High-flame-retardant photoelectric composite cable sheath material with good processability and preparation method thereof

A technology for optoelectronic composite cables and sheathing materials, which is applied in the field of cable sheathing materials, can solve the problems of reduced processing performance and mechanical properties of composite materials, endangering life and property safety, poor processing flow performance and thermal stability of PVC resins, etc. Good processability and heat resistance, broad market application prospects, excellent low smoke characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

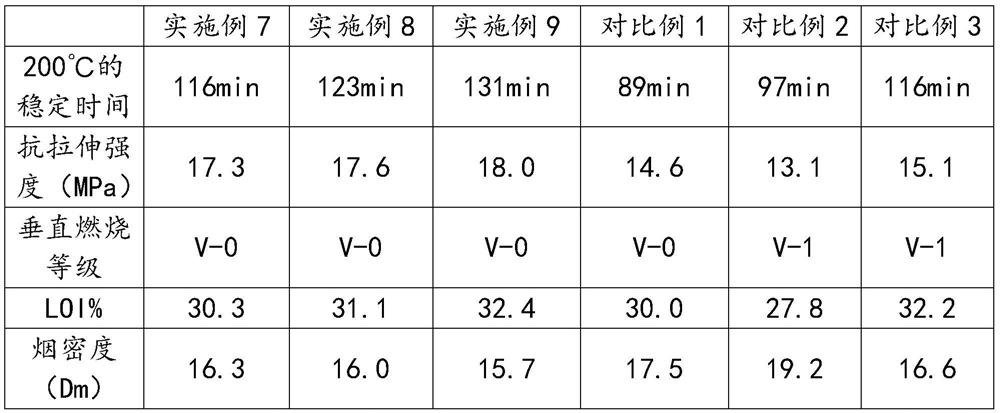

Examples

Embodiment 1

[0027] Preparation of modified glass fibers:

[0028] Heat-treat the glass fibers at 300°C for 2 hours, cool to room temperature, add deionized water, ultrasonicate for 20 minutes, then filter with suction and dry to obtain treated glass fibers, wherein the mass ratio of glass fibers to deionized water is 1: 10. Immerse the treated glass fiber in the aqueous solution of polydimethyldiallylammonium chloride at room temperature, stir at 300r / min for 30min, then suction filter, wash and dry to obtain wrapped glass fiber, wherein the treated glass fiber The solid solution ratio of the fiber and the aqueous solution of polydimethyldiallyl ammonium chloride is 5g:4L, the polydimethyldiallyl ammonium chloride in the aqueous solution of polydimethyldiallyl ammonium chloride The concentration is 2g / L; disperse the wrapped glass fiber in the ethanol solution of nano-silica, ultrasonically disperse it for 20 minutes, let it stand for 20 minutes, filter it with suction, wash it with water...

Embodiment 2

[0030] Preparation of modified glass fibers:

[0031] Heat-treat the glass fibers at 300°C for 2 hours, cool to room temperature, add deionized water, ultrasonicate for 30 minutes, then filter with suction and dry to obtain treated glass fibers, wherein the mass ratio of glass fibers to deionized water is 1: 10. Immerse the treated glass fiber in the aqueous solution of polydimethyldiallylammonium chloride at room temperature, stir at 500r / min for 20min, then suction filter, wash, and dry to obtain wrapped glass fiber, wherein the treated glass fiber The solid solution ratio of the fiber and the aqueous solution of polydimethyldiallyl ammonium chloride is 5g:5L, the polydimethyldiallyl ammonium chloride in the aqueous solution of polydimethyldiallylammonium chloride The concentration is 2g / L; disperse the wrapped glass fiber in the ethanol solution of nano-silica, ultrasonically disperse it for 30 minutes, let it stand for 30 minutes, filter it with suction, wash it with water...

Embodiment 3

[0033] Reactive silicon flame retardants are made through the following steps:

[0034]Add 19g of pentaerythritol methylsilicate and 9.5g of epichlorohydrin into a three-necked flask, then add 15g of anhydrous potassium carbonate and 100mL of toluene, stir, heat to 75°C, ring-opening reaction for 4 hours, add 4g of NaOH solid, and ring-closing reaction for 4 hours , after the reaction is finished, filter with suction, and the filtrate is rotary evaporated to obtain a reactive silicon flame retardant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com