EVA (Ethylene Vinyl Acetate) master batch as well as preparation method and application thereof

A technology of color masterbatch and luminous powder, which is applied in the field of polymer materials, can solve problems such as easy sedimentation, poor compatibility, and blackening of products, and achieve enhanced dispersion and bonding firmness, improving bonding fastness, and luminous intensity enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

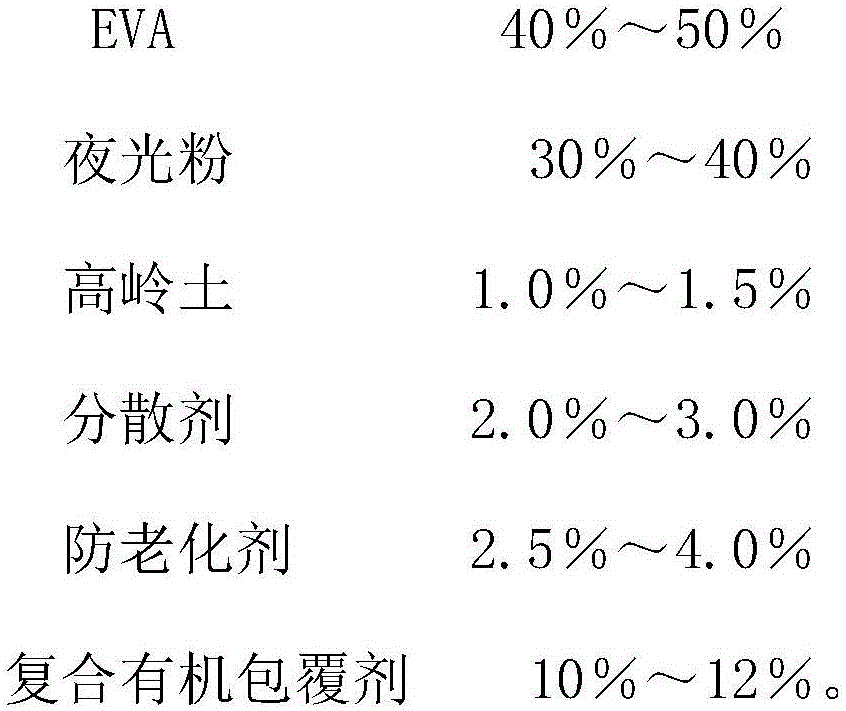

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of this EVA masterbatch comprises following specific steps:

[0027] 1) Weigh the luminous powder and the composite organic coating agent according to the designed formula, put them into chloroform solvent at 40°C and react for 6 hours to prepare the composite luminous powder;

[0028] 2) Weigh EVA, kaolin, dispersant, anti-aging agent and the composite luminous powder prepared in step 1) according to the designed formula, mix them and put them into the internal mixer for internal mixing;

[0029] 3) Put the mixed material into a three-roller grinder for grinding, the temperature of the grinder is 80°C-160°C, and the speed ratio of the three rollers is 1:(2-4):(4-16) , the preferred speed ratio is 1:2:4;

[0030] 4) Transport the ground material to a single-screw extruder for granulation and drying, the extrusion temperature is 175°C-180°C, and the extrusion pressure is 3.2MPa-3.4MPa.

Embodiment 1

[0033] The EVA masterbatch is composed of the following mass percentages of raw materials: 44% EVA; 38% luminous powder; 1.0% kaolin; 2.7% dispersant; 3.5% anti-aging agent; 10.8% composite organic coating agent .

[0034] Wherein, the VA content of the EVA is 18%-25%, and the melt index is 20g / 10min-40g / 10min. The luminous powder is SrAl in the alkaline earth aluminate system long afterglow luminous powder 2 o 4 :Eu 2+ , Dy 3+ , the particle size is 12μm~20μm. The composite organic coating agent is composed of maleic anhydride and gemini surfactant in a weight ratio of 5:1, the content of maleic anhydride is 9% of the total weight of raw materials, and the content of gemini surfactant is 1.8% of the total weight of raw materials. The dispersant is 1.2% polyethylene wax and 1.5% stearic acid amide, and the percentage base of polyethylene wax and stearic acid amide is the sum of all raw material weights.

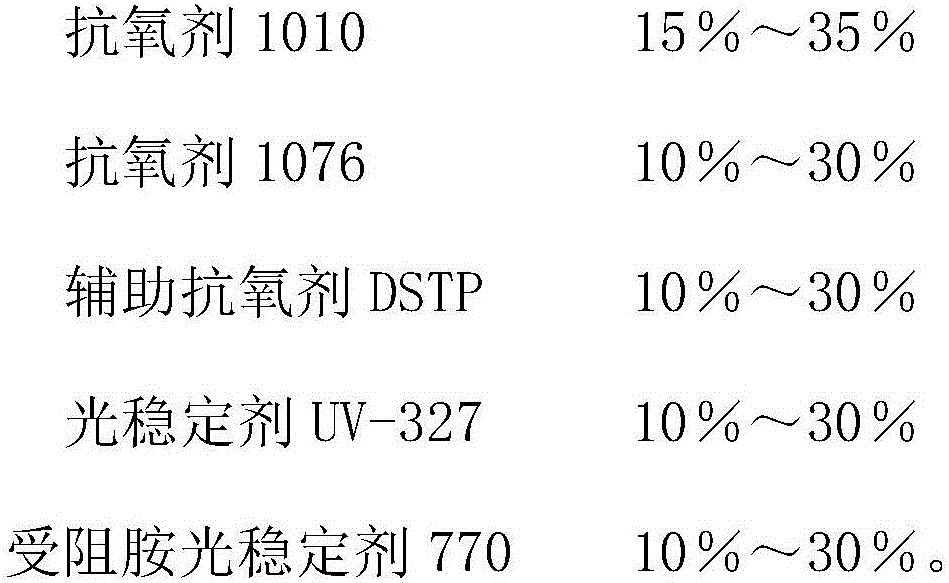

[0035] Described antiaging agent is by the antioxidant 1010 of 0.4...

Embodiment 2

[0037] The EVA masterbatch is composed of the following mass percentages of raw materials: 40% EVA; 40% luminous powder; 1.5% kaolin; 2.5% dispersant; 3.5% anti-aging agent; 12% composite organic coating agent .

[0038] Wherein, the VA content of the EVA is 18%-25%, and the melt index is 20g / 10min-40g / 10min. The luminous powder is SrAl in the alkaline earth aluminate system long afterglow luminous powder 2 o 4 :Eu 2+ , Dy 3+ , the particle size is 12μm~20μm. The composite organic coating agent is composed of maleic anhydride and gemini surfactant in a weight ratio of 5:1, the content of maleic anhydride is 10% of the total weight of raw materials, and the content of gemini surfactant is 2% of the total weight of raw materials. The dispersant is 1.8% polyethylene wax and 1.7% stearic acid amide, and the percentage bases of polyethylene wax and stearic acid amide are the sum of all raw material weights.

[0039]Described antiaging agent is by the auxiliary antioxidant DST...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com