Water-based heavy-duty anti-corrosive coating and preparation method thereof

A heavy-duty anti-corrosion and coating technology, applied in anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems of unmentioned reduction, and achieve the effect of improving cathodic protection, reducing usage, and improving shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

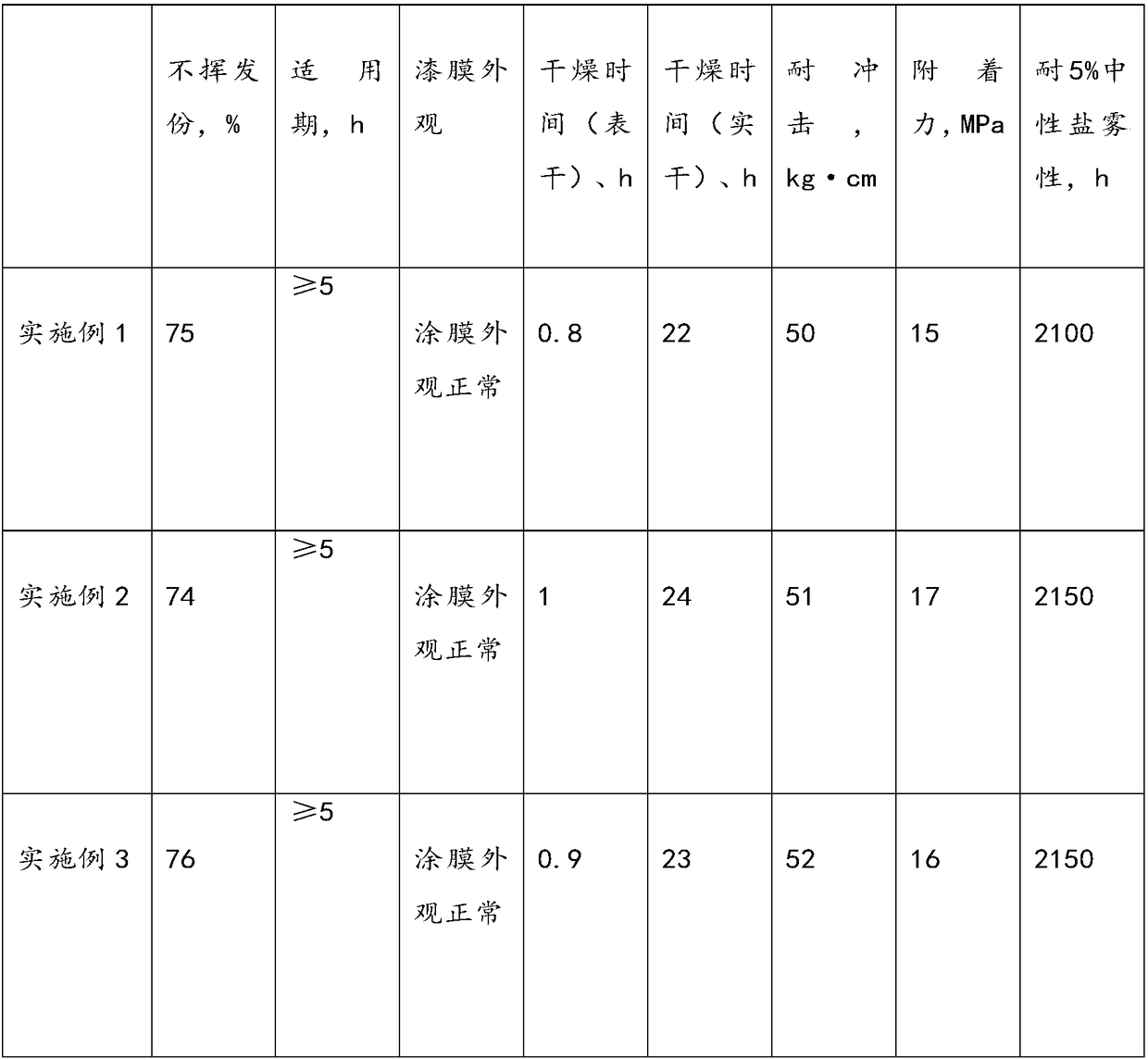

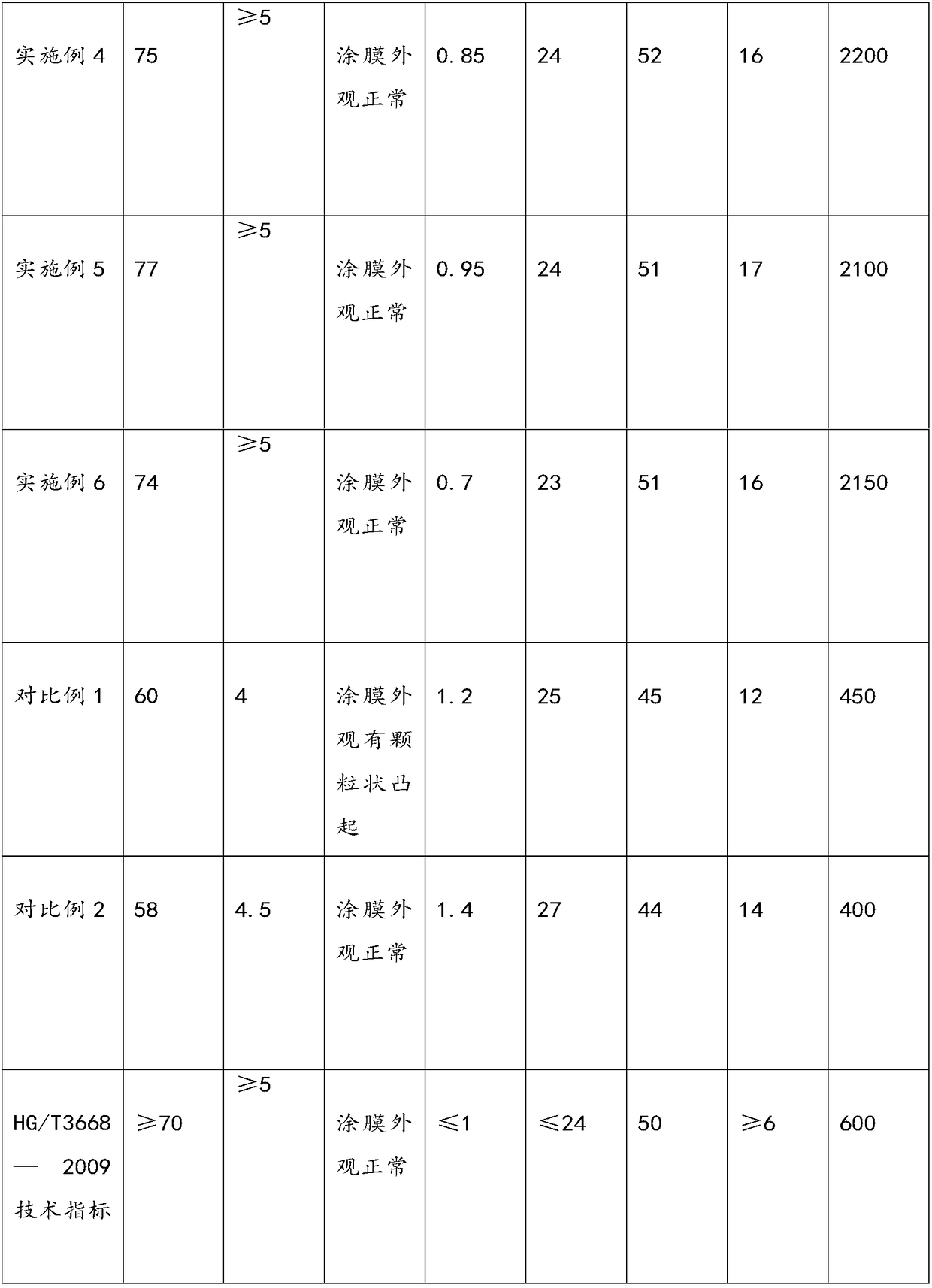

Examples

preparation example Construction

[0025] The embodiment of the present invention also provides a kind of preparation method of waterborne heavy-duty anticorrosion paint, comprises the following steps:

[0026] S1, preparing graphene slurry;

[0027] Disperse the graphene-like substances in the mixture of dispersant, wetting agent and hydrophilic organic solvent, and grind at the same time, so that the graphene-like substances can be fully dispersed in the hydrophilic organic solvent, which can effectively prevent the occurrence of graphene-like substances Agglomeration, and then ensure that graphene-like substances can fully exert their functions. Grinding while mixing is convenient for obtaining single-layer graphene-like substances, which is more conducive to graphene to exert its effect. Specifically, grind 3-5 times, and detect the particle size of the graphene-like substance in the hydrophilic organic solvent by a laser particle size analyzer. When the detected D90 is 0.8 microns, it means that the grind...

Embodiment 1

[0035] This embodiment provides a water-based heavy-duty anti-corrosion coating. The water-based heavy-duty anti-corrosion coating is composed of A component and B component, and the weight ratio of A component to the B component is 2:1.

[0036] Among them, component A includes 12Kg zinc powder, 0.2Kg graphene slurry, 20Kg anti-rust pigment, 5Kg anti-settling agent, 2Kg corrosion inhibitor, 0.5Kg dispersant, 0.3Kg leveling agent, 0.1Kg defoamer and 8Kg Hydrophilic epoxy curing agent. Among them, every Kg graphene slurry includes 1Kg graphene, 80Kg methyl pyrrolidone, 0.5Kg dispersant and 0.5Kg wetting agent; the anti-rust pigment is micaceous iron oxide red; the hydrophilic epoxy curing agent uses water as the dispersion medium modified amines.

[0037] Component B includes 90Kg of epoxy resin emulsion, and the epoxy resin emulsion is a water-based epoxy emulsion with an epoxy equivalent of 450.

[0038] Present embodiment also provides a kind of preparation method of waterbo...

Embodiment 2

[0046] This embodiment provides a water-based heavy-duty anti-corrosion coating. The water-based heavy-duty anti-corrosion coating is composed of A component and B component, and the weight ratio of A component to the B component is 6:1.

[0047] Among them, A component includes 40Kg zinc powder, 5Kg graphene slurry, 65Kg antirust pigment, 0.3Kg anti-settling agent, 0.1Kg corrosion inhibitor, 2Kg dispersant, 1Kg leveling agent, 0.3Kg defoamer and 25Kg pro Waterborne epoxy curing agent. Wherein, every Kg graphene slurry comprises 10Kg graphene, 90Kg dipropylene glycol methyl ether, 10Kg dispersant and 5Kg wetting agent; Antirust pigment is micaceous iron oxide ash; Hydrophilic epoxy curing agent is based on hydrophilic solvent Modified amines for dispersion media.

[0048] Component B includes 40Kg epoxy resin emulsion, 60Kg water and 0.5Kg bactericidal preservative, and the epoxy resin emulsion is a water-based epoxy emulsion with an epoxy equivalent of 1100.

[0049] Presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com