PVC (Polyvinyl Chloride)-lignin-sulfate wood-plastic composite material and preparation method thereof

A wood-plastic composite material and lignin technology, which is applied in the field of PVC-lignin-sulfate wood-plastic composite material and its preparation, can solve the problems of insufficient utilization of lignin and poor performance of wood-plastic materials, and achieve Effects of improving mechanical properties, improving toughness, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

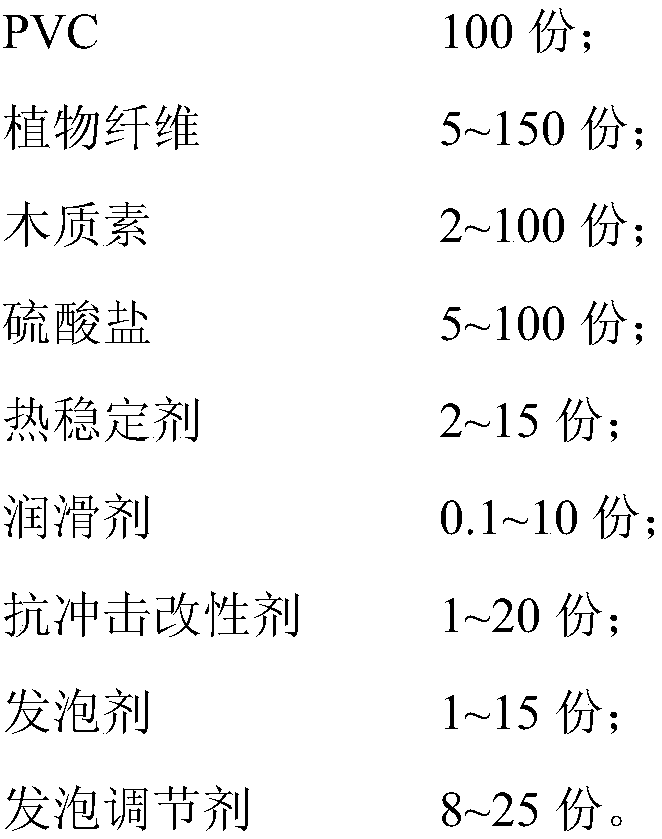

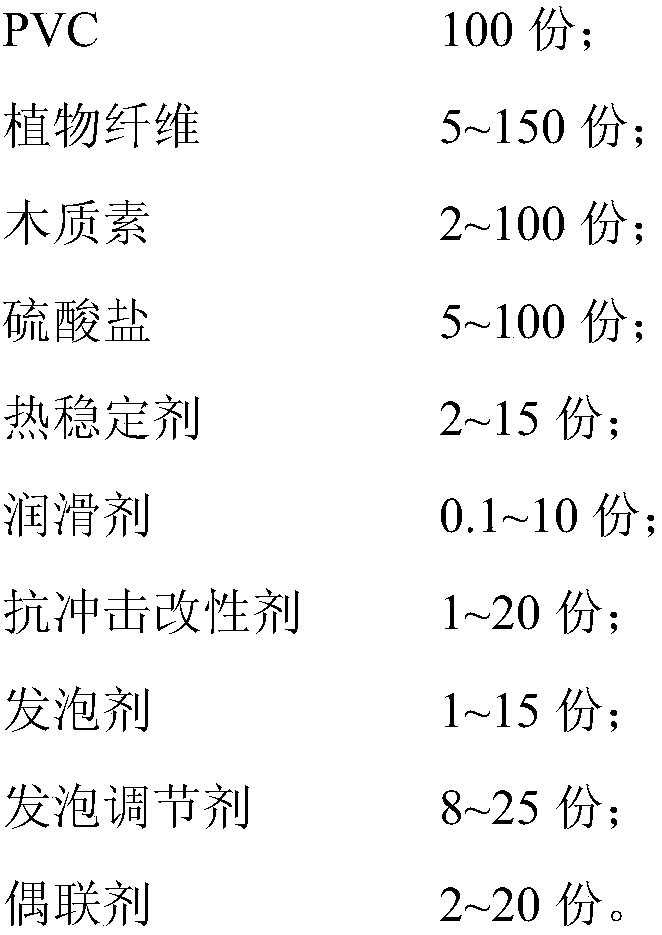

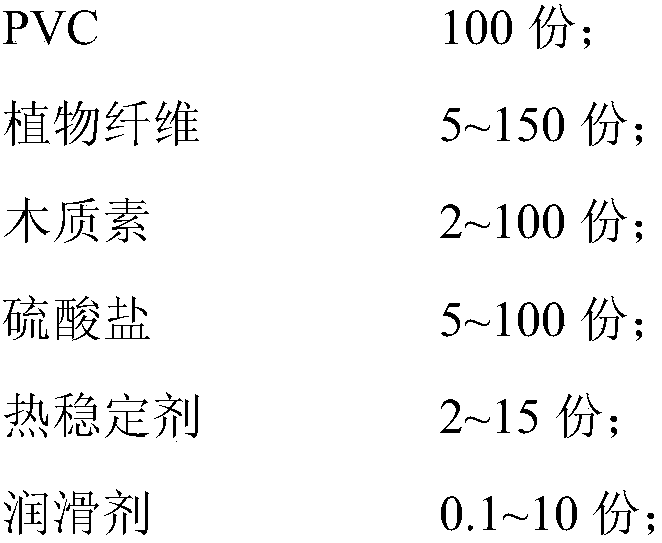

Method used

Image

Examples

Embodiment 1

[0055] Raw materials: 20 parts of dried wood flour, 100 parts of PVC, 25 parts of calcium sulfate whiskers, 20 parts of alkali lignin, 6 parts of composite calcium zinc stabilizer, 0.7 parts of calcium stearate, 0.8 parts of polyethylene wax, 2 parts Dioctyl phthalate, 8 parts chlorinated polyethylene, 5 parts azodicarbonamide, 12 parts foam regulator

[0056] Manufacturing method process is the same as comparative example 1

Embodiment 2

[0058] Raw materials: 60 parts of dried corn stalk powder, 100 parts of PVC, 25 parts of anhydrous zinc sulfate, 80 parts of enzymatic lignin, 8 parts of composite lead stabilizer, 1 part of calcium stearate, 1.8 parts of polyethylene wax, 6 Dioctyl phthalate, 9 parts chlorinated polyethylene, 5 parts azodicarbonamide, 16 parts foam regulator

[0059] The manufacturing method includes the following processes:

[0060] (1) Mix raw materials. Mixing is divided into two stages: hot mixing and cold mixing. First, heat mixing. According to the proportion, add each raw material to a high-speed mixer and mix at high speed (800rpm) until the temperature reaches 120°C, and then mix at a low speed (200rpm). When the temperature is lower than 90°C, the material is discharged;

[0061] (2) Extrude the profile, add the mixed material into the conical twin-screw extruder, and a mold with a specific shape is installed at the outlet of the screw mouth. The material is in a molten state under...

Embodiment 3

[0063] Raw materials: 20 parts of dried bamboo powder, 100 parts of PVC, 20 parts of anhydrous magnesium sulfate, 100 parts of enzymatic lignin, 7 parts of organotin stabilizers, 1 part of polyol ester, 2 parts of polyethylene wax, 3 parts Petroleum ester, 9 parts of methacrylic acid-butadiene-styrene copolymer MBS, 5 parts of azodicarbonamide, 3 parts of sodium bicarbonate, 14 parts of foam regulator

[0064] Manufacturing method technology is the same as embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com