Graphene modified pure polyester powdery coating and preparation method thereof

A graphene modification, polyester powder technology, applied in powder coatings, polyester coatings, anti-corrosion coatings, etc., can solve the deterioration of weather resistance and anti-corrosion performance, increase the use and maintenance costs of coatings, shorten the service life of workpieces, etc. problems, to achieve the effect of improving adhesion, good physical shielding effect, and increasing resistance to neutral salt spray time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

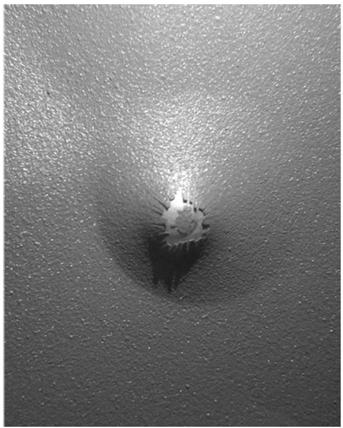

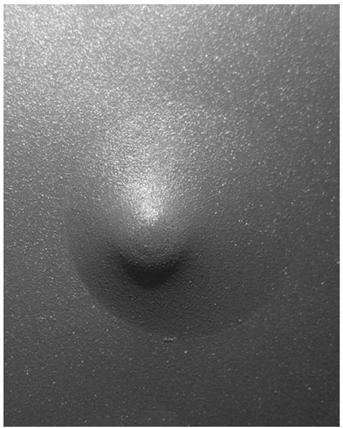

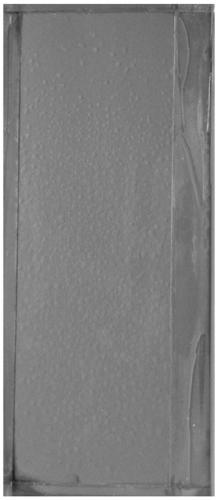

Image

Examples

Embodiment 1

[0035] A graphene modified pure polyester powder coating, comprising 62 parts by weight of matrix resin, 4 parts by weight of curing agent, 31 parts by weight of pigments and fillers, 0.3 parts by weight of degassing agent, 0.5 parts by weight of leveling agent, The antioxidant of 0.2 weight part and the graphene of 2 weight parts. Among them, the matrix resin is hydroxyl polyester resin, the type of curing agent is TGIC, the pigment and filler is a combination of carbon black, calcium carbonate and barium sulfate, the degassing agent is benzoin, the type of leveling agent is PV88, and the type of antioxidant It is antioxidant 1010.

[0036] The preparation method of this graphene modified pure polyester powder coating comprises the steps:

[0037] (1) 62 parts by weight of the matrix resin and the graphene of 2 parts by weight are mixed, put into a high-speed stirring pulverizer, stir and pulverize 2min with the speed of 20000rpm, obtain the blend of graphene and matrix resi...

Embodiment 2

[0040] A graphene modified pure polyester powder coating, comprising 57 parts by weight of matrix resin, 3.5 parts by weight of curing agent, 37 parts by weight of pigments and fillers, 0.3 parts by weight of degassing agent, 0.5 parts by weight of leveling agent , the antioxidant of 0.2 weight part and the graphene of 1.5 weight part. Among them, the matrix resin is hydroxyl polyester resin, the type of curing agent is TGIC, the pigment and filler is a combination of titanium dioxide, calcium carbonate and barium sulfate, the degassing agent is benzoin, the type of leveling agent is GLP503, and the type of antioxidant for PEP-36.

[0041] The preparation method of this graphene modified pure polyester powder coating comprises the steps:

[0042] (1) The matrix resin of 57 parts by weight is mixed with the graphene of 1.5 parts by weight, put into a high-speed stirring pulverizer, stir and pulverize 2min with the speed of 20000rpm, obtain the blend of graphene and matrix resi...

Embodiment 3

[0045] A graphene modified pure polyester powder coating, comprising 49 parts by weight of matrix resin, 3.5 parts by weight of curing agent, 46 parts by weight of pigments and fillers, 0.3 parts by weight of degassing agent, 0.5 parts by weight of leveling agent, The antioxidant of 0.2 weight part and the graphene of 1 weight part, wherein, matrix resin is hydroxyl polyester resin, and the model of curing agent is Primid XL-522, and pigment filler is the combination of carbon black, calcium carbonate and barium sulfate, removes The air agent is benzoin, the model of leveling agent is GLP588, and the model of antioxidant is antioxidant 1010.

[0046] The preparation method of this graphene modified pure polyester powder coating comprises the steps:

[0047] (1) The matrix resin of 49 parts by weight and the graphene of 1 weight part are mixed, put into the high-speed stirring pulverizer, stir and pulverize 2min with the speed of 20000rpm, obtain the blend of graphene and matri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com