Heavy-duty graphene primer for ocean ships and preparation method thereof

A heavy-duty anti-corrosion primer and graphene technology, applied in the direction of anti-corrosion coatings, coatings, conductive coatings, etc., can solve the problems of long-term anti-corrosion performance and wide applicability without in-depth research, and achieve social and economic benefits Sustained development, compactness and barrier properties strengthen firmness, enhance the effect of salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

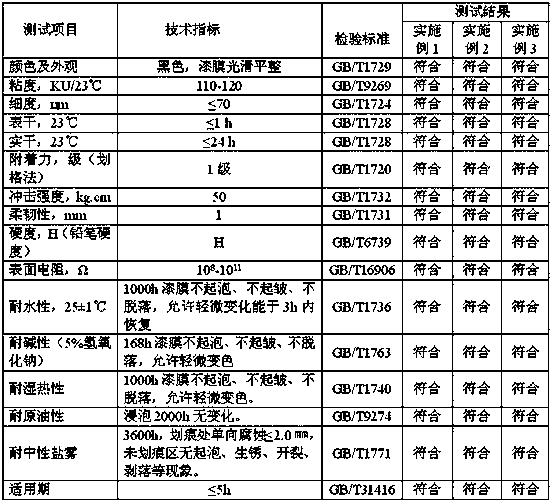

Examples

Embodiment 1

[0047] A kind of multifunctional nano-graphene heavy-duty anti-corrosion primer for warships, the mass parts of each component are as follows:

[0048] Component A (main paint):

[0049] Component Mass parts

[0050] Modified epoxy resin 135

[0051] Wetting and dispersing additive 3

[0052] Antifoam 2

[0053] Organic bentonite 10

[0055] Fumed silica 8

[0056] n-Butanol 30

[0057] Xylene 30

[0058] Low Surfactant 3

[0059] 800 mesh mica iron oxide 30

[0060] 800 mesh mica powder 50

[0061] 800 mesh composite iron titanium powder 350

[0062] Zinc powder 300

[0063] Nanoscale Graphene 10

[0064] Diphenylguanidine chromate 5

[0065] Xylene 16

[0066] B component (curing agent):

[0067] Component Mass parts

[0068] Xylene 39

[0069] n-Butanol 13

[0070] Epoxy Accelerator 2

[0071] Modified amine 10

[0072] Polyamide 36

[0073] The ratio of component A to component B is 10:1.

Embodiment 2

[0075] A kind of multifunctional nano-graphene heavy-duty anti-corrosion primer for warships, the mass parts of each component are as follows:

[0076] Component A (main paint):

[0077] Component Mass parts

[0078] Modified epoxy resin 140

[0079] Wetting and dispersing additive 4

[0080] Antifoam 2

[0081] Organic bentonite 11

[0083] Fumed silica 9

[0084]n-Butanol 30

[0085] Xylene 28

[0086] Low Surfactant 4

[0087] 800 mesh mica iron oxide 25

[0088] 800 mesh mica powder 45

[0089] 800 mesh composite iron titanium powder 330

[0090] Zinc powder 330

[0091] Nanoscale Graphene 11

[0092] Diphenylguanidine chromate 8

[0093] Xylene 5

[0094] B component (curing agent):

[0095] Component Mass parts

[0096] Xylene 38

[0097] n-Butanol 13.5

[0098] Epoxy Accelerator 2.5

[0099] Modified amines 9

[0100] Polyamide 37

[0101] The ratio of component A to component B is 10:1.

Embodiment 3

[0103] A kind of multifunctional nano-graphene heavy-duty anti-corrosion primer for warships, the mass parts of each component are as follows:

[0104] Component A (main paint):

[0105] Component Mass parts

[0106] Modified epoxy resin 150

[0107] Wetting and dispersing additive 5

[0108] Antifoam 3

[0109] Organic bentonite 8

[0110] Polyamide Wax 20

[0111] Fumed silica 10

[0112] n-Butanol 25

[0113] Xylene 30

[0114] Low Surfactant 5

[0115] 800 mesh mica iron oxide 20

[0116] 800 mesh mica powder 40

[0117] 800 mesh composite iron titanium powder 300

[0118] Zinc powder 350

[0119] Nanoscale Graphene 12

[0120] Diphenylguanidine chromate 10

[0121] Xylene 12

[0122] B component (curing agent):

[0123] Component Mass parts

[0124] Xylene 37

[0125] n-Butanol 14

[0126] Epoxy Accelerator 3

[0127] Modified amines 8

[0128] Polyamide 38

[0129] The ratio of component A to component B is 10:1.

[0130] The preparation method of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com