Method for preparing nanotube composite membrane photo-anode through hydrothermal method

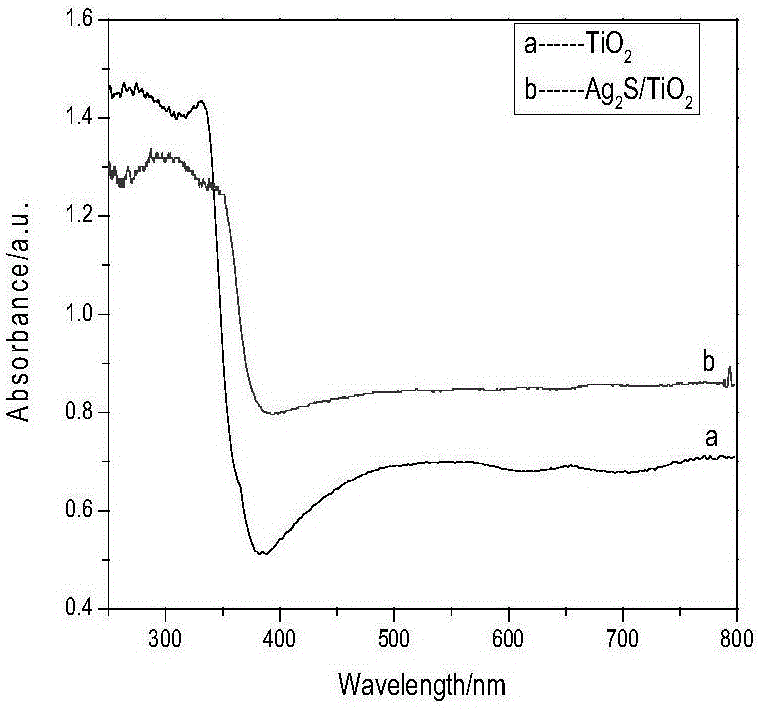

A composite film and photoanode technology, which is applied in the field of Ag2S/TiO2 composite film photoanode preparation by hydrothermal method, can solve the problems of ineffective use of visible light, etc., and achieve the effects of saving raw materials, easy control of conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of hydrothermal method prepares Ag 2 S / TiO 2 The method for composite film photoanode, comprises the following steps:

[0042] A titanium sheet with a size of 20*20*0.1mm was cut from a titanium foil with a purity of more than 99.9% as the substrate, cleaned ultrasonically in acetone, absolute ethanol, and deionized water in sequence, and dried in the air for use.

[0043] 0.45g NH 4 F dissolved in 2.5mL H 2 O, then add 6mL H 2 o 2 and 6mL HNO 3 Make it into a polishing solution, put the cleaned titanium sheet into the polishing solution and polish it for 30 seconds, then wash it with a large amount of distilled water and dry it for later use.

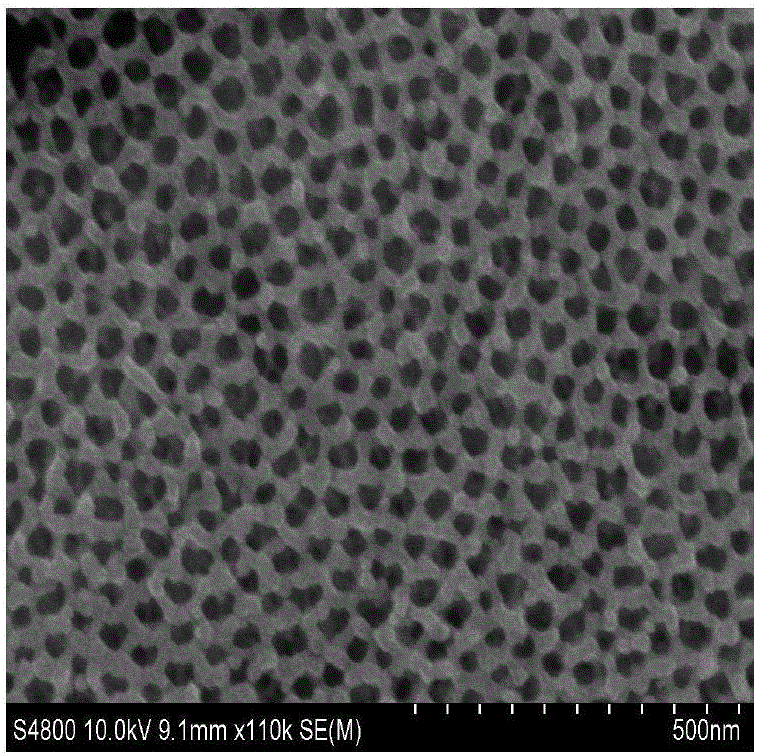

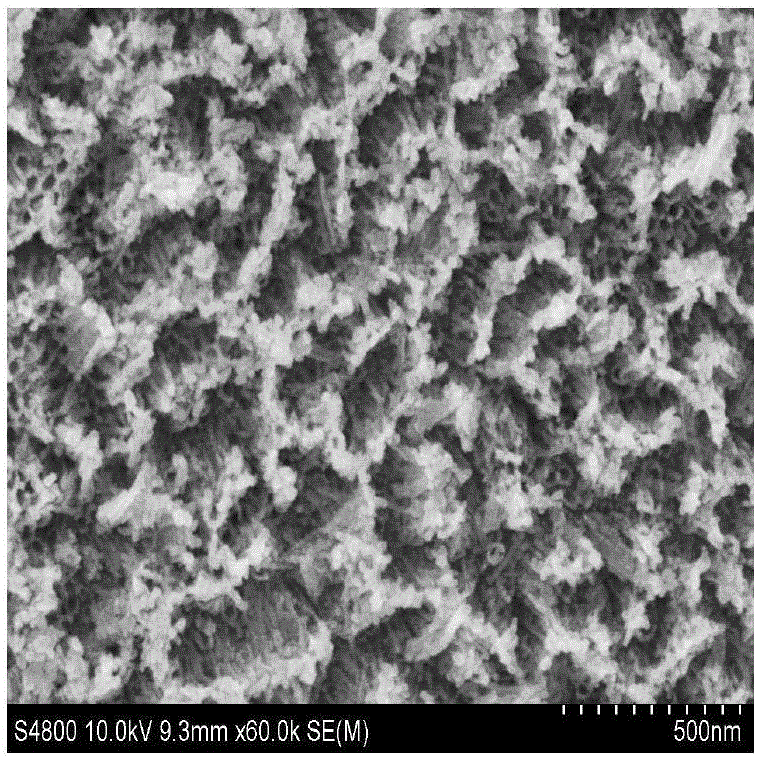

[0044] Weigh 0.22g NH 4 Dissolve F in 1.5mL deionized water, add 40mL ethylene glycol and stir evenly as electrolyte. At room temperature, the treated titanium substrate was used as the anode, and the platinum sheet was used as the cathode, anodized at 20V in the electrolyte for 0.5 hours, ultrasonically cleaned, ...

Embodiment 2

[0055] A kind of Ag for photogenerated cathodic protection 2 S / TiO 2 The preparation of composite film photoanode comprises the following steps:

[0056] A titanium sheet with a size of 20*20*0.1mm was cut from a titanium foil with a purity of more than 99.9% as the substrate, cleaned ultrasonically in acetone, absolute ethanol, and deionized water in sequence, and dried in the air for use.

[0057] 0.45g NH 4 F is dissolved in 2.5m LH 2 O, then add 6mL H 2 o 2 and 6mL HNO 3 Make it into a polishing solution, put the cleaned titanium sheet into the polishing solution and polish it for 30 seconds, then wash it with distilled water and dry it for later use.

[0058] Weigh 0.22g NH 4F, dissolved in 1.5mL deionized water, added 40mL ethylene glycol and stirred evenly as the working solution. At room temperature, the treated titanium substrate is used as the anode, and the platinum sheet is used as the cathode. After anodizing at 20V for 0.5 hours in electrolysis, ultrasoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com