Zinc-alkene anticorrosive paint for steel structure anti-corrosion

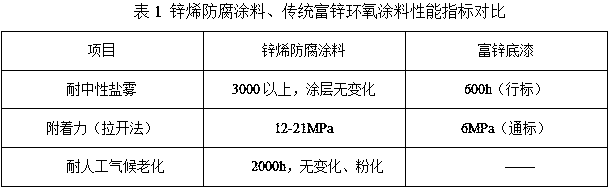

An anti-corrosion coating, zinc olefin technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problem of not being able to meet the requirements of use, achieve good physical shielding effect, improve corrosion resistance, and hinder the immersion of corrosive media Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

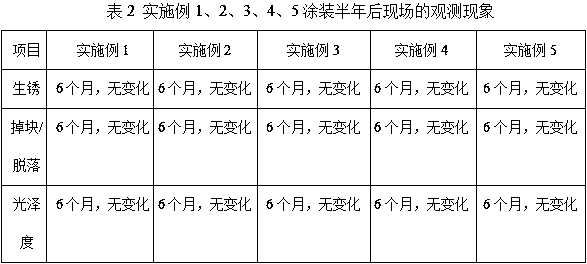

[0037] A kind of zinc ene anticorrosion paint, is made up of by weight ratio, modified epoxy resin 30%; Functional filler 30%; Zinc powder 15%, graphene 2%, surfactant 5%, xylene 8%, normal Butanol 10%.

[0038] In August 2016, using zinc olefin anti-corrosion coatings, in the Zhengzhou Bridge section of Zhengzhou Railway Bureau, the Longhai Main Line crossed Chengdong Road in Zhengzhou City and the sidewalk steel brackets of the Zijingshan Road Super Bridge to conduct on-site brushing tests. The bridge is located on Longhai downlink bus line K563+989~K565+084, with a total length of 1095m. On-site personnel carry out on-site brushing according to the usage method of the coating, and the specific construction process is the same as that of Example 1. This time, a total of 4 steel brackets were painted with 2kg of zinc olefin anti-corrosion paint.

Embodiment 2

[0040] A kind of zinc ene anticorrosion paint, is made up of by weight ratio, modified epoxy resin 35%; Functional filler 25%; Zinc powder 12%, graphene 2.5%, surfactant 3%, xylene 12.5%, normal Butanol 10%.

[0041] In August of the same year, zincene anti-corrosion coatings were used to carry out field brushing tests in the Xinxiang Bridge Section of Zhengzhou Railway Bureau and on the under-supported steel truss girders of the Beijing-Guangzhou Main Line across the Weihe Bridge. The bridge is located in the direction of heavy vehicles on the Beijing-Guangzhou line, with a central mileage of K597+177. The on-site staff brushed according to the usage method of the paint, and the specific construction process was the same as that of Example 1. This time, a total of 5.5 square meters and a steel bracket were painted with 1.5kg of zinc olefin anti-corrosion paint.

Embodiment 3

[0043] Modified epoxy resin 33.8%; functional filler 22%; zinc powder 20%, graphene 1.4%, surfactant 6%, xylene 6%, n-butanol 10.8%.

[0044] In September 2016, using zinc olefin anti-corrosion coatings, in the Zhengzhou Bridge section of Zhengzhou Railway Bureau, the Longhai Main Line crossed Chengdong Road in Zhengzhou City and the sidewalk steel brackets of the Zijingshan Road Super Bridge to conduct field brushing tests. The bridge is located on Longhai downlink bus line K563+989~K565+084, with a total length of 1095m. On-site personnel carry out on-site brushing according to the usage method of the coating, and the specific construction process is the same as that of Example 1. This time, a total of 8 steel brackets were painted with 4kg of zinc olefin anti-corrosion paint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com