Water-based wood coating with antibacterial, anti-fouling, mosquito-repellent and insect-repellent effects, and preparation method thereof

A wood coating, water-based technology, applied in the field of coatings, can solve the problems of coating film water resistance, poor chemical resistance, low hardness, hot stickiness and cold brittleness, etc., achieve good compatibility, good flame retardancy, and promote separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

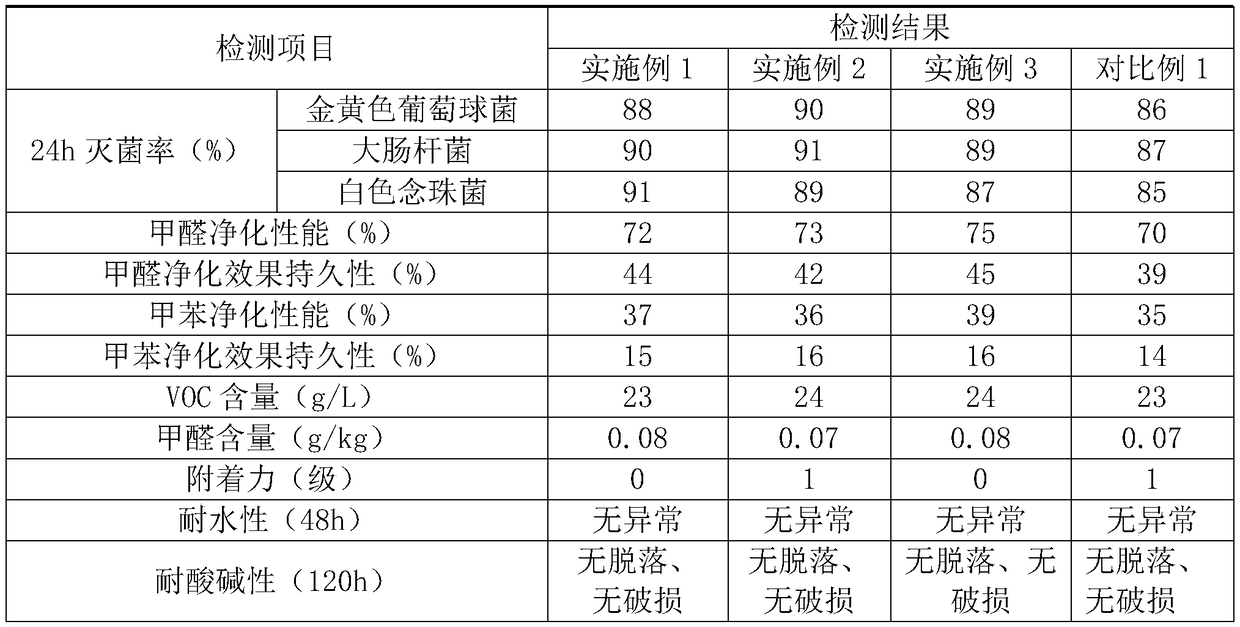

Examples

Embodiment 1

[0043]In the present embodiment, the antibacterial and antifouling, anti-mosquito and anti-insect water-based wood coatings are obtained by the following preparation process:

[0044] (1) Preparation of water-based composite emulsion: Mix 25 parts of water-based polyacrylate and 0.6 part of cosolvent, stir, then add 7 parts of water-based polyurethane, 1.5 parts of water-based fluorocarbon resin, 2 parts of natural plant essential oil, 3 parts of deionized water, 2 parts of wood wax oil and 1 part of silicone oil are stirred evenly to obtain a water-based composite emulsion;

[0045] In this embodiment, the co-solvent includes 0.1 part of alkanolamine and 0.5 part of ammonia water; the natural plant essential oil includes 1 part of eucalyptus oil and 1 part of litsea cubeba oil; the silicone oil includes 0.5 part of methyl silicone oil and 0.5 part of ethyl silicone oil;

[0046] (2) Preparation of inorganic nanocomposite slurry: Mix 0.05 parts of surfactant with 1.2 parts of ...

Embodiment 2

[0055] In the present embodiment, the antibacterial and antifouling, anti-mosquito and anti-insect water-based wood coatings are obtained by the following preparation process:

[0056] (1) Preparation of water-based composite emulsion: Mix 24 parts of water-based polyacrylate and 0.5 part of cosolvent, stir, then add 10 parts of water-based polyurethane, 2.5 parts of water-based fluorocarbon resin, 4 parts of natural plant essential oil, 4 parts of deionized water, 3 parts of wood wax oil and 2 parts of silicone oil are stirred evenly to obtain a water-based composite emulsion;

[0057] In this embodiment, the co-solvent includes 0.2 parts of alkanolamine and 0.3 parts of ammonia water; the natural plant essential oil includes 2 parts of eucalyptus oil and 2 parts of camphor oil; the silicone oil includes 0.5 part of methyl silicone oil, 0.5 part of ethyl silicone oil, and 1 part of phenyl silicone oil ;

[0058] (2) Preparation of inorganic nanocomposite slurry: Mix 0.1 part...

Embodiment 3

[0067] In the present embodiment, the antibacterial and antifouling, anti-mosquito and anti-insect water-based wood coatings are obtained by the following preparation process:

[0068] (1) Preparation of water-based composite emulsion: Mix 30 parts of water-based polyacrylate and 0.8 parts of co-solvent, stir, then add 12 parts of water-based polyurethane, 2 parts of water-based fluorocarbon resin, 5 parts of natural plant essential oil, 6 parts of deionized water, 4 parts of wood wax oil and 2.5 parts of silicone oil are stirred evenly to obtain an aqueous composite emulsion;

[0069] In this embodiment, the co-solvent includes 0.3 parts of alkanolamine and 0.5 parts of ammonia water; natural plant essential oils include 2 parts of eucalyptus oil, 2 parts of camphor oil, and 1 part of litsea cubeba oil; silicone oil includes 1 part of ethyl silicone oil and 1 part of phenyl silicone oil. part, 0.5 part of methyl vinyl silicone oil;

[0070] (2) Preparation of inorganic nanoc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com