Zirconium carbide/polypyrrole-polyurethane composite fiber and preparation method and application thereof

A composite fiber and zirconium carbide technology, applied in the field of composite fibers, can solve the problem of no research report on polypyrrole and zirconium carbide composite particles, and achieve the effects of easy promotion, simple steps and unique technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

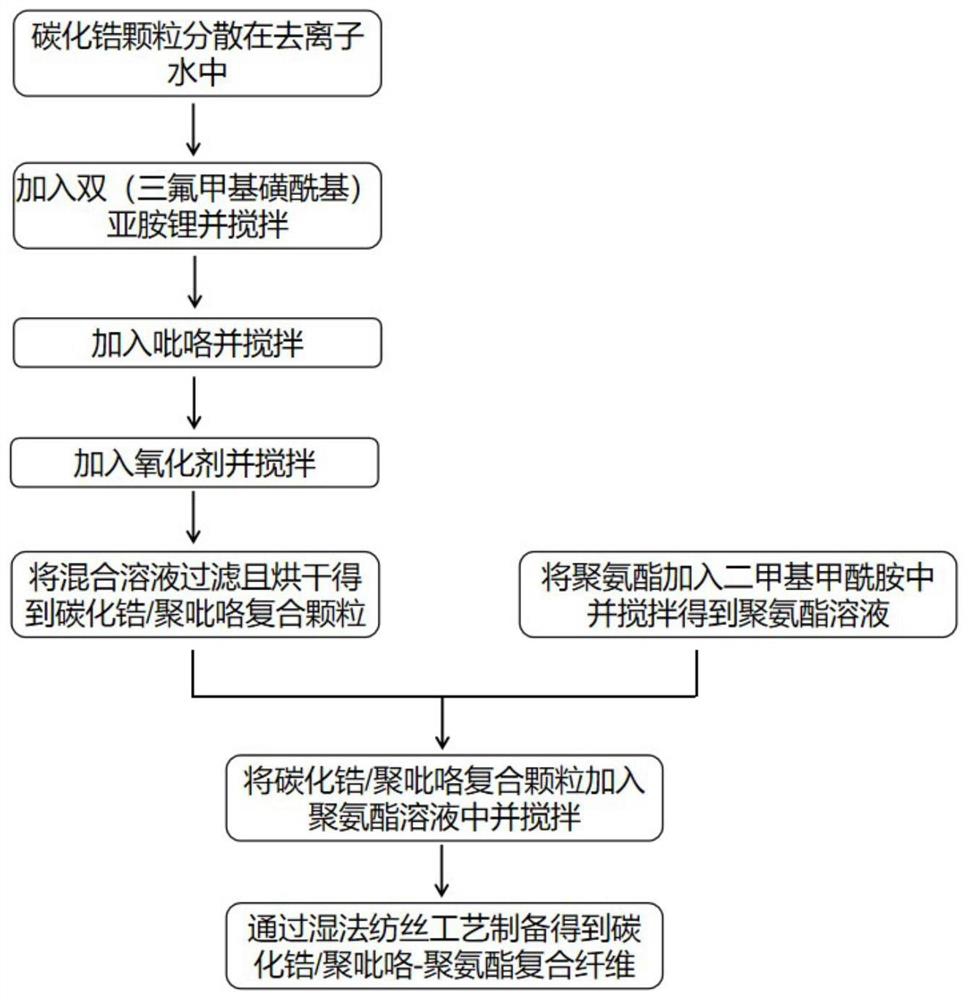

[0043] like figure 1 Shown, the preparation method of zirconium carbide / polypyrrole-polyurethane composite fiber of the present invention comprises the steps:

[0044] (1), adding zirconium carbide particles, lithium bis(trifluoromethylsulfonyl)imide, pyrrole and oxidant into deionized water and stirring to obtain a zirconium carbide / polypyrrole solution, and then filtering the zirconium carbide / polypyrrole solution and drying to obtain zirconium carbide / polypyrrole composite particles;

[0045] (2), polyurethane is dissolved in dimethylformamide and stirred, obtains polyurethane solution;

[0046] (3), zirconium carbide / polypyrrole composite particles are dispersed in polyurethane solution to obtain zirconium carbide / polypyrrole-polyurethane spinning solution;

[0047] (4) The zirconium carbide / polypyrrole-polyurethane spinning solution is wet-spun to obtain the zirconium carbide / polypyrrole-polyurethane composite fiber.

[0048] Wherein, in step (1), the oxidant is select...

Embodiment

[0064] The preparation method of the zirconium carbide / polypyrrole-polyurethane composite fiber of the present embodiment comprises the steps:

[0065] (1), adding zirconium carbide, bis(trifluoromethylsulfonyl)imide lithium, pyrrole and ferric chloride (as oxidizing agent) into deionized water successively and stirring, the stirring speed is 5rpm, the time is 10min, and the temperature is 0 ℃, obtain zirconium carbide / polypyrrole solution, then zirconium carbide / polypyrrole solution is filtered and dried to obtain zirconium carbide / polypyrrole composite particles; wherein, the content of zirconium carbide in water is 5wt%, bis(trifluoromethyl The content of lithium sulfonyl)imide is 3wt%, the content of pyrrole is 3wt%, the molar ratio of oxidant and pyrrole is 2.5:1, and the temperature of zirconium carbide / polypyrrole solution is 0°C.

[0066] (2) Polyurethane was dissolved in dimethylformamide and stirred, the stirring speed was 150rpm, the time was 5h, and the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com