Environment-friendly elastomer modified asphalt waterproof material and preparation method thereof

A technology of asphalt waterproof material and body modification, which is applied in building thermal insulation materials, building components, buildings, etc., can solve the problems such as the ineffective effect of asphalt thermal oxidation aging performance and the weakening of energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

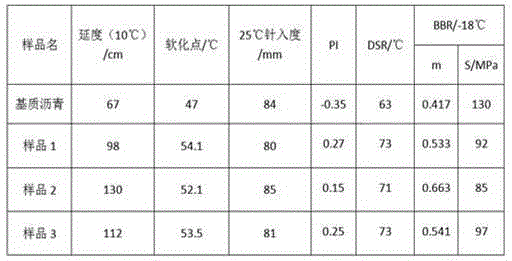

Embodiment 1

[0019] An environment-friendly elastomer modified asphalt waterproof material is composed of the following components by weight, 20 parts of 10# asphalt, 40 parts of 100# asphalt, 12 parts of elastomer modifier, layered double hydroxyl composite metal hydroxide 10 parts, 17 parts of talcum powder, 5 parts of stabilizer and 5 parts of filler; the softening point of the pitch is 45-50°C, and the elastomer modifier is linear styrene-butadiene - Styrene triblock thermoplastic elastomer, star-shaped styrene-butadiene-styrene triblock thermoplastic elastomer, or a mixture of two of them, mixed in any proportion, the layered double Preparation of hydroxyl complex metal hydroxide: Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O into Mg 2+ / Al 3+ A mixed brine solution with a molar ratio of 2:1, where [Mg 2+]=1mol / L, and adjust the pH value of the mixed salt solution to 10 with 2mol / L NaOH solution; take 400mL of the mixed salt solution, put it into a three-necked flask, condense and r...

Embodiment 2

[0029] An environment-friendly elastomer modified asphalt waterproof material is composed of the following components by weight, 30 parts of 10# asphalt, 50 parts of 100# asphalt, 15 parts of elastomer modifier, layered double hydroxyl composite metal hydroxide 15 parts of talcum powder, 10 parts of stabilizer and 10 parts of filler; the softening point of the pitch is 45-50°C, and the elastomer modifier is linear styrene-butadiene - Styrene triblock thermoplastic elastomer, star-shaped styrene-butadiene-styrene triblock thermoplastic elastomer, or a mixture of two of them, mixed in any proportion, the layered double Preparation of hydroxyl complex metal hydroxide: Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O into Mg 2+ / Al 3+ A mixed brine solution with a molar ratio of 2:1, where [Mg 2+ ]=1mol / L, and adjust the pH value of the mixed salt solution to 10 with 2mol / L NaOH solution; take 400mL of the mixed salt solution, put it into a three-necked flask, condense and reflux i...

Embodiment 3

[0039] An environment-friendly elastomer modified asphalt waterproof material is composed of the following components by weight, 30 parts of 10# asphalt, 50 parts of 100# asphalt, 15 parts of elastomer modifier, layered double hydroxyl composite metal hydroxide 15 parts of talc, 25 parts of talc, 10 parts of stabilizer and 10 parts of filler; the softening point of the asphalt is 45-50°C, and the modifying agent is composed of inorganic filler, polymer, stabilizer and coupler The composition of the joint agent; the inorganic filler is montmorillonite, calcium carbonate or fly ash, or a mixture of them in any weight ratio, and the particle diameter is 0.04-20 μm; the polymer is a star-shaped thermoplastic elastomer polystyrene- Butadiene-styrene, wherein the content of styrene is 20% to 30% by weight; the stabilizer is PN-2 type, SWD type or HMD type stabilizer, or a mixture of them in any weight ratio; the coupling agent is Silane coupling agent, titanate coupling agent or alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com