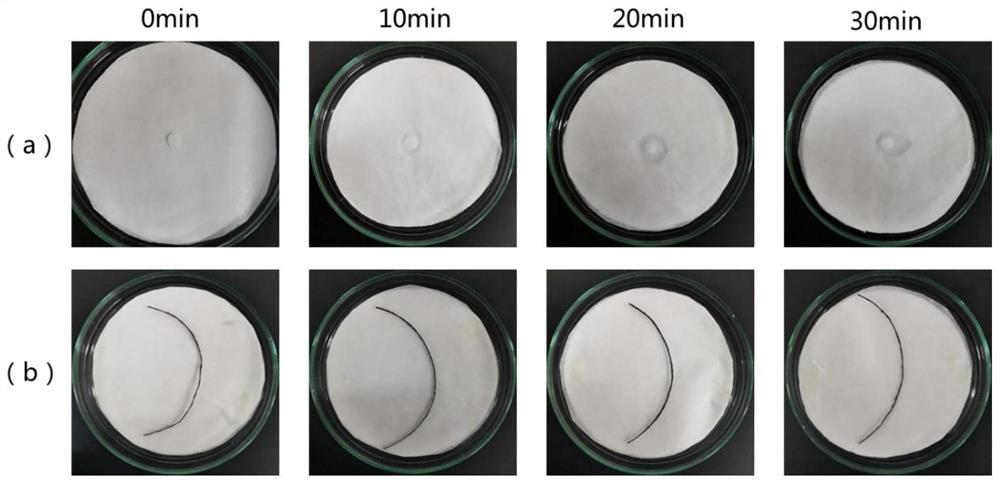

Sized and coated photo-thermal phase change composite yarn and preparation method thereof

A composite yarn and coating technology, which is applied in fiber types, textiles and papermaking, and fiber processing, can solve the problems of light-to-heat conversion synergistic phase change temperature adjustment functions, less functional research, and low production efficiency, etc. High heat conversion efficiency, simple preparation method, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

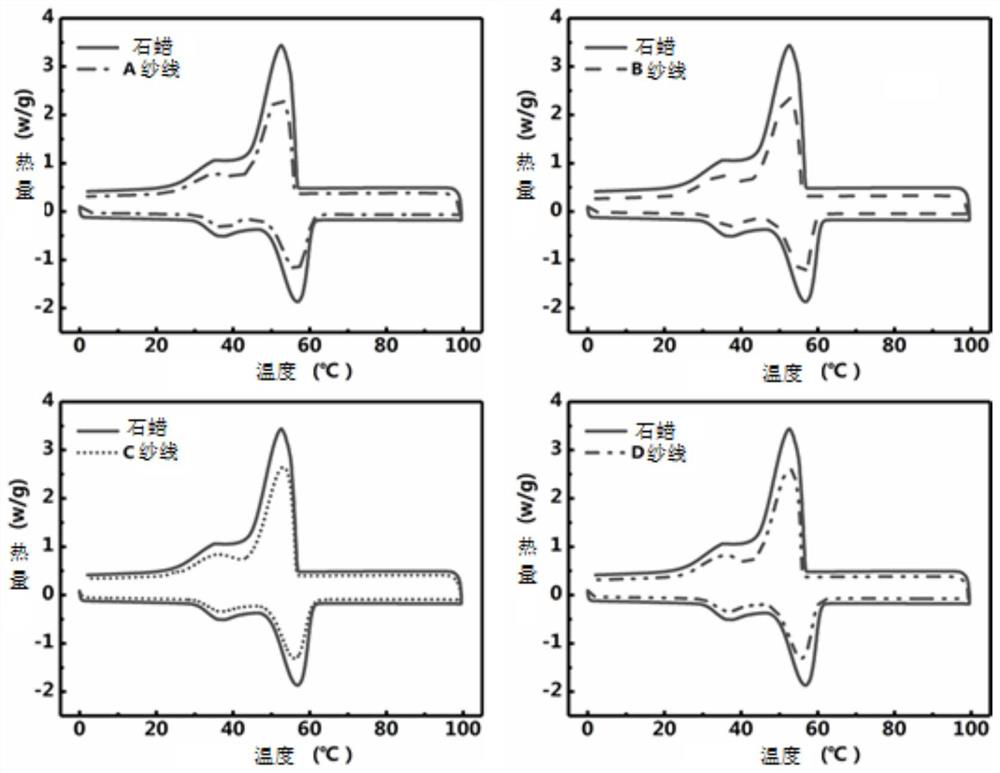

Embodiment 1

[0019] 1) Prepare 5.9% polyvinyl butyral / 5% zirconium carbide / 0.5% alumina suspension. Add polyvinyl butyral to absolute ethanol, stir mechanically until the solution is evenly mixed, then add zirconium carbide particles and alumina and continue stirring for a period of time, and finally ultrasonically treat to obtain uniformly dispersed 5% polyvinyl butyral / 5% zirconium carbide / 0.5% alumina suspension;

[0020] 2) Put a beaker containing a certain amount of paraffin into a magnetic stirrer in a water bath at 80°C and stir until the paraffin is completely melted, then set aside.

[0021] 3) Pour the molten paraffin and polyvinyl butyral / zirconium carbide / alumina suspension into the two sizing tanks of the sizing machine respectively, and then introduce the polyester yarn (20S / 2) through the yarn guide device first Go to the size tank (80°C) filled with molten paraffin, the sizing speed is 1.8m / min, and then pass through the size tank (room temperature) with polyvinyl butyral...

Embodiment 2

[0024] 1) Prepare 5.9% polyvinyl butyral solution. Add polyvinyl butyral to absolute ethanol, and mechanically stir until the solution is uniformly mixed to obtain a uniformly mixed 5.9% polyvinyl butyral solution;

[0025] 2) Put a beaker containing a certain amount of paraffin into a magnetic stirrer in a water bath at 80°C and stir until the paraffin is completely melted, then set aside.

[0026] 3) Pour the molten paraffin and polyvinyl butyral solutions into the two sizing tanks of the sizing machine respectively, and then introduce the polyester yarn into the sizing tank containing the molten paraffin through the yarn guide device, and then pass through A size tank equipped with polyvinyl butyral solution passes through pressing rollers, a drying room, and a winding device to obtain polyester / paraffin / PVB composite yarn (B yarn). The temperature of the polyvinyl butyral solution size tank is room temperature, the temperature of the molten paraffin slurry tank is 80°C, t...

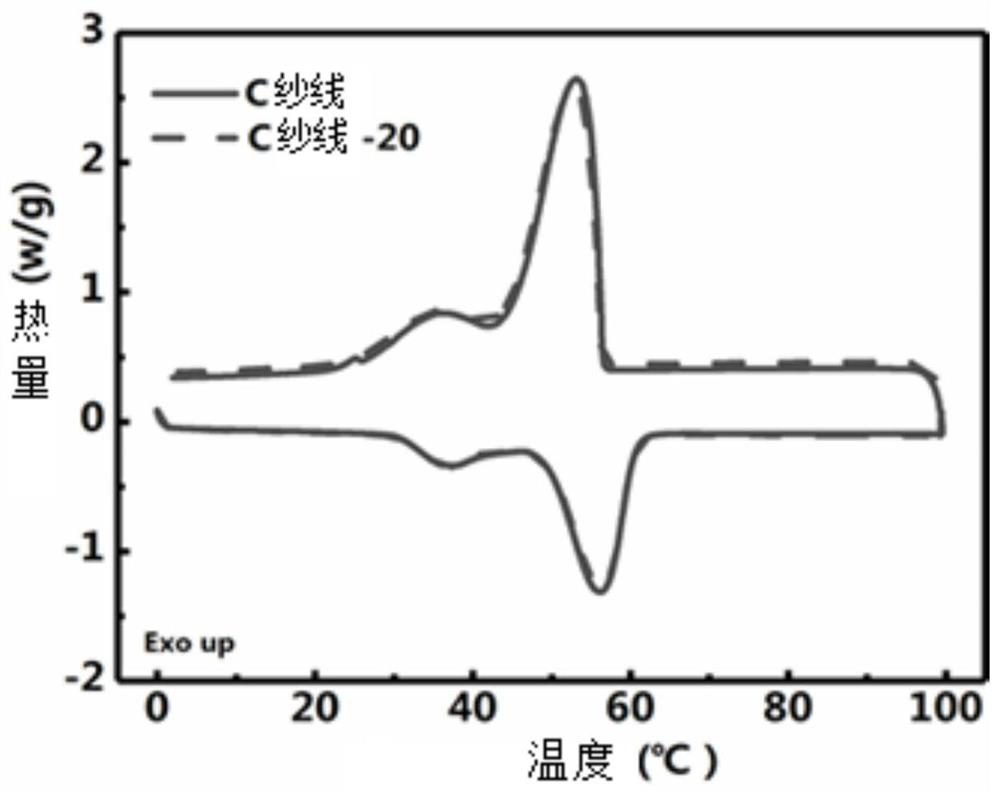

Embodiment 3

[0029] 1) Prepare 5.9% polyvinyl butyral / 5% zirconium carbide / 0.5% alumina suspension. Add polyvinyl butyral to absolute ethanol, mechanically stir until the solution is evenly mixed, then add zirconium carbide particles and alumina and continue stirring for a period of time, and finally obtain uniformly dispersed 5.9% polyvinyl butyral by ultrasonic treatment / 5% zirconium carbide / 0.5% alumina suspension;

[0030] 2) Introduce polyester into a slurry tank equipped with 5.9% polyvinyl butyral / 5% zirconium carbide / 0.5% alumina suspension, and obtain polyester / PVB / ZrC / Al through pressing rollers, drying room, and winding device 2 o 3 / composite yarn;

[0031] 3) Put a beaker containing a certain amount of paraffin into a magnetic stirrer in a water bath at 80°C and stir until the paraffin is completely melted, then set aside.

[0032] 4) Pour the molten paraffin and the polyvinyl butyral / zirconium carbide / alumina suspension into the two sizing tanks of the sizing machine respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com