Organic substance bonding-type zinc powder and preparation method thereof

A bonding type, organic technology, applied in dyeing low-molecular-weight organic compound treatment, anti-corrosion coatings, metal-free paints, etc., can solve the problems of coating corrosion damage, poor coating rust prevention, etc., and achieve low production cost , good economic and social benefits, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Raw material composition and mass number:

[0031] 12 kg of spherical zinc powder, 5 kg of triethanolamine, and 20 kg of water.

[0032] Preparation:

[0033] Add water into the stainless steel reaction kettle, start the stirring device, then add triethanolamine, fully dissolve at room temperature, and obtain triethanolamine aqueous solution. Then add the spherical zinc powder into the stainless steel reaction kettle, mix it evenly with the triethanolamine aqueous solution, react at 45°C for 30 minutes, then filter, wash the organically reacted zinc powder to neutrality, dry it, and crush it through an 80-mesh sieve , to obtain organic bonded zinc powder.

Embodiment 2

[0035] Raw material composition and mass number:

[0036] 10 kg of spherical zinc powder, 3 kg of triethanolamine, and 10 kg of water.

[0037] Preparation:

[0038] Add water into the stainless steel reaction kettle, start the stirring device, then add triethanolamine, fully dissolve at room temperature of 25°C, and obtain triethanolamine aqueous solution. Then add the spherical zinc powder into the stainless steel reaction kettle, mix it with triethanolamine aqueous solution evenly, react at room temperature of 25°C for 40 minutes, then filter, and wash the organically reacted zinc powder to neutrality, dry it, and crush it through 80 mesh Sieve to obtain organic bonded modified zinc powder.

Embodiment 3

[0040] Raw material composition and mass number:

[0041] 11 kg of spherical zinc powder, 4 kg of diethanolamine, and 12 kg of water.

[0042] Preparation:

[0043] Add water into the stainless steel reaction kettle, start the stirring device, then add diethanolamine, fully dissolve at room temperature of 30°C, and obtain an aqueous solution of diethanolamine. Then put the spherical zinc powder into the stainless steel reaction kettle, mix evenly with the diethanolamine aqueous solution, react at room temperature of 30°C for 30 minutes, then filter, and wash the organically reacted zinc powder to neutrality, dry it, and crush it through 80 mesh Sieve to obtain organic bonded zinc powder.

[0044] product result

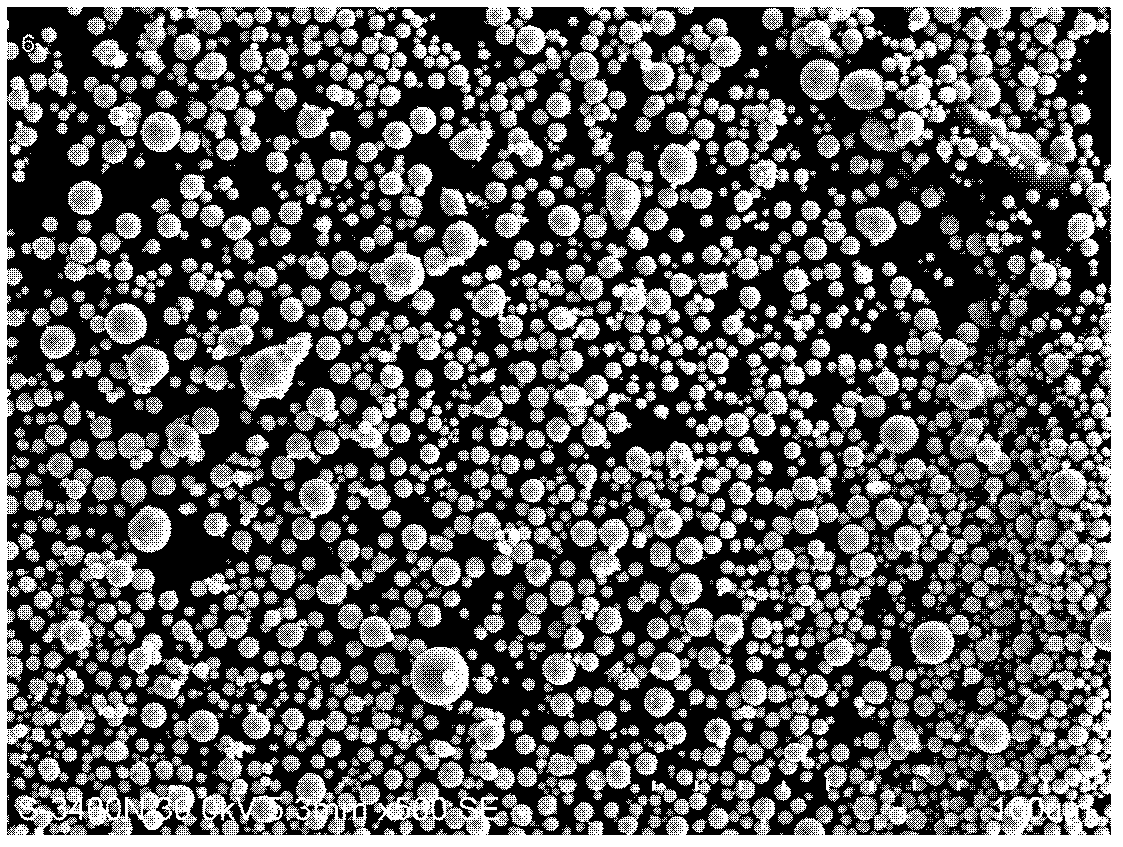

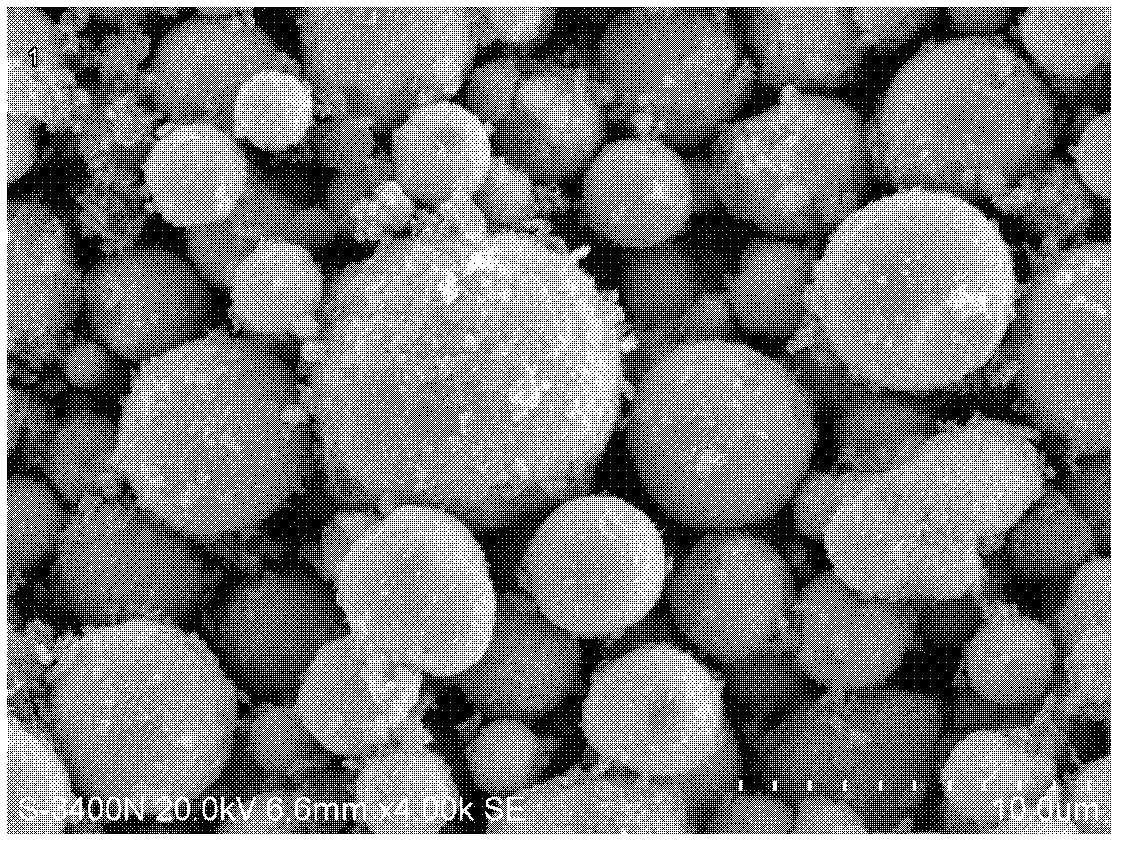

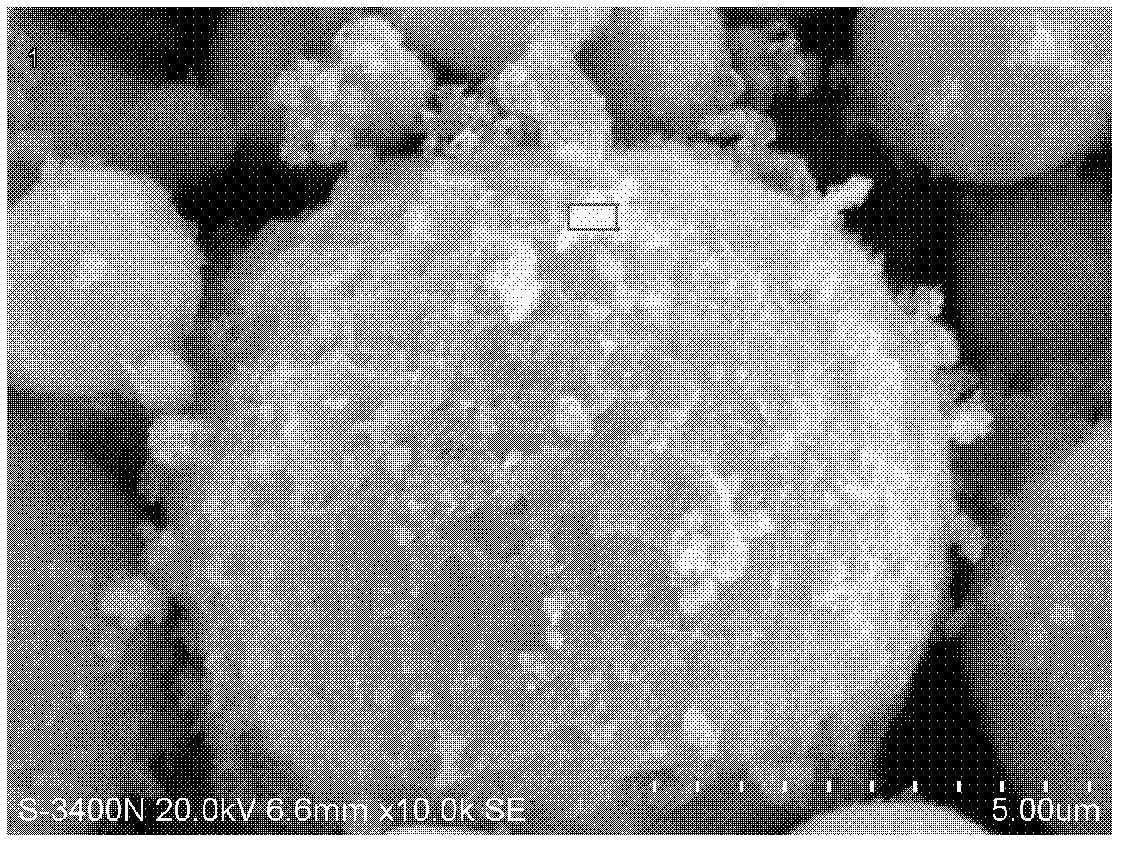

[0045] The SEM image of the surface treated zinc powder is shown in figure 2 , it can be seen that flake-like particles grow on the original spherical particles. The energy spectrum (EDS) observation results of the flake-like particles are shown in image 3 , is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com