Full-biodegradable plastic alloy and preparation method thereof

A technology of degrading plastics and biodegradation, applied in the field of plastic alloys, can solve the problems of poor fluidity of high-molecular-weight polymer raw materials, difficult dispersion of composite material components, and difficulty in ensuring alloy compatibility, etc., to achieve strong force and dispersion Uniform, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

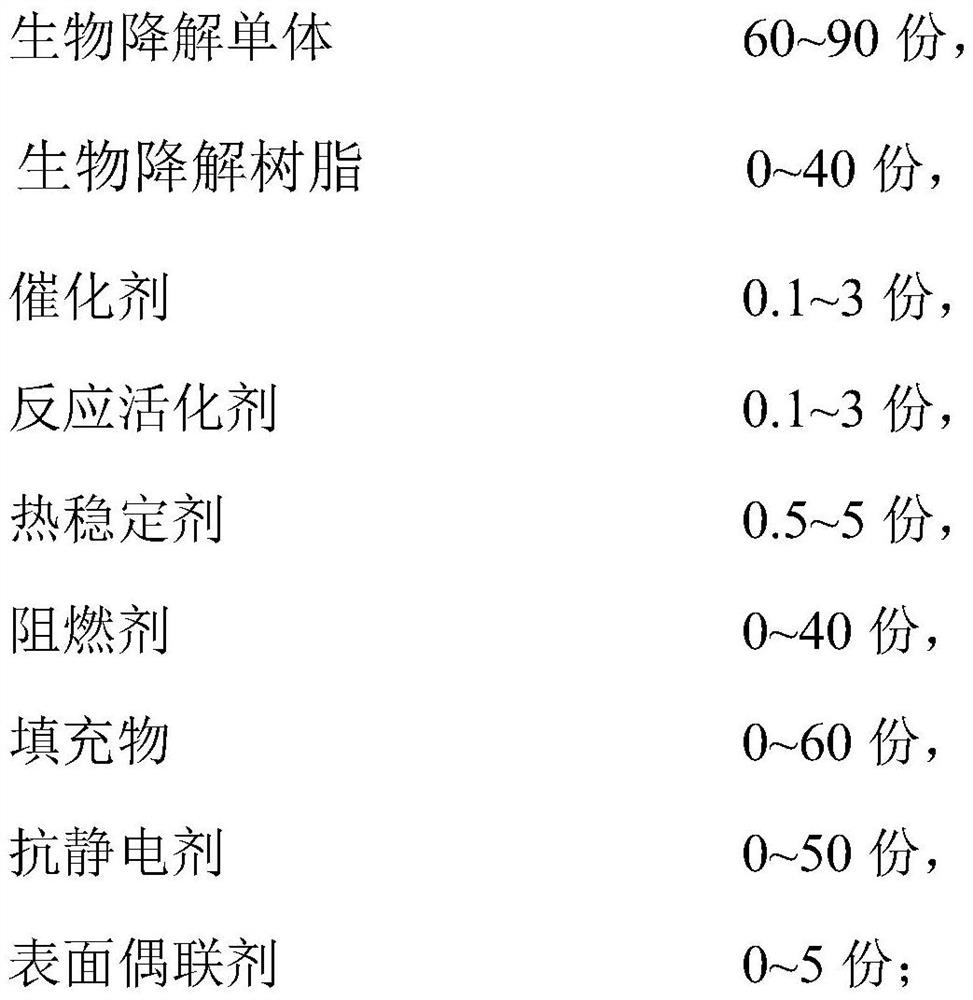

Method used

Image

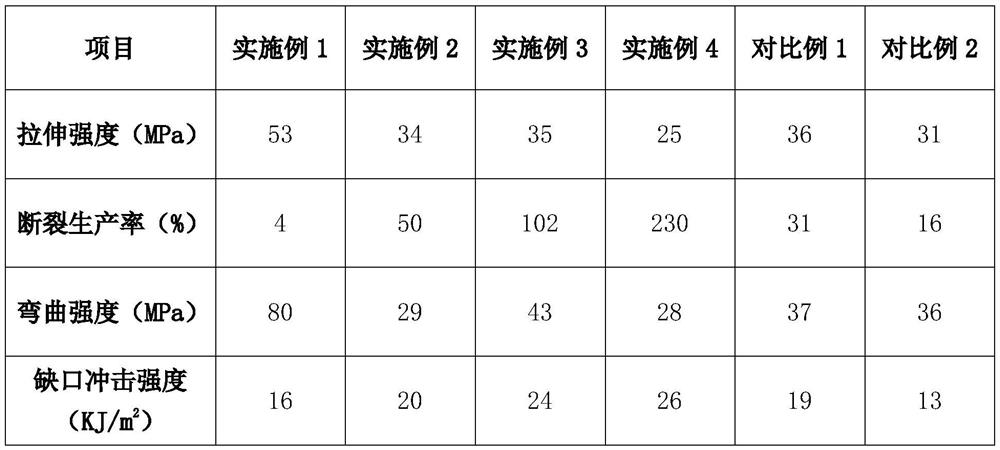

Examples

Embodiment

[0038] This embodiment relates to a fully biodegradable plastic alloy and its preparation.

Embodiment 1

[0039] Implementation 1 Preparation of PLA fully biodegradable alloy

[0040]Add 16.0Kg (80wt%) lactide in a 30L reactor with heating and stirring functions, raise the temperature to 95°C, and connect the vacuum system to maintain a vacuum of 50mbar at the same time, so that the lactide is completely dissolved, and add 120g stearin Zinc acid (0.6wt%) is used as a catalyst, and 120g of maleic anhydride (0.6wt%) is used as a reaction activator. Raise reactor temperature gradually to 110 ℃, add 120g antioxidant 1010 and 120g trialkyl phosphite (0.6wt%) as stabilizer, mix homogeneously, add 1.6Kg magnesium hydroxide (3.2wt%) by side feeding port %) as a flame retardant and the talcum powder filler of 1.6Kg (8.0wt%) processed through the KH560 surface coupling agent of 160g (0.8wt%), further promote the reactor temperature to 130 ℃, mix well, adopt reaction The extruder carries out the polymerization reaction. The length-to-diameter ratio of the extruder is 40. The temperature of ...

Embodiment 2

[0041] Embodiment 2 prepares PLA / PBSA full biodegradable plastic alloy

[0042] In the 30L reactor with heating and stirring reactor, add the lactide of 17Kg (85wt%) and 200g (1wt%) catalyst stannous chloride, setting temperature is 95 ℃, keeps stirring, connects vacuum system simultaneously, Keep a vacuum of 50mbar to dissolve the lactide completely, add 2Kg (10wt%) PBSA, 200g (1wt%) activator dicyclohexylcarbodiimide and 200g (1wt%) heat stabilizer three from the side feed port Alkyl phosphite, keep stirring until the mixture is uniform, raise the temperature to 110°C, dehydrate for 30min, then add the resulting mixture solution into a reactive twin-screw extruder for polymerization, the length-diameter ratio of the extruder is 40. The temperature of heating zones 1 to 6 is set to 100°C, 180°C, 190°C, 180°C, 170°C, 170°C, the melt temperature is 170°C, the head temperature is 160°C, the host speed is 20Hz, and the feeding The speed is 15Hz. Cool and granulate to obtain PLA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com