stir until dissolved;

[0066] (2) Add quantitative thiourea and ammonium bifluoride to the above solution, fully stir until dissolved;

[0067] (3) Add quantitative alkylphenol polyoxyethylene ether, fully stir until dissolved;

[0068] (4) Chemical immersion tin plating solution: add a certain amount of stannous chlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com