Ultraviolet-resistant bituminous pavement crack filling glue and preparation method thereof

A technology of asphalt pavement and joint glue, which is applied in the direction of asphalt material adhesive, adhesive, adhesive type, etc., can solve the problems of high price of finished joint glue, high price of SBS, brittle failure of joint glue, etc. Achieve the effect of improving anti-ultraviolet aging ability, improving low-temperature deformation ability, and preventing low-temperature brittle fracture

Active Publication Date: 2016-02-17

甘肃恒石公路检测科技有限公司

View PDF2 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] (1) During the on-site use of the joint glue, especially in the high-altitude and strong ultraviolet areas in the west, the aromatic components in the asphalt component are easily aged by ultraviolet light, which makes the joint glue harden as a whole, and the joint glue i

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

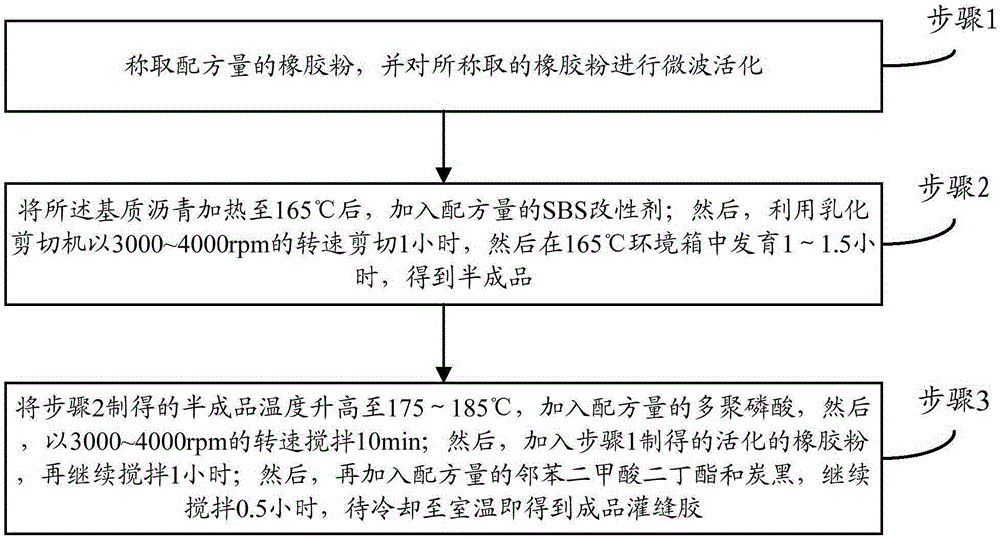

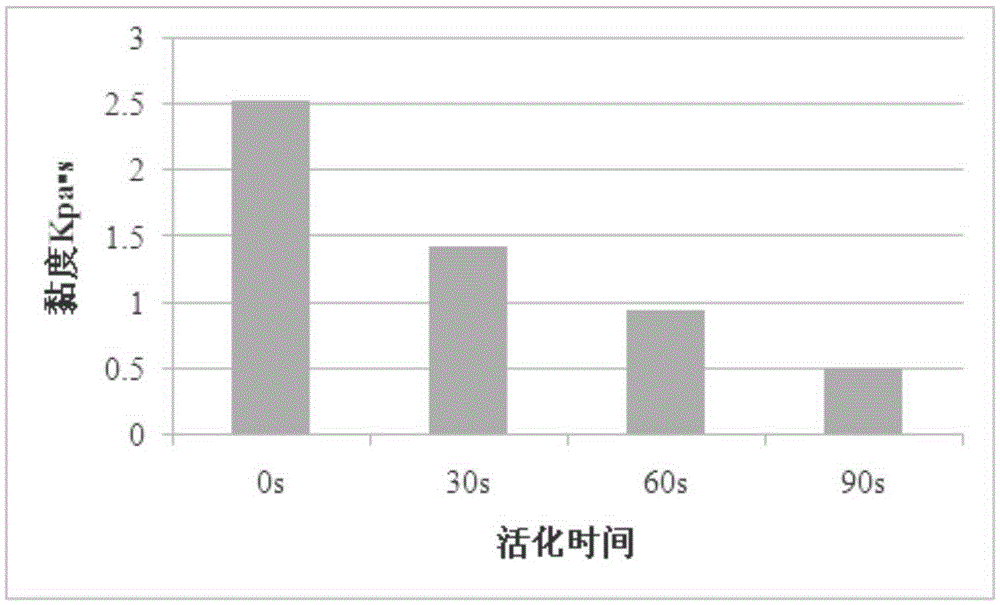

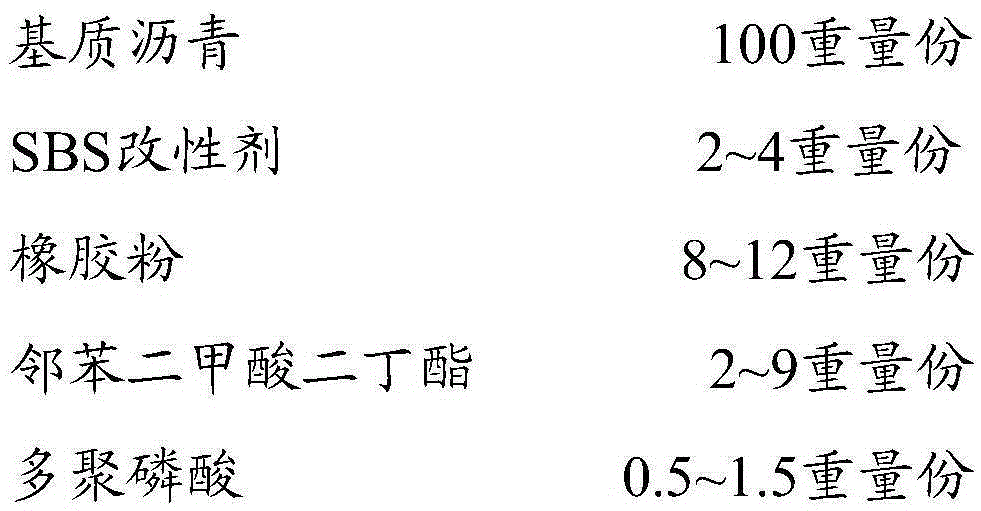

The invention provides ultraviolet-resistant bituminous pavement crack filling glue and a preparation method thereof. The crack filling glue is prepared from, by weight, 100 parts of matrix asphalt, 2-4 parts of SBS modifier, 8-12 parts of rubber powder, 2-9 parts of dibutyl phthalate, 0.5-1.5 parts of polyphosphoric acid and 1-3 parts of carbon black. The ultraviolet-resistant bituminous pavement crack filling glue has the advantages that polyphosphoric acid is used for replacing part of traditional SBS, and due to the fact that the price of polyphosphoric acid is far lower than that of SBS, on the premise that the high temperature performance of the crack filling crack is kept unchanged or is slightly improved, the cost of the crack filling glue is effectively reduced; the carbon black capable of absorbing ultraviolet rays is added to the crack filling glue, the ultraviolet aging resisting capacity of the crack filling glue can be effectively improved, and the stability of the crack filling glue can be improved; the adopted rubber powder is rubber powder obtained after microwave activation, the viscosity of the prepared crack filling glue is reduced, the low temperature deformation capacity of the crack filling glue is improved, and the crack filling glue is prevented from low temperature brittle failure.

Description

technical field [0001] The invention belongs to the technical field of asphalt pavement maintenance, and in particular relates to an ultraviolet-resistant asphalt pavement crack filling glue and a preparation method thereof. Background technique [0002] Pavement cracks are the most common form of road damage, and injecting joint glue into pavement cracks is the most practical way to treat pavement cracks. [0003] At present, there are many kinds of asphalt-based joint-filling adhesives on the market, some of which are tested according to the existing "Pavement Rubber Asphalt Joint-filling Adhesive" (JT / T740-2009), and the other part is based on asphalt Material performance index testing. [0004] However, the inventor found in the process of realizing the present invention that the existing caulking glue has at least the following problems: [0005] (1) During the on-site use of the joint glue, especially in the high-altitude and strong ultraviolet areas in the west, the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J195/00C09J11/08C09J11/06C09J11/04

CPCC08L2201/08C08L2205/03C09J11/04C09J11/06C09J11/08C09J195/00C08L53/02C08L21/00C08K5/12C08K2003/329C08K3/04

Inventor 马伟中李波李艳博李杰颜鲁春

Owner 甘肃恒石公路检测科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com