Preparation method of SrTiO3 nano composite film photoanode

A nano-composite and photoanode technology, applied in the field of photoanode, can solve the problems of low photoelectric conversion efficiency, fast photo-generated carrier recombination speed, etc., and achieve good photoelectric effect, excellent photo-generated cathodic protection effect, coating and complete effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

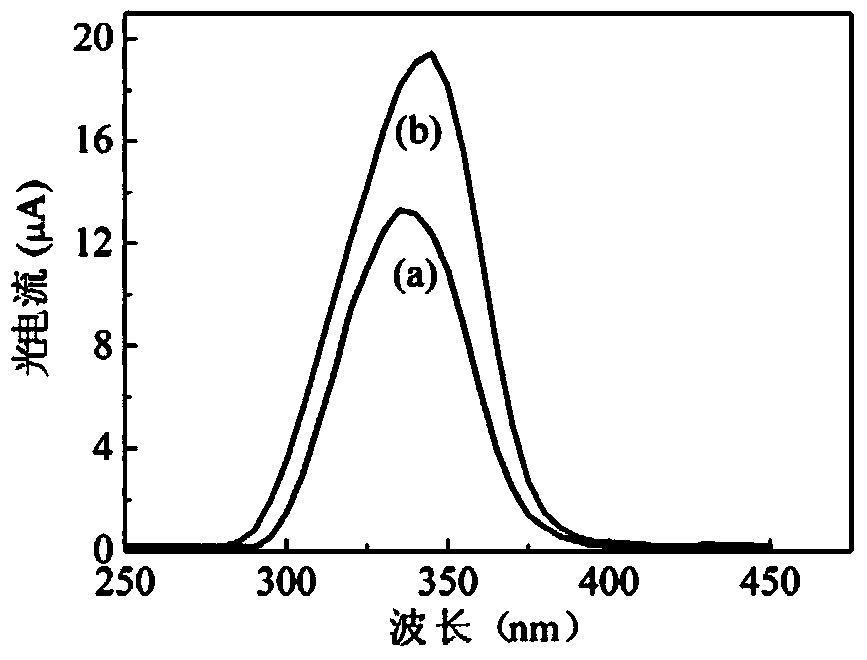

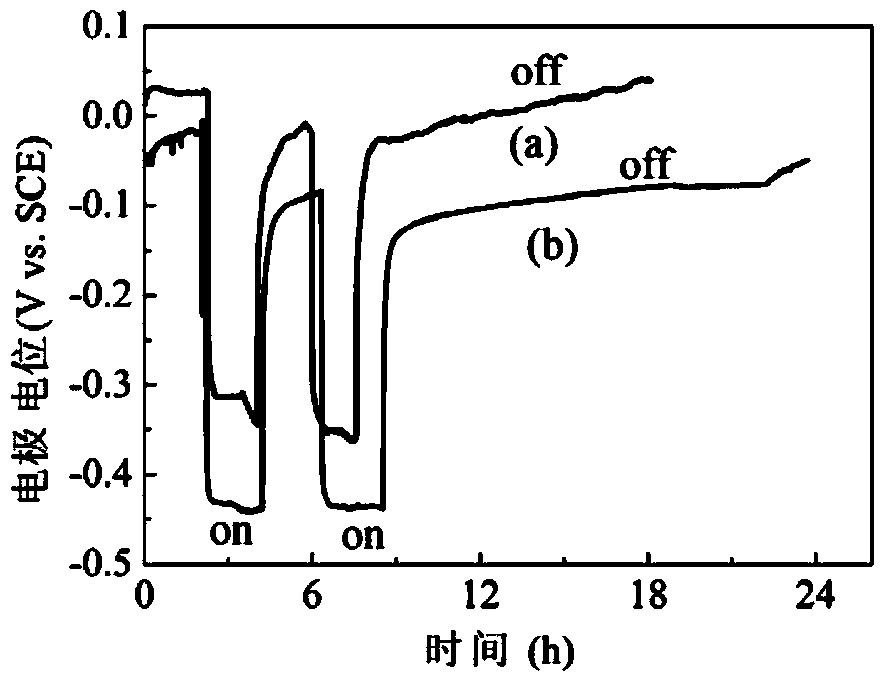

[0025] According to the above technical scheme (specific steps), prepare SrTiO 3 Nanocomposite film photoanode, and test the cathodic protection effect of the photoanode on 403 stainless steel.

[0026] Take a 0.1mm thick rectangular pure titanium foil as a sample (purity>99.7%), its length is 1.5cm, and its width is 1.0cm. Sequentially ultrasonic cleaning in acetone, absolute ethanol and deionized water for 30 min.

[0027] Anodizing solution composition: NH 4 F content is 0.5wt%, glycerol: water (volume ratio) = 3:2. With titanium foil as anode and platinum sheet as cathode, anodize in the above solution for 1h. After the reaction was completed, it was washed with a large amount of deionized water, dried, and put into a muffle furnace for heat treatment at 450° C. for 120 minutes.

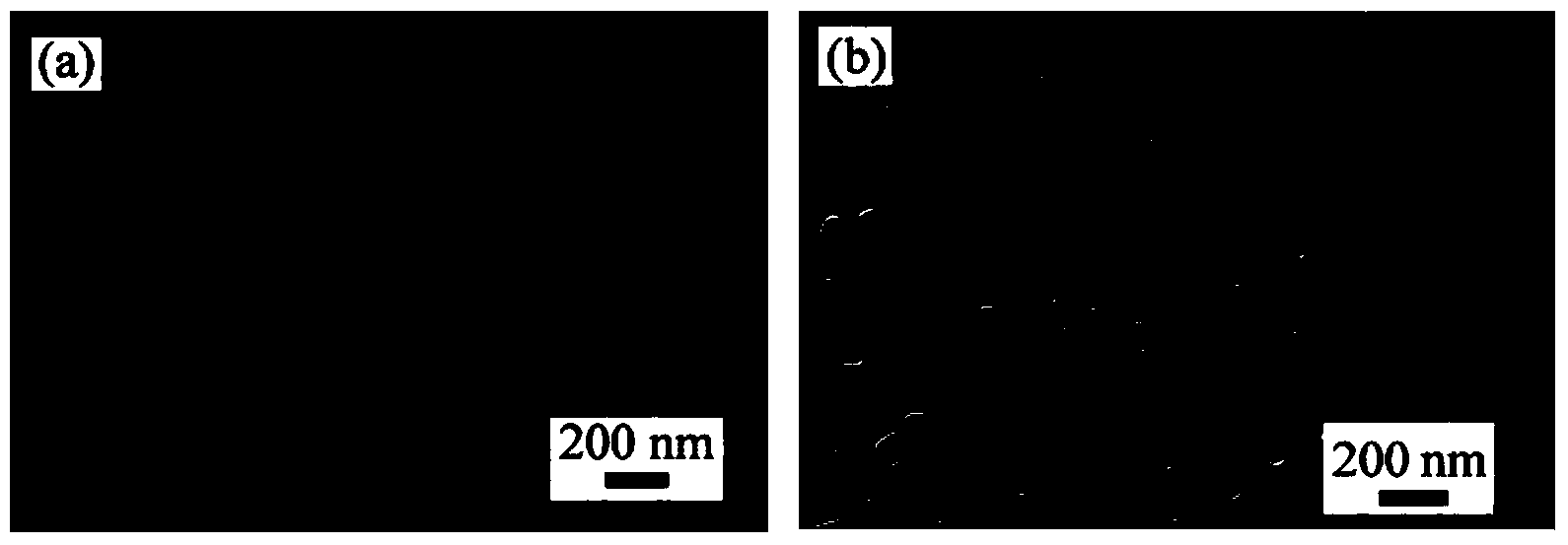

[0028] Cover the prepared surface with TiO 2 The titanium foil of the nanotube array film was placed in a polytetrafluoroethylene reactor, and 0.01M Sr(OH) was added 2 Solution 40mL, reacte...

Embodiment 2

[0035] Take a 0.1mm thick rectangular pure titanium foil as a sample (purity>99.7%), which is 1.5cm long and 1.0cm wide. Sequentially ultrasonic cleaning in acetone, absolute ethanol and deionized water for 30 min.

[0036] Anodizing solution composition: NH 4 F content is 0.5wt%, glycerol: water (volume ratio) = 3:2. With titanium foil as anode and platinum sheet as cathode, anodize in the above solution for 1h. After the reaction is finished, wash with a large amount of deionized water, dry and put it into a muffle furnace for heat treatment at 450°C for 120min.

[0037] Cover the prepared surface with TiO 2 The titanium foil of the nanotube array film was placed in a polytetrafluoroethylene reactor, and 0.01M Sr(OH) was added 2 Solution 40mL, react at 180°C for 1h, take out the sample and soak in 0.01M HCl solution for 1min, then rinse with a large amount of deionized water, dry and calcinate in a muffle furnace at 450°C for 120min. That is, the prepared SrTiO 3 and T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com