Insulating layer coating equipment for cable production and use method thereof

A technology for coating equipment and insulating layers, applied in the field of insulating layer coating equipment for cable production, can solve the problems of torsional force damage to the wire core, damage, etc., and achieve the effect of improving cooling efficiency and ensuring the integrity of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

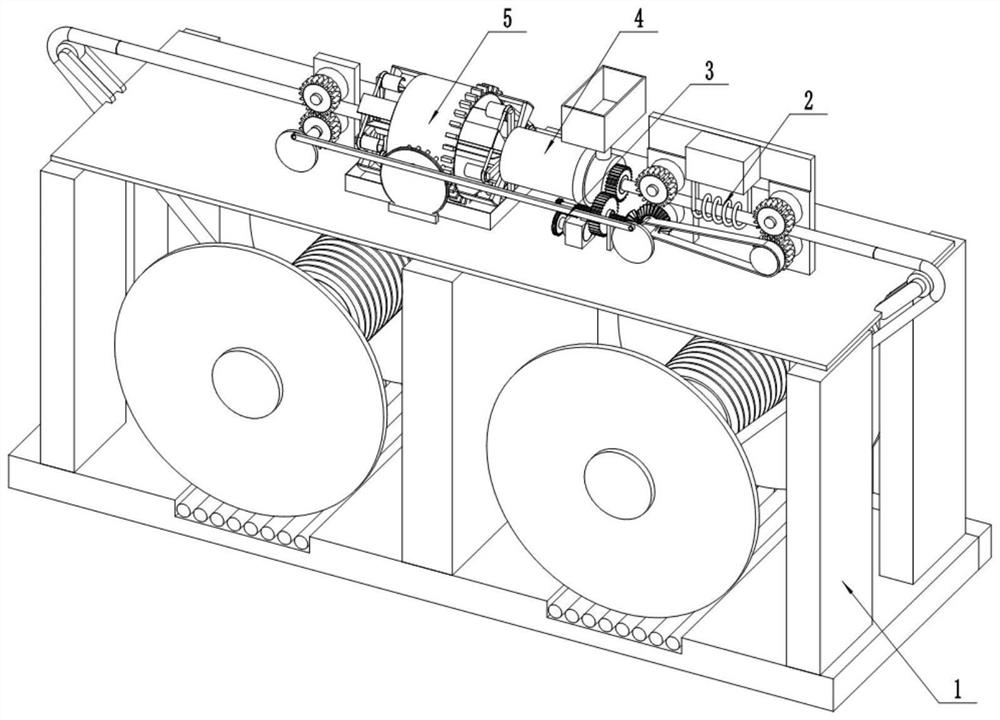

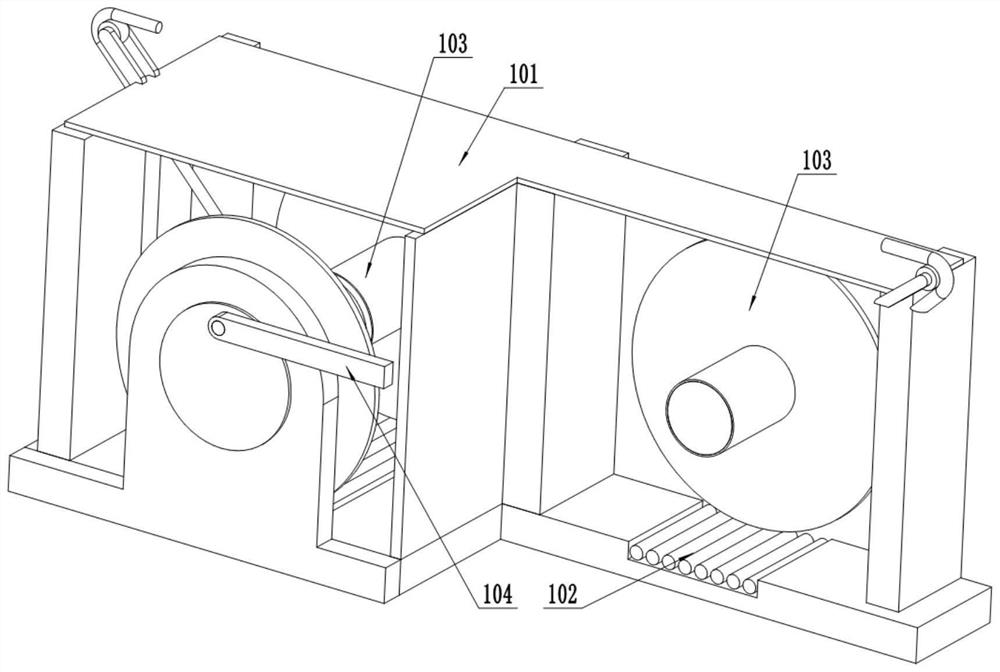

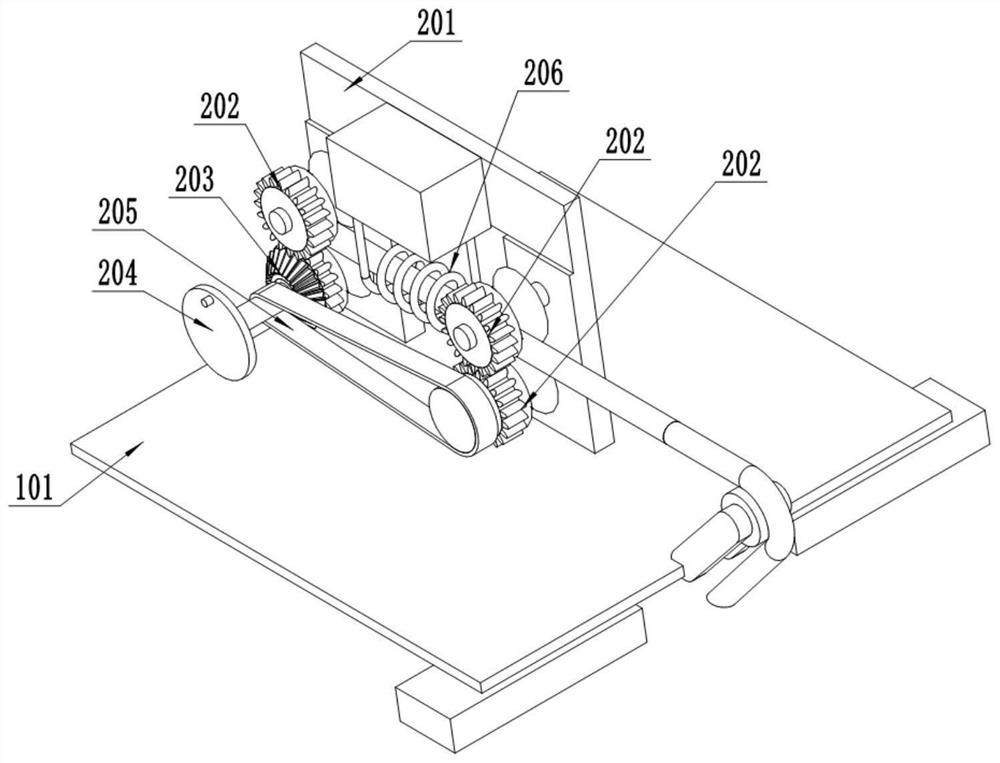

[0032] Example: Reference figure 1 The insulating layer coating equipment for cable production shown includes a winding assembly 1 provided with two winding wheels 103, and the winding assembly 1 is used to place uncoated cables and coated cables. The upper end of the winding assembly 1 is provided with a stretching assembly 2 for heating and stretching the cable, and the stretching assembly 2 is provided with a time-delay driving assembly 3 that controls the cable to enter the present invention and then wraps it. There is a feed assembly 4 which heats the raw material of the cladding layer and coats the cable on the cable through a spiral cone. The rear end of the feed assembly 4 is provided with a cooling assembly 5 which continuously sprays the coated cable with water.

[0033] refer to figure 1 and figure 2 As shown, the winding assembly 1 includes a base 101, and the base 101 is internally provided with two sets of winding wheels 103, and the lower end of each set of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com