Hot dipping steel and manufacturing method thereof

A manufacturing method and hot-dip plating technology, applied in hot-dip plating process, coating, metal material coating process and other directions, can solve the problems of inability to meet the protection effect of aluminum plate, weak cathodic protection effect, etc., to optimize the hot-dip plating process , Improve cathodic protection ability, enhance the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

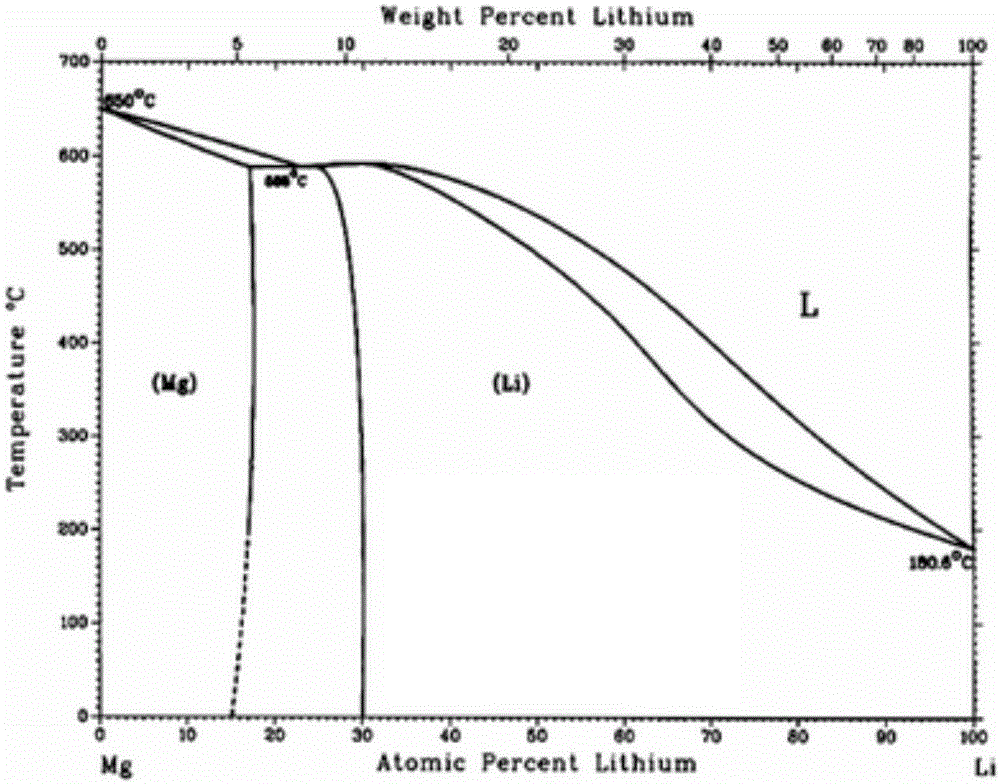

[0046] The embodiment of the present application provides a hot-dip galvanized steel and its manufacturing method, which suppresses the formation of flow lines in the hot-dip galvanized steel coating, adds alloy elements to improve the cathodic protection capability, and obtains excellent cathodic protection performance for aluminum plates and a good coating. The appearance is hot-dip galvanized steel, and the corrosion resistance has also been improved to a certain extent.

[0047] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

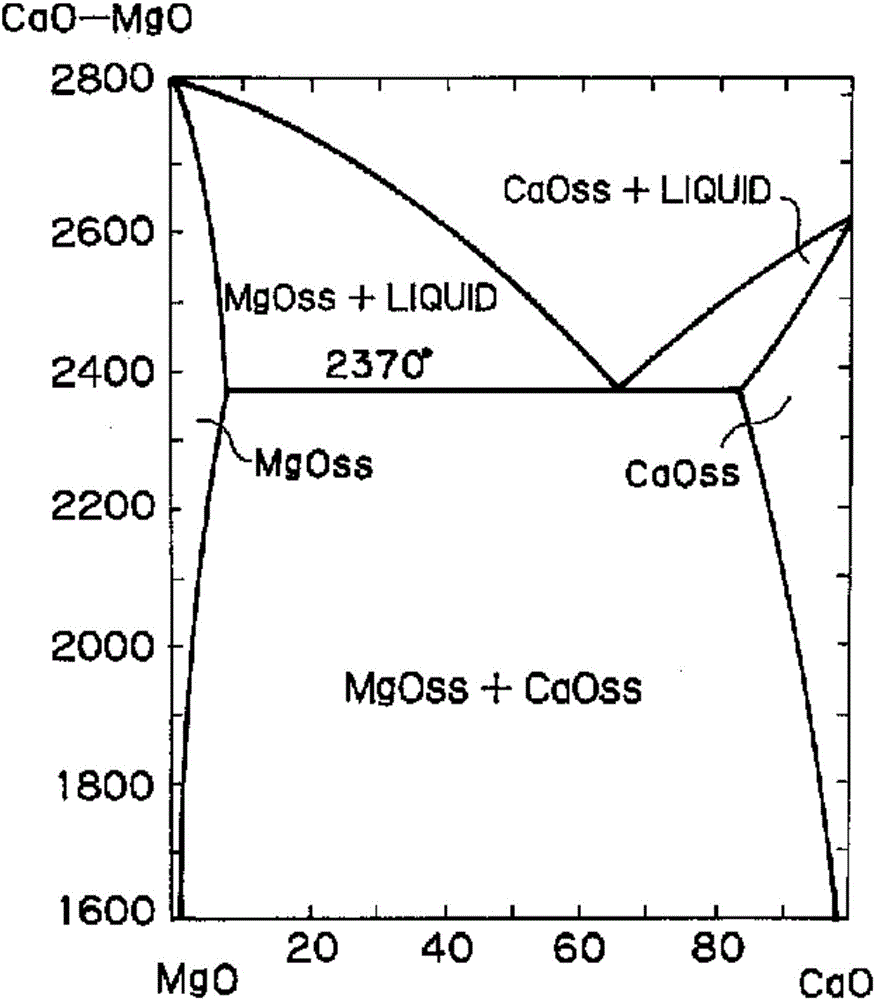

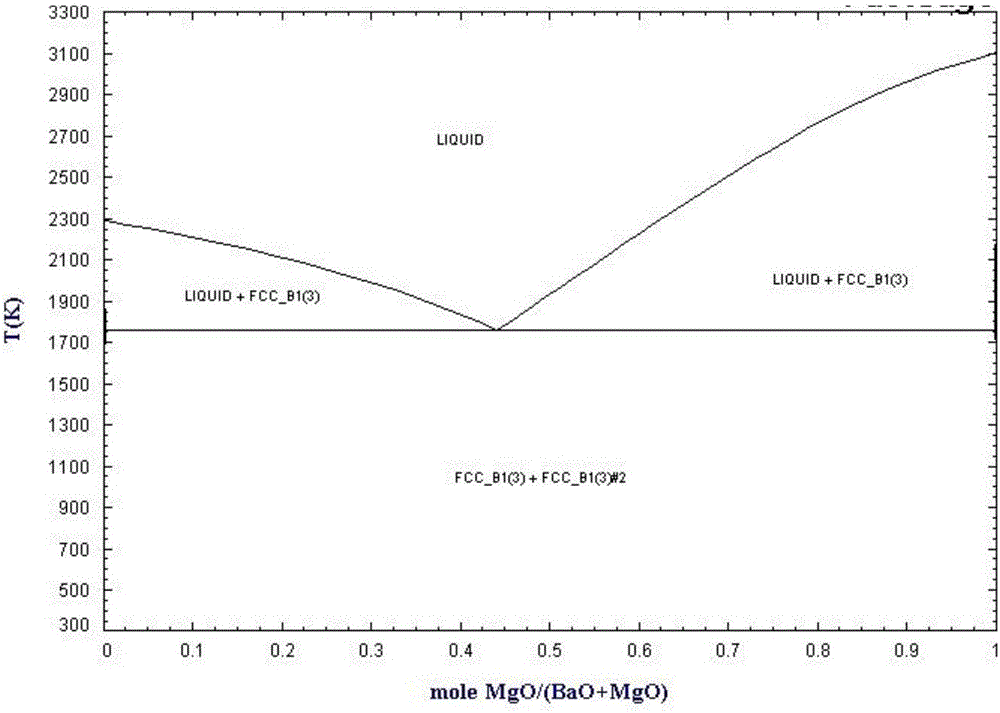

[0048] The hot-dipped steel according to the present embodiment is obtained by forming a Zn-Al-Mg alloy coating on the surface of a steel base. Examples of steel substrates include various members such as steel plates, steel wires, steel pipes, and the like. The plating lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com