Preparation method of zinc-iron-aluminum hydrotalcite/titanium dioxide composite film photo-anode for photoproduction cathode protection

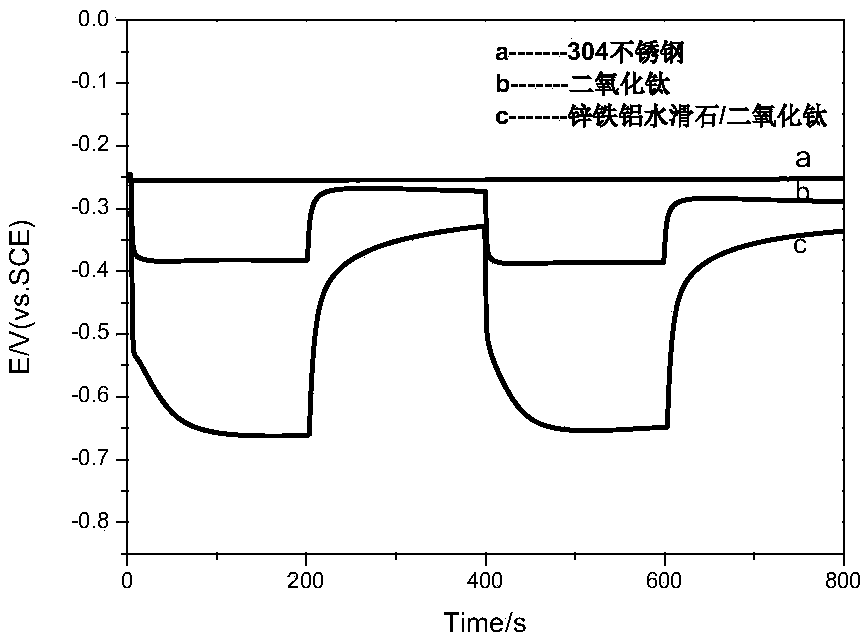

A technology of photogenerated cathodic protection and titanium dioxide, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of unrealized development, lower utilization efficiency of visible light, high recombination rate of photogenerated carriers, etc., and achieve improvement The effect of photogenerated carrier yield, increased light absorption range, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a zinc-iron-aluminum hydrotalcite / titanium dioxide composite film photoanode for photogenerated cathodic protection, comprising the following steps:

[0039] A titanium sheet with a size of 40*10*0.2mm is cut from a titanium foil with a purity greater than 99.9% as the substrate, ultrasonically cleaned in absolute ethanol and deionized water in sequence, and dried in the air for use.

[0040] 1.80g NH 4 F dissolved in 10.0 mL H 2 O, then add 24.0mL H 2 o 2and 24.0mL HNO 3 Make it into a polishing solution, put the cleaned titanium sheet into the polishing solution and polish it for 30 seconds, then wash it with a large amount of distilled water and dry it for later use.

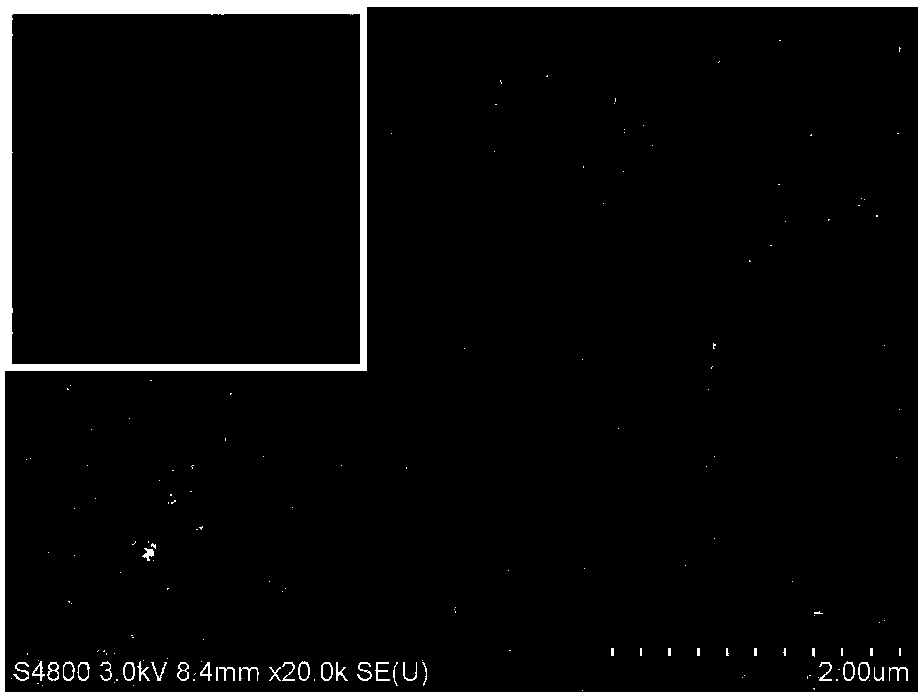

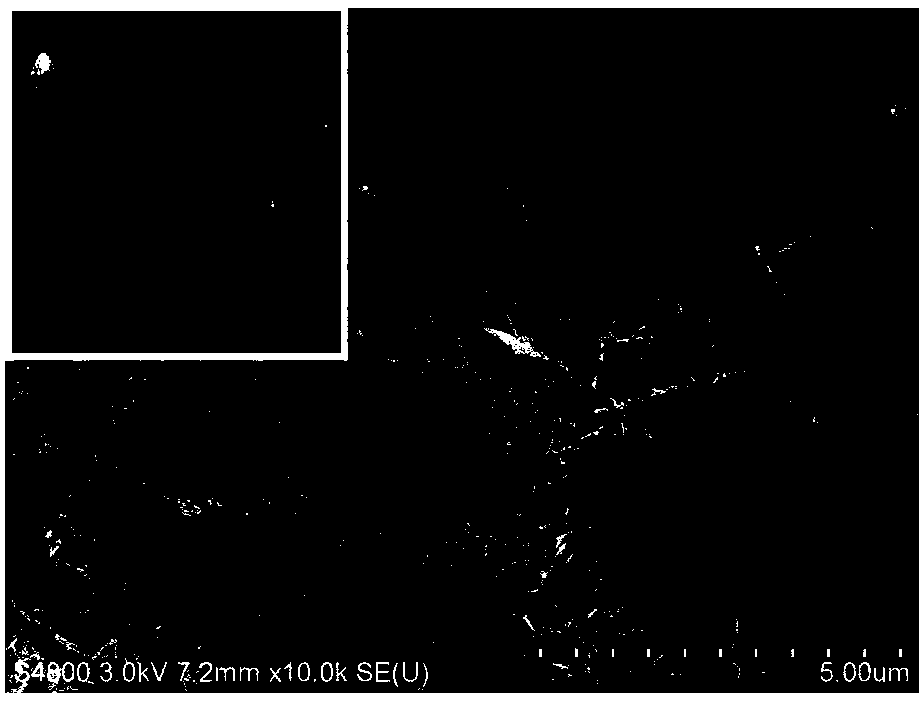

[0041] Weigh 0.44g NH 4 Dissolve F in 8mL deionized water, add 80mL ethylene glycol and stir evenly as electrolyte. At room temperature, the above-mentioned treated titanium substrate was used as the anode, and the platinum sheet was used as the cathode, and anodized at 20V...

Embodiment 2

[0050] A method for preparing a zinc-iron-aluminum hydrotalcite / titanium dioxide composite film photoanode for photogenerated cathodic protection, comprising the following steps:

[0051] A titanium sheet with a size of 40*10*0.2mm is cut from a titanium foil with a purity greater than 99.9% as the substrate, ultrasonically cleaned in absolute ethanol and deionized water in sequence, and dried in the air for use.

[0052] 0.45g NH 4 F dissolved in 2.5mL H 2 O, then add 6mL H 2 o 2 and 6mL HNO 3 Make it into a polishing solution, put the cleaned titanium sheet into the polishing solution and polish it for 30 seconds, then wash it with a large amount of distilled water and dry it for later use.

[0053] Weigh 0.44g NH 4 Dissolve F in 8mL deionized water, add 80mL ethylene glycol and stir evenly as electrolyte. At room temperature, the above-mentioned treated titanium substrate was used as the anode, and the platinum sheet was used as the cathode, and anodized at 20V in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com