Battery, negative electrode material and preparation method thereof

A negative electrode material and battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle performance and low electrical conductivity, and achieve the effect of improving electrical conductivity, high electrical conductivity, and improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

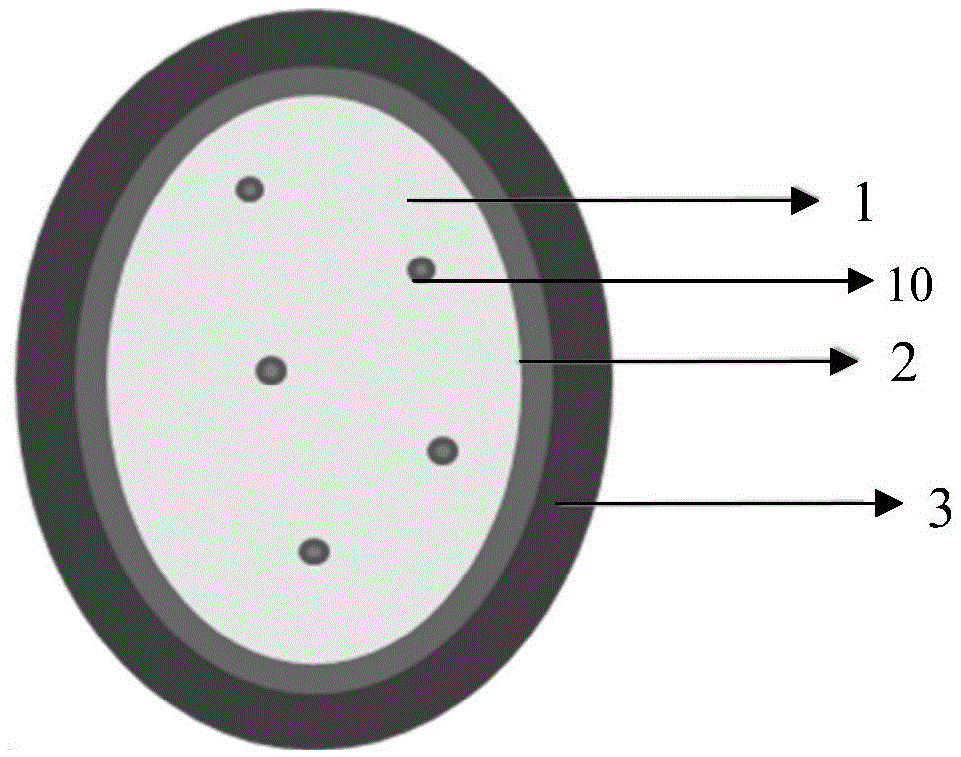

Image

Examples

preparation example Construction

[0028] The preparation method of the negative electrode material of the present invention includes the following steps:

[0029] (1) Configure silicon oxide (SiO x ): CO(NH 2 ) 2 :Metal salt molar ratio=30-100:3-15:1 mixed aqueous solution, and control the pH of the mixed solution to 1-6. Preferably, silicon oxide (SiO x The x value of) is 0.9-1.5, and the particle size of silicon oxide is 300nm-5000nm; preferably, the metal salt is: ferric chloride, cobalt chloride, nickel chloride, ferric sulfate, ferrous sulfate, cobalt sulfate, sulfuric acid Any one or more of nickel, iron nitrate, cobalt nitrate, nickel nitrate, nickel acetate and cobalt acetate; preferably, the reagents used to adjust the pH of the solution are hydrochloric acid solution, nitric acid solution, sulfuric acid solution, sodium hydroxide solution, Any one or more of potassium hydroxide solution and ammonia solution.

[0030] (2) Continue to stir and heat the mixed solution to any temperature of 50-150°C, and con...

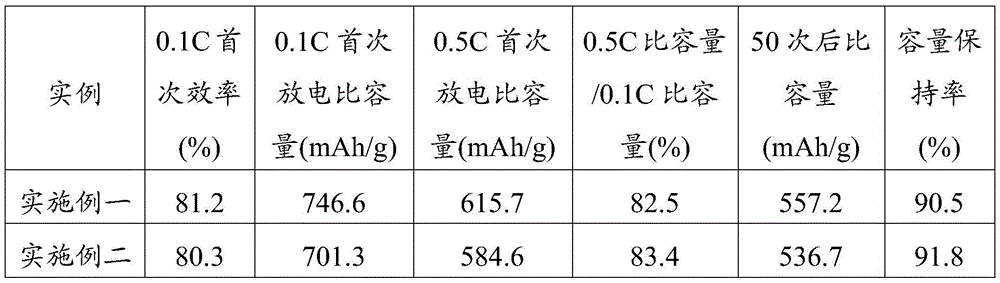

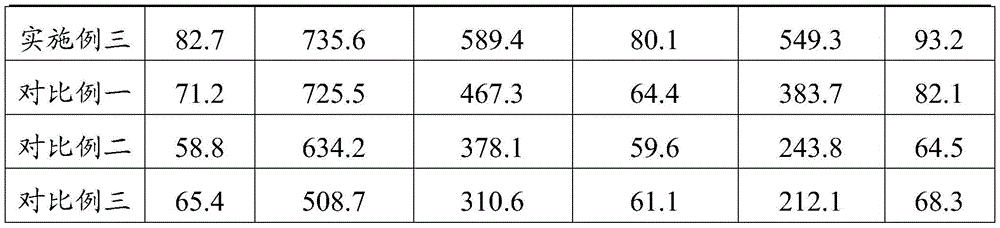

Embodiment 1

[0038] (1) Take the average particle size (D50) of 0.8μm silicon oxide (SiO x , X = 1.05) 100g, 18.7g urea, 16.8g ferric chloride hexahydrate, were added to 190g deionized water, and adjusted pH to 2 with 1mol / L HCl solution;

[0039] (2) Heat the mixed solution of step (1) to 90°C while stirring, keep constant temperature and continue stirring until no bubbles are generated during the stirring process, stop stirring, and then filter the resulting dark red suspension under reduced pressure, and then The filter cake was repeatedly washed several times and then vacuum dried at 100°C for 5 hours to obtain 106.3 g of precursor a;

[0040] (3) Dissolve 210 g of water citric acid in 600 g of deionized water, then add the precursor a, and then sequentially perform ultrasonic dispersion and centrifugal spray drying under continuous stirring to obtain the precursor b. The feed rate of centrifugal spray drying is 3.5kg / h, the spray inlet temperature is 250°C, the outlet temperature is 100°C,...

Embodiment 2

[0043] (1) Take silicon oxide (SiO) with an average particle size (D50) of 2.3 μm x , X=1.10) 100g, 18.6g urea, 15.1g cobalt chloride hexahydrate, respectively added to 220g deionized water, and adjusted pH to 2 with 1mol / L HCl solution.

[0044] (2) Heat the mixed solution of step (1) to 100°C while stirring, keep stirring at constant temperature and continue stirring until no bubbles are generated during the stirring process, stop stirring, and then filter the obtained dark blue suspension under reduced pressure, and then The filter cake was repeatedly washed several times and vacuum dried at 100°C for 5 hours to obtain 105.3 g of precursor a.

[0045] (3) Dissolve 20 g of pitch in 400 g of tetrahydrofuran, then add the precursor a, and then sequentially perform ultrasonic dispersion and centrifugal spray drying under continuous stirring to obtain the precursor b. The feed rate of centrifugal spray drying is 3.1kg / h, the spray inlet temperature is 160°C, the outlet temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com