Graphene super anticorrosive powdery paint, and preparation method thereof

A powder coating and graphene technology, applied in powder coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of polluting the environment, containing harmful and toxic solvents, etc., and achieve high cross-linking density, good physical shielding effect, and weather resistance good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

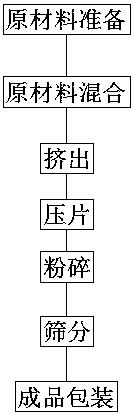

[0044] Produce a kind of graphene ultra-corrosion powder coating, its concrete steps are as follows:

[0045] a. Weigh the raw materials and prepare the following raw materials in parts by mass:

[0046] Polyphenol type glycidyl ether epoxy resin 35kg;

[0047] Hydantoin epoxy resin 25kg;

[0048] Graphene particles 10kg;

[0049] Glass beads 15kg;

[0050] 2-methylimidazole 2kg;

[0051] Mica powder 8kg;

[0052] Leveling agent 2kg;

[0053] Iron red 5kg;

[0054] Benzoin 0.5kg;

[0055] b. Add the raw materials prepared in step a into the Misekra cylinder of the mixer for pre-mixing. The mixing time is: 2 minutes at low speed and 6 minutes at high speed; the speed at low speed is 110r / min, and the speed at high speed is 320r / min;

[0056] c. Putting the homogeneously mixed material in step b into an ultrasonic extruder for extruding;

[0057] d, sending the mixture extruded by the extruder in step c into a tablet press for tableting, cooling and crushing to obtain a...

Embodiment 2

[0062] Produce a kind of graphene ultra-corrosion powder coating, its concrete steps are as follows:

[0063] a. Weigh the raw materials and prepare the following raw materials in parts by mass:

[0064] Polyphenol type glycidyl ether epoxy resin 41.2kg;

[0065] Hein epoxy resin 28.8kg;

[0066] Graphene particles 11.5kg;

[0067] Glass beads 16kg;

[0068] 2-methylimidazole 2.4kg;

[0069] Mica powder 9kg;

[0070] Leveling agent 2kg;

[0071] Iron red 6.7kg;

[0072] Benzoin 0.5kg;

[0073] b. Add the raw materials prepared in step a into the Misekra cylinder of the mixer for pre-mixing. The mixing time is: 2 minutes at low speed and 6 minutes at high speed; the speed at low speed is 110r / min, and the speed at high speed is 320r / min;

[0074] c. Putting the homogeneously mixed material in step b into an ultrasonic extruder for extruding;

[0075] d, sending the mixture extruded by the extruder in step c into a tablet press for tableting, cooling and crushing to obt...

Embodiment 3

[0080] Produce a kind of graphene ultra-corrosion powder coating, its concrete steps are as follows:

[0081] a. Weigh the raw materials and prepare the following raw materials in parts by mass:

[0082] Polyphenol type glycidyl ether epoxy resin 45kg;

[0083] Hydantoin epoxy resin 35kg;

[0084] Graphene particles 12kg;

[0085] Glass beads 18kg;

[0086] 2-Methylimidazole 3kg;

[0087] Mica powder 10kg;

[0088] Leveling agent 2kg;

[0089] Iron red 8kg;

[0090] Benzoin 0.5kg;

[0091] b. Add the raw materials prepared in step a into the Misekra cylinder of the mixer for pre-mixing. The mixing time is: 2 minutes at low speed and 6 minutes at high speed; the speed at low speed is 110r / min, and the speed at high speed is 320r / min;

[0092] c. Putting the homogeneously mixed material in step b into an ultrasonic extruder for extruding;

[0093] d, sending the mixture extruded by the extruder in step c into a tablet press for tableting, cooling and crushing to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com