Borate polymer@hexagonal boron nitride flame-retarding nanoparticles with core-shell structure as well as preparation method and application thereof

A hexagonal boron nitride and nanoparticle technology, applied in the field of organic-inorganic hybrid nanomaterials, can solve the problems of large amount of modified hexagonal boron nitride, uncontrollable modification effect, poor compatibility, etc. Low cost, mild reaction conditions, overcoming the effect of cumbersome reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The preparation of involved multi-arm phenylboronic acid and multi-arm catechol is as follows:

[0057] (1) Dissolve 198mg of 4,4'-diaminodiphenylmethane and 300mg of 4-formylphenylboronic acid in 50mL of methanol, and stir overnight in the dark to obtain a nitrogen-containing two-arm phenylboronic acid solution;

[0058] (2) Dissolve 196mg of six (4-aminophenoxy) cyclotriphosphazene and 207mg of 3,4-dihydroxybenzaldehyde in 50mL of methanol, and stir overnight in the dark to obtain six-arm catechol containing phosphorus nitrogen solution;

[0059] The involved borate polymer@hexagonal boron nitride flame retardant nanoparticles with core-shell structure are prepared as follows:

[0060] (1) Add 160 mg of hexagonal boron nitride to 400 mL of methanol, and ultrasonically disperse it for half an hour to obtain a methanol dispersion of hexagonal boron nitride with a concentration of 0.4 mg / mL;

[0061] (2) Add the hexagonal boron nitride methanol dispersion in step (1) i...

Embodiment 2

[0070] The preparation of involved multi-arm phenylboronic acid and multi-arm catechol is as follows:

[0071] (1) Dissolve 396mg of 4,4'-diaminodiphenylmethane and 600mg of 4-formylphenylboronic acid in 100mL of methanol, and stir overnight in the dark to obtain a nitrogen-containing two-arm phenylboronic acid solution;

[0072] (2) Dissolve 392mg of six (4-aminophenoxy) cyclotriphosphazene and 414mg of 3,4-dihydroxybenzaldehyde in 100mL of methanol, and stir overnight in the dark to obtain six-arm catechol containing phosphorus nitrogen solution;

[0073] The involved borate polymer@hexagonal boron nitride flame retardant nanoparticles with core-shell structure are prepared as follows:

[0074] (1) Add 320 mg of hexagonal boron nitride to 800 mL of methanol, and ultrasonically disperse it evenly for half an hour to obtain a methanol dispersion of hexagonal boron nitride with a concentration of 0.4 mg / mL;

[0075] (2) Add the hexagonal boron nitride methanol dispersion in s...

Embodiment 3

[0084] The preparation of involved multi-arm phenylboronic acid and multi-arm catechol is as follows:

[0085] (1) Dissolve 594mg of 4,4'-diaminodiphenylmethane and 900mg of 4-formylphenylboronic acid in 150mL of methanol, and stir overnight in the dark to obtain a nitrogen-containing two-arm phenylboronic acid solution;

[0086] (2) Dissolve 588mg of six (4-aminophenoxy) cyclotriphosphazene and 621mg of 3,4-dihydroxybenzaldehyde in 150mL of methanol, and stir overnight in the dark to obtain phosphorus-nitrogen-containing six-arm catechol solution;

[0087] The involved borate polymer@hexagonal boron nitride flame retardant nanoparticles with core-shell structure are prepared as follows:

[0088] (1) Add 480 mg of hexagonal boron nitride to 1200 mL of methanol, and ultrasonically disperse it for half an hour to obtain a methanol dispersion of hexagonal boron nitride with a concentration of 0.4 mg / mL;

[0089] (2) Add the hexagonal boron nitride methanol dispersion in step (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

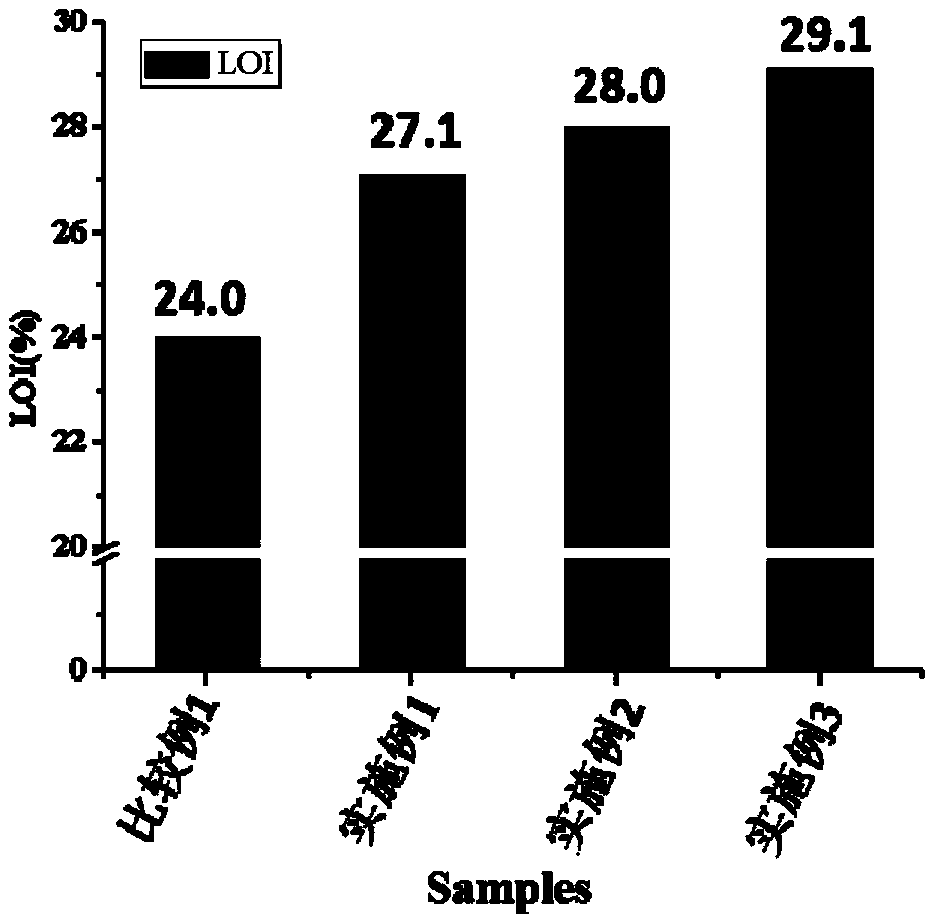

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com