Oil enhanced fog seal material for asphalt pavement and preparation method and construction method of oil enhanced fog seal material

A technology of fog seal layer material and asphalt pavement, which is applied in building insulation materials, roads, roads, etc., and can solve the problem that the adhesion between the original fog seal layer and the original pavement stone material cannot achieve the expected effect and reduce the anti-skid ability of the asphalt pavement surface layer , the reduction of the anti-seepage capacity of the pavement, etc., to achieve the effect of improving the anti-seepage capacity of the pavement, delaying ultraviolet aging, and improving the firmness of the pavement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

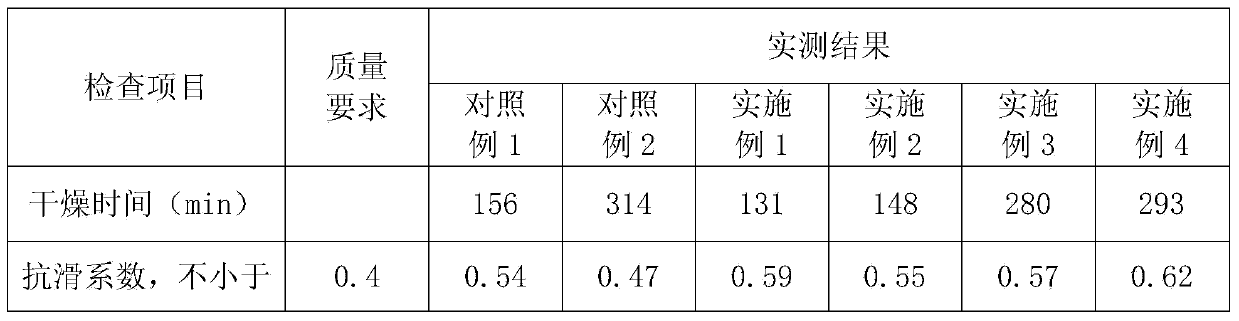

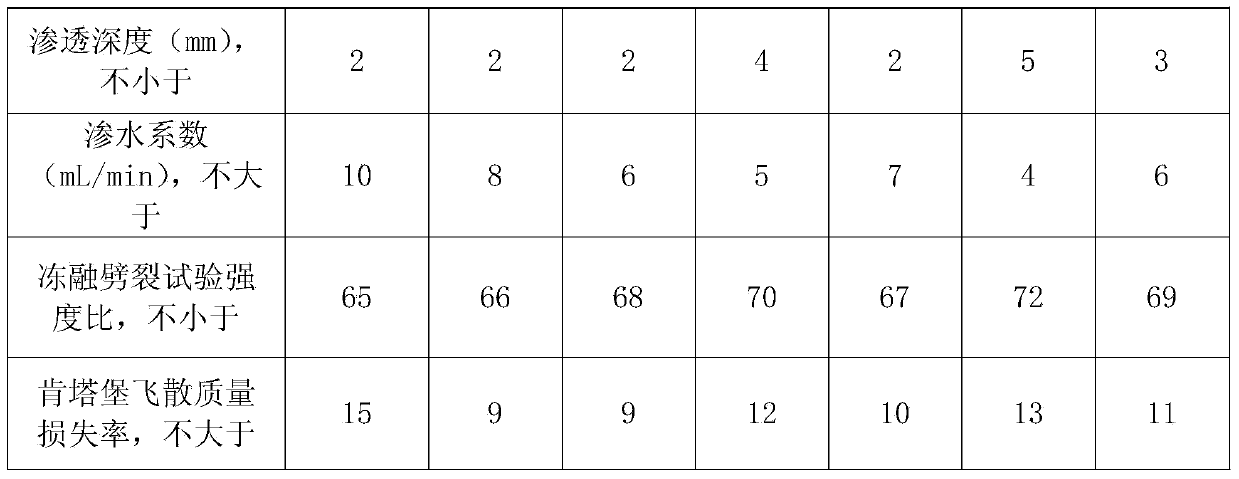

Examples

Embodiment 1

[0056] Take the preparation of an oily enhanced fog seal material for asphalt pavement as an example for illustration.

[0057] (1) Weigh each component:

[0058] The sub-layer emulsion material for waterproof penetration includes the following components in parts by weight: 50 parts of 90# asphalt, 20 parts of D-80 kerosene solvent oil, 1 part of Lei Fengnuo, 2 parts of modified latex, and 2 parts of styrene butadiene particles.

[0059] The anti-slip and wear-resistant upper sub-layer emulsion material includes the following components in parts by weight: 50 parts of 90# asphalt, 20 parts of D-80 kerosene solvent oil, 1 part of Lei Fengnuo, 5 parts of modified latex, and 2 parts of styrene butadiene particles , 2 parts of phenyl salicylate.

[0060] (2) The preparation method of oily mist seal layer emulsion material:

[0061] The preparation method of the waterproof permeable lower sub-layer emulsion material: first heat and melt the petroleum asphalt, then mix it with so...

Embodiment 2

[0070] Take the preparation of an oily enhanced fog seal material for asphalt pavement as an example for illustration.

[0071] (1) Weigh each component:

[0072] The sub-layer emulsion material for waterproof penetration includes the following components in parts by weight: 70 parts of 70# asphalt, 60 parts of S-100 kerosene solvent oil, 10 parts of Lei Fengnuo, 8 parts of silane coupling agent KH7928, and 8 parts of modified rubber powder.

[0073] The anti-slip and wear-resistant upper sub-layer emulsion material includes the following components in parts by weight: 70 parts of 70# asphalt, 60 parts of S-100 kerosene solvent oil, 10 parts of Lei Fengnuo, silane coupling agent KH7928 parts, 4 parts of modified rubber powder, Benzophenone - 31 parts.

[0074] (2) The preparation method of oily mist seal layer emulsion material:

[0075] The preparation method of the waterproof permeable lower sub-layer emulsion material: first heat and melt the petroleum asphalt, then mix i...

Embodiment 3

[0084] Take the preparation of an oily enhanced fog seal material for asphalt pavement as an example for illustration.

[0085] (1) Weigh each component:

[0086] The sub-layer emulsion material for waterproof penetration includes the following components in parts by weight: 60 parts of 90# asphalt, 40 parts of S-100 solvent oil, 8 parts of Lei Fengnuo, 10 parts of silane coupling agent KH5500, and 6 parts of rock asphalt.

[0087] The anti-slip and wear-resistant upper sub-layer emulsion material includes the following components in parts by weight: 60 parts of 90# asphalt, 40 parts of S-100 solvent oil, 5 parts of Lei Feng Nuo, 15 parts of silane coupling agent KH55015, 3 parts of rock asphalt, salicylic acid 2 parts of phenyl ester.

[0088] (2) The preparation method of oily mist seal layer emulsion material:

[0089] The preparation method of the waterproof permeable lower sub-layer emulsion material: first heat and melt the petroleum asphalt, then mix it with solvent o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com