Fe2O3/Sr2FeTaO6-x photocatalyst, preparation method and application thereof

A sr2fetao6-x, photocatalyst technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of high cost, difficult to achieve real bonding, material Problems such as difficulty in increasing body size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

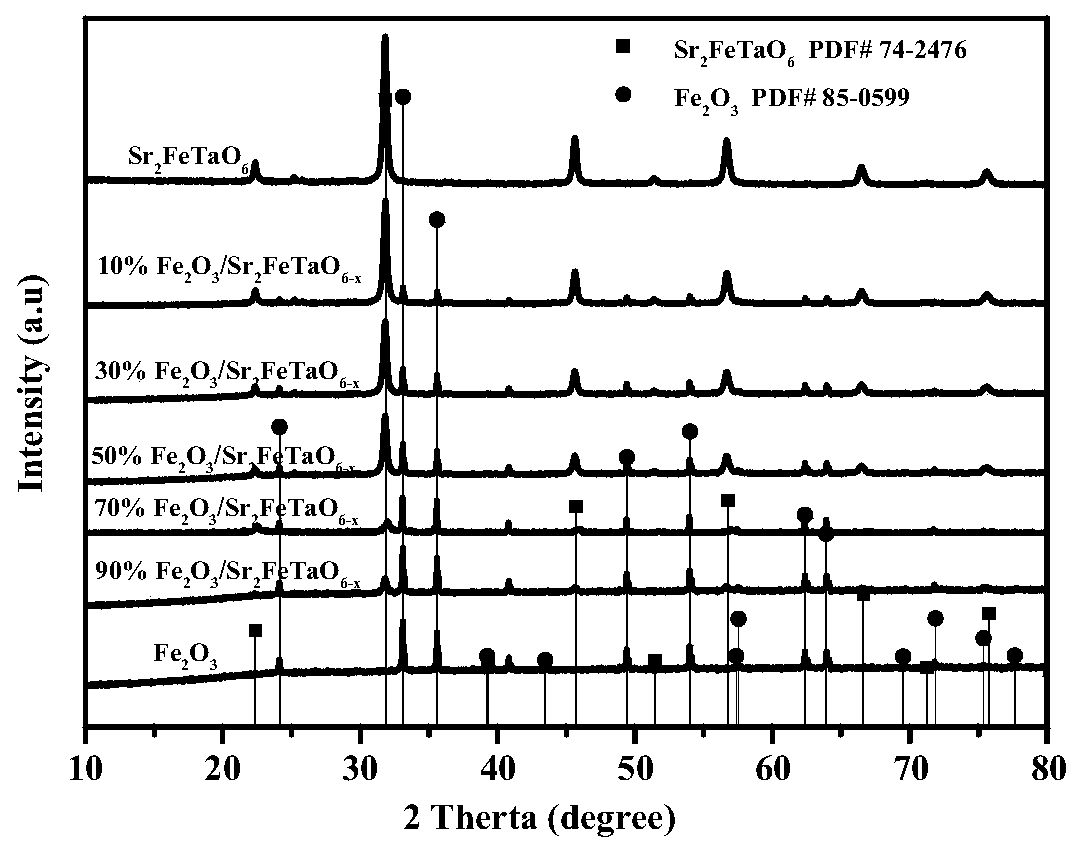

[0048] 30% Fe 2 o 3 / Sr 2 FeTaO 6-x Preparation of Photocatalyst and Evaluation of Nitrogen Oxide Degradation

[0049] (1) Dissolve 7.5ml of oleic acid in 52.5ml of absolute ethanol, then add 300mg of sodium oleate, stir well to make it completely dissolve;

[0050] (2) Add 1.074g of tantalum pentachloride to the above solution, then add 1.059g of iron acetylacetonate and 1.234g of strontium acetate, and stir for about 12 hours to completely dissolve it;

[0051] (3) Add sodium hydroxide solution (8M), stir to dissolve, and the pH of the solution is 12 at this time.

[0052] (4) Add the solution to a hydrothermal kettle for hydrothermal reaction at 200°C, heat the reaction for 12 hours, rinse with absolute ethanol and water, and dry to obtain Sr 2 FeTaO 6 Powder;

[0053] (5) Sr obtained by step (4) 2 FeTaO 6 The powder sample is mixed with calcium hydride powder at a molar ratio of 1:10, ground, and mixed thoroughly. The above sample is moved to a muffle furnace, and...

Embodiment 2

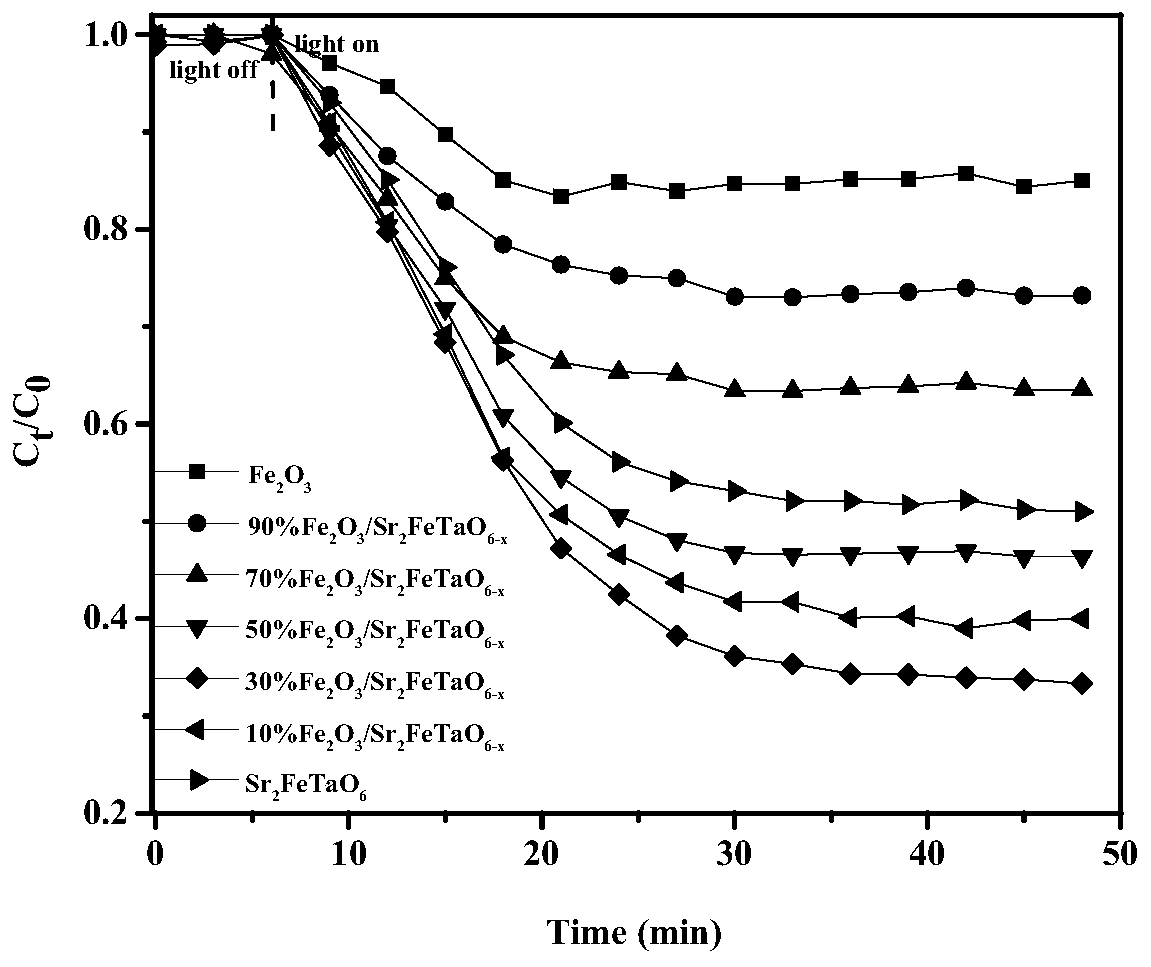

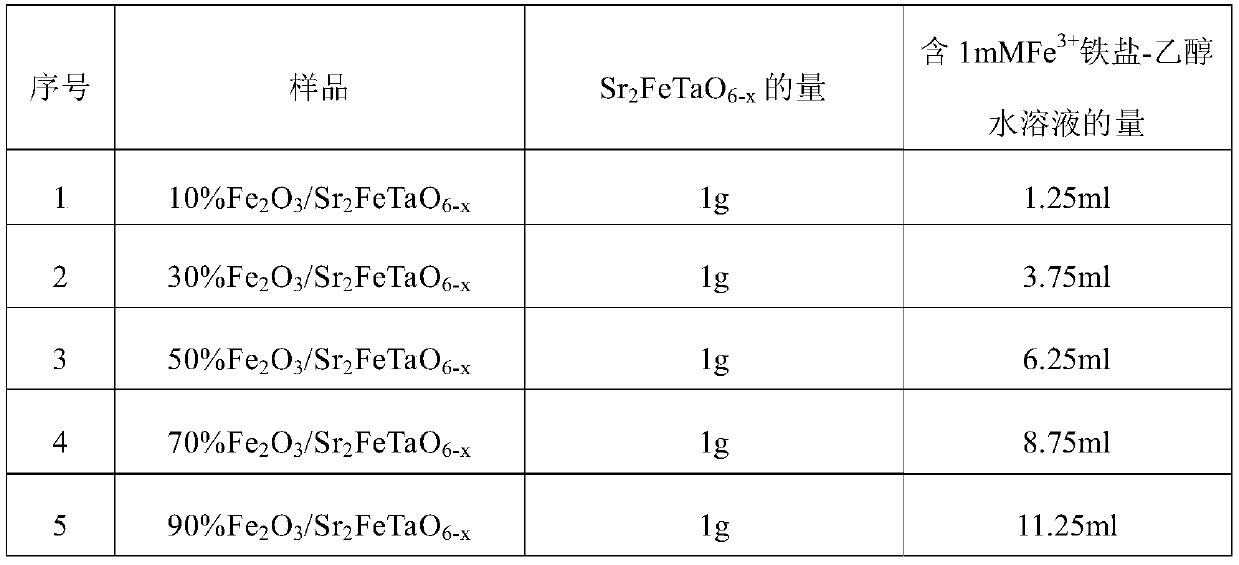

[0064] Using the same method as in Example 1, the difference is: the Sr of 1g 2 FeTaO 6-x The sample powder was added to 1.25mL iron salt-ethanol aqueous solution to finally obtain 10% Fe 2 o 3 / Sr 2 FeTaO 6-x . The conversion rate of NO is around 65%

Embodiment 3

[0066] Using the same method as in Example 1, the difference is: the Sr of 1g 2 FeTaO 6-x The sample powder was added to 6.25mL iron salt-ethanol aqueous solution to finally obtain 50% Fe 2 o 3 / Sr 2 FeTaO 6-x . The conversion rate of NO is around 55-60%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com