Application of xylose residue in preparation of wood plastic material

A technology of wood-plastic materials and xylose slag, applied in the field of composite materials, can solve the problem of insufficient utilization of xylose slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

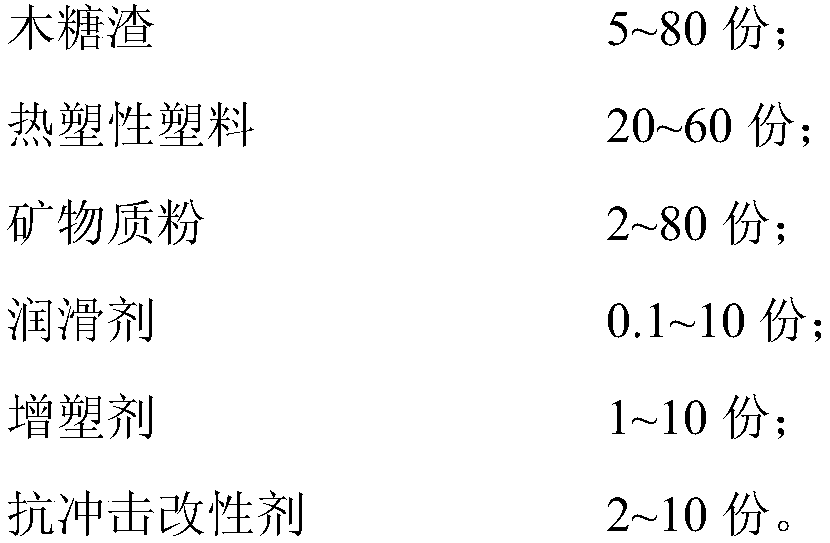

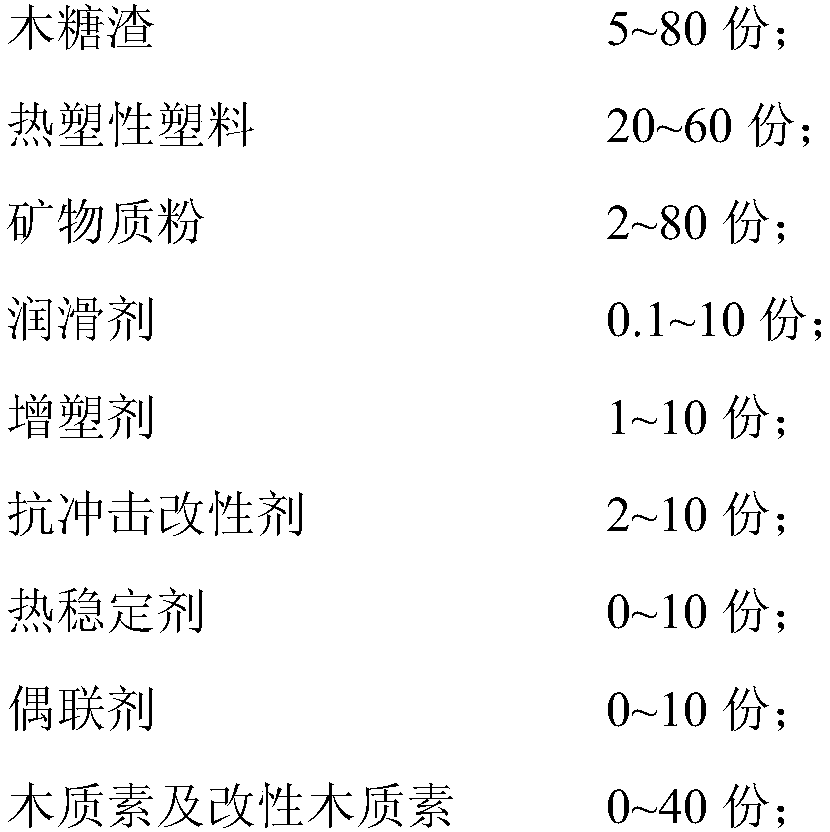

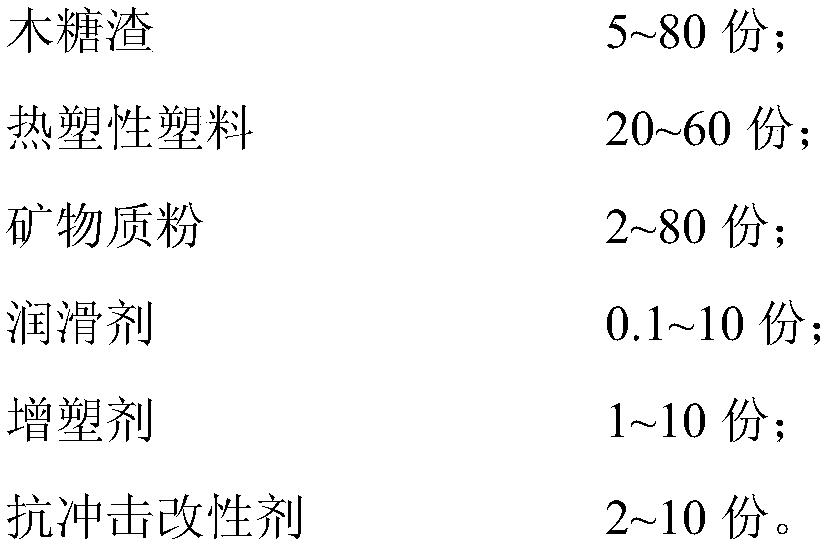

Method used

Image

Examples

Embodiment 1

[0096] Raw materials: 20 parts of dried xylose residue (300 mesh), 50 parts of polyethylene, 25 parts of nanometer calcium carbonate, 0.7 part of calcium stearate, 0.8 part of polyethylene wax, 2 parts of dioctyl phthalate, 8 acrylate copolymer.

[0097] The manufacturing method includes the following processes:

[0098] (1) Mix raw materials. Mixing is divided into two stages: hot mixing and cold mixing. First, heat mixing. According to the proportion, add each raw material to a high-speed mixer and mix at high speed (800rpm) until the temperature reaches 120°C, and then mix at a low speed (200rpm). When the temperature is lower than 90°C, the material is discharged;

[0099] (2) Make raw material granules, put the mixed raw materials into a twin-screw extrusion granulator for granulation;

[0100] (3) Extrude the profile, add the prepared raw material pellets into the single-screw extruder, and a mold with a specific shape is installed at the outlet of the screw mouth. The...

Embodiment 2

[0102] Raw materials: 15 parts of dried xylose residue (80 mesh), 3 parts of enzymatic lignin, 50 parts of polyethylene, 25 parts of glass fiber, 0.5 part of calcium stearate, 0.7 part of liquid paraffin, 5 parts of phthalic acid Dioctyl ester, 6 parts chlorinated polyethylene CPE

[0103] The manufacturing method includes the following processes:

[0104] (1) Mix raw materials. Mixing is divided into two stages: hot mixing and cold mixing. First, heat mixing. According to the proportion, add each raw material to a high-speed mixer and mix at high speed (800rpm) until the temperature reaches 120°C, and then mix at a low speed (200rpm). When the temperature is lower than 90°C, the material is discharged;

[0105] (2) Extrude the profile, add the mixed material into the parallel twin-screw extruder, and a mold with a specific shape is installed at the outlet of the screw mouth. The material is in a molten state under high temperature and high pressure, and enters from the entra...

Embodiment 3

[0107] Raw materials: 55 parts of dried xylose residue (100 mesh), 5 parts of lignosulfonate, 60 parts of polypropylene, 30 parts of asbestos fiber, 2 parts of zinc stearate, 3 parts of polyethylene wax, 10 parts of Malay Anhydride grafted polypropylene, 3 parts chlorinated paraffin, 2 parts ethylene-vinyl acetate copolymer

[0108] The manufacturing method includes the following processes:

[0109] (1) Mix raw materials. Mixing is divided into two stages: hot mixing and cold mixing. First, heat mixing. According to the proportion, add each raw material to a high-speed mixer and mix at high speed (800rpm) until the temperature reaches 120°C, and then mix at a low speed (200rpm). When the temperature is lower than 90°C, the material is discharged;

[0110] (2) Extrude the profile, add the mixed material into the conical twin-screw extruder, and a mold with a specific shape is installed at the outlet of the screw mouth. The material is in a molten state under high temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com