Preparation method of surface coating of zirconium alloy cladding and surface coating

A surface coating, zirconium alloy technology, applied in metal material coating process, coating, ion implantation plating and other directions, can solve the problems of radioactive material leakage, cladding tube embrittlement, zirconium alloy corrosion, etc. Low technology, high temperature stability, dense and uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

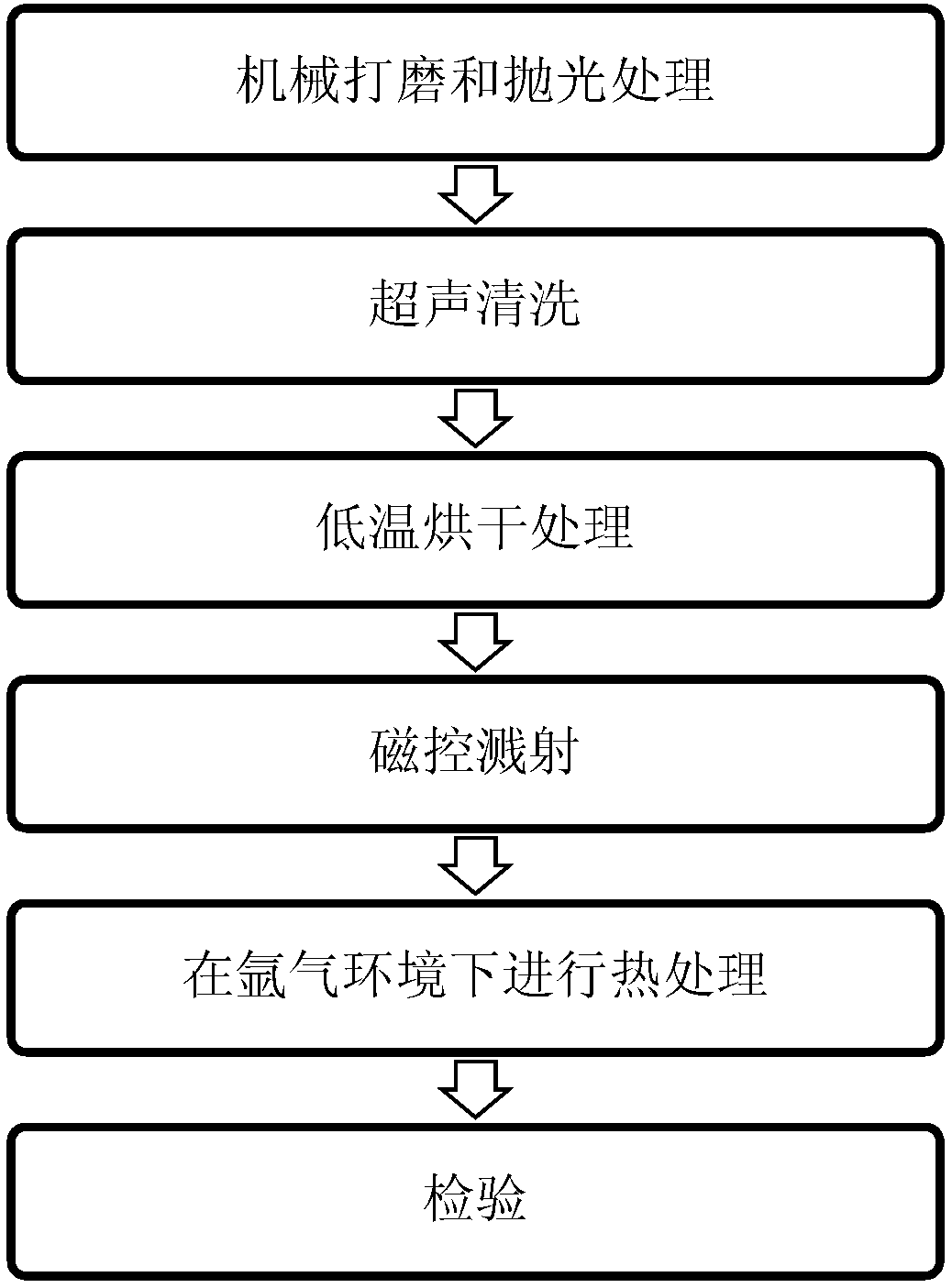

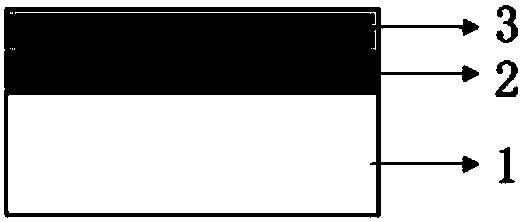

[0040] Specifically, the preparation method includes the following steps (combining figure 1 ):

[0041]A zirconium alloy substrate is provided, and the zirconium alloy substrate can be a block substrate and a tubular substrate;

[0042] The zirconium alloy block and tubular substrates are mechanically ground and polished. First, the zirconium alloy substrates are polished several times with 80-mesh to 5000-mesh sandpaper, and then polished, and then placed in a solution composed of acetone and deionized water. Wash for 5-10 minutes, and dry at low temperature;

[0043] Fix the sample (zirconium alloy substrate) after the above treatment in the fixture of the magnetron sputtering apparatus, adjust the target base distance between 40-80mm, and pump the background vacuum to the highest value that the equipment can reach 10 -6 The order of magnitude of Pa. The temperature of the chamber is controlled at room temperature (20°C) to 600°C, and the chamber pressure is adjusted wit...

no. 1 example

[0054] First Example: Single Carbide Coating

[0055] First prepare the zirconium alloy bulk and tubular substrates, wherein the bulk substrate is a zirconium alloy plate with a size of 20mm×20mm×5mm, and the tubular substrate is a zirconium alloy tube with a size of Φ9.5mm, a thickness of 0.57mm and a length of 200mm. For the above zirconium alloy The substrate is mechanically ground and polished. First, the zirconium alloy substrate is polished several times with 80-mesh to 5000-mesh sandpaper, then polished, and then ultrasonically cleaned in a solution composed of acetone and deionized water for 10 minutes, and then dried at a low temperature. deal with.

[0056] Fix the sample after the above treatment in the fixture of the magnetron sputtering apparatus, adjust the base distance of the target at 60 mm, and pump the background vacuum to 10 -3 Pa order of magnitude. The chamber temperature is controlled from room temperature to 400°C. Use argon to adjust the air pressur...

no. 2 example

[0059] Second Example: Composite Carbide Coating

[0060] First prepare the zirconium alloy bulk and tubular substrates, wherein the bulk substrate is a zirconium alloy plate with a size of 20mm×20mm×5mm, and the tubular substrate is a zirconium alloy tube with a size of Φ9.5mm, a thickness of 0.57mm and a length of 200mm. For the above zirconium alloy The substrate is mechanically ground and polished. First, the zirconium alloy substrate is polished several times with 80-mesh to 5000-mesh sandpaper, then polished, and then ultrasonically cleaned in a solution composed of acetone and deionized water for 10 minutes, and then dried at a low temperature. deal with.

[0061] Fix the sample after the above treatment in the fixture of the magnetron sputtering apparatus, adjust the target base distance to 80mm, and pump the background vacuum to 10 -4 Pa. The chamber temperature is controlled from room temperature to 400°C. Use argon to adjust the air pressure of the chamber so tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com