Preparation method of oil pipeline nano-composite coating

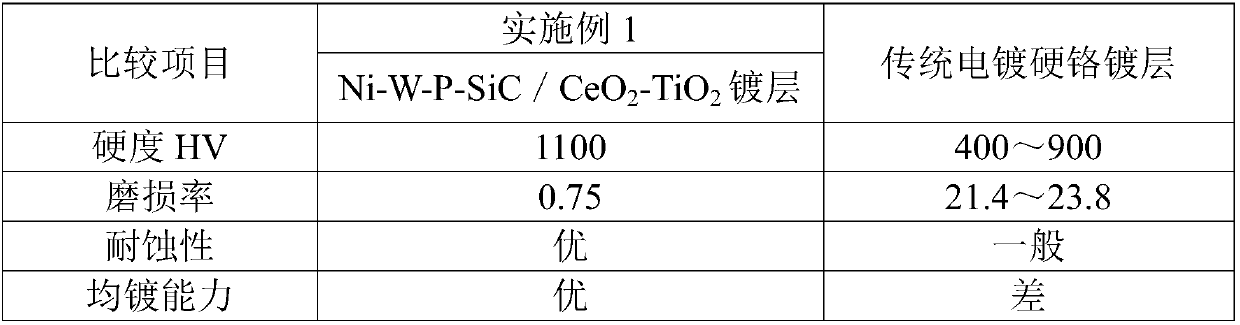

A nano-composite coating and oil pipeline technology, which is applied to coatings, electrolytic coatings, etc., can solve the problems of not being able to have anti-corrosion, anti-scaling, cationic wax, anti-wear, short product life of oil pipelines, and high drilling costs at the same time. Achieve the effect of shortening electrodeposition time, improving hardness and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below.

[0024] The preparation method of the oil pipeline nanocomposite coating of the present invention comprises the following steps:

[0025] (1) Pretreatment of oil pipeline plating parts:

[0026] ① Grind and polish the plated parts of ordinary carbon steel oil pipelines with sandpaper, wash them with tap water, and put them in 20-60°C containing H 2 SO 4 Or in acidic solution of HCl, activate for 2min.

[0027] ②Then use ordinary carbon steel oil pipeline plating parts as cathodes and graphite as anodes, separate them and place them in the electroplating solution, and directly coat a layer of nickel film on the surface of ordinary carbon steel oil pipeline plating parts; nano-SiC, CeO 2 and TiO 2 Particles are introduced into the electrodeposition plating solution, and metal-based Ni-W-P-SiC / CeO is prepared on the surface of ordinary carbon steel oil pipelines by electrodeposition using bidirectional h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com