A pavement material capable of degrading automobile exhaust and its preparation method

A technology for automobile exhaust and pavement materials, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of limited exhaust gas treatment effect and rapid escape of automobile exhaust gas, so as to ensure adsorption and degradation performance and promote homogenization preparation, pore-rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

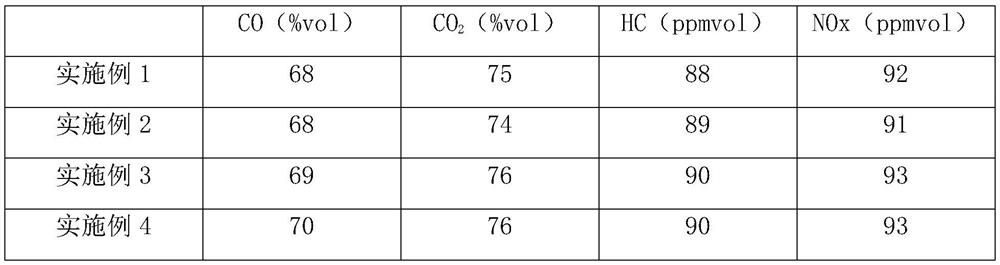

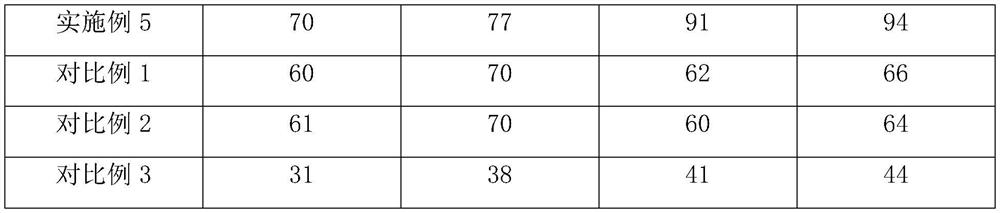

Examples

Embodiment 1

[0034] A preparation method for a pavement material with degradable automobile exhaust gas, the specific steps are as follows:

[0035] (1) After the carbon fiber prefabricated body is mixed with nano-cuprous oxide, it is sintered at a high temperature in vacuum, then melted and mixed with polyurethane resin at high temperature to make a slurry, and spinned to make a fiber material, which is ready for use;

[0036] (2) Under stirring conditions, slowly pour tetrabutyl titanate into the first part of absolute ethanol to obtain a precursor solution; mix aluminum chloride, deionized water, the second part of absolute ethanol and glacial acetic acid to make a suspension ; Slowly drop the suspension into the precursor solution and stir for 15 minutes to obtain a modified titanium dioxide sol;

[0037] (3) The fiber material obtained in step (1) was added to the modified titanium dioxide sol obtained in step (2), stirred slowly for 2 hours, mixed evenly, vacuum negative pressure imp...

Embodiment 2

[0045] A preparation method for a pavement material with degradable automobile exhaust gas, the specific steps are as follows:

[0046] (1) After the carbon fiber prefabricated body is mixed with nano-cuprous oxide, it is sintered at a high temperature in vacuum, then melted and mixed with polyurethane resin at high temperature to make a slurry, and spinned to make a fiber material, which is ready for use;

[0047] (2) Under stirring conditions, slowly pour tetrabutyl titanate into the first part of absolute ethanol to obtain a precursor solution; mix aluminum chloride, deionized water, the second part of absolute ethanol and glacial acetic acid to make a suspension ; Slowly drop the suspension into the precursor solution and stir for 20 minutes to obtain a modified titanium dioxide sol;

[0048] (3) The fiber material obtained in step (1) was added to the modified titanium dioxide sol obtained in step (2), stirred slowly for 3 hours, mixed evenly, impregnated in vacuum negati...

Embodiment 3

[0056] A preparation method for a pavement material with degradable automobile exhaust gas, the specific steps are as follows:

[0057] (1) After the carbon fiber prefabricated body is mixed with nano-cuprous oxide, it is sintered at a high temperature in vacuum, then melted and mixed with polyurethane resin at high temperature to make a slurry, and spinned to make a fiber material, which is ready for use;

[0058] (2) Under stirring conditions, slowly pour tetrabutyl titanate into the first part of absolute ethanol to obtain a precursor solution; mix aluminum chloride, deionized water, the second part of absolute ethanol and glacial acetic acid to make a suspension ; Slowly drop the suspension into the precursor solution and stir for 15 minutes to obtain a modified titanium dioxide sol;

[0059] (3) The fiber material obtained in step (1) was added to the modified titanium dioxide sol obtained in step (2), stirred slowly for 3 hours, mixed evenly, vacuum negative pressure imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com