Dual-modified carbon nitride as well as preparation method and application thereof

A technology of carbon nitride and hydroxylated carbon nitride, which is applied in the field of photocatalytic materials, can solve the problems of poor catalytic effect and poor photocatalytic degradation ability of carbon nitride, so as to promote the separation of local space charges, promote contact, and improve The effect of degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

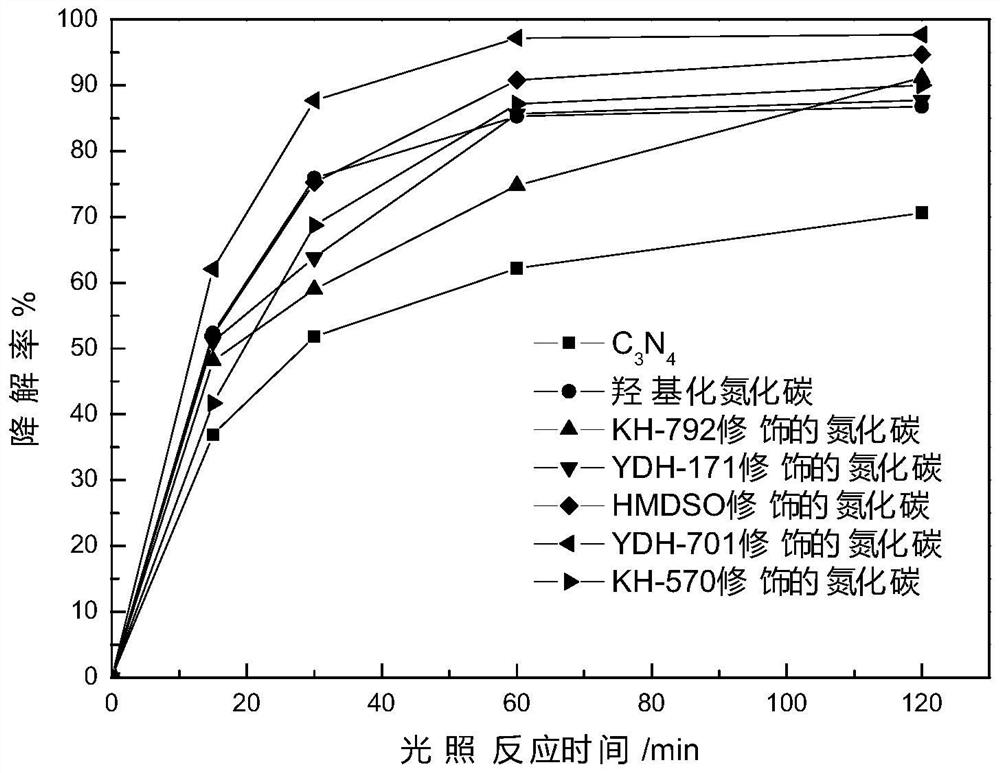

[0049] (1) Preparation of carbon nitride and photocatalytic degradation of carbon nitride for dye wastewater MB, degradation rate of MB.

[0050] Weigh 10g of solid melamine with an electronic balance, put it in a crucible, put it in a muffle furnace, set the program to 2.3°C / min from 20°C to 550°C, and hold at 550°C for 3 hours until the reaction is complete.

[0051] will C 3 N 4 In the process of photocatalytic degradation of dye wastewater MB, for 10 mg / L MB aqueous solution, the degradation rates of MB were 36.9%, 51.8%, 62.2%, and 70.6% for 15 min, 30 min, 60 min, and 120 min of light reaction, respectively.

[0052] (2) Preparation of hydroxylated carbon nitride and test of MB degradation rate.

[0053] Weigh 0.5g of C 3 N 4 Add 50 mL of 20% hydrogen peroxide solution and place it in a heating stirrer and stir with a constant temperature water bath at 25°C for different times. Suction filtration, put in an oven for 24h, scrape off, grind, weigh and bottle.

[0054...

Embodiment 1

[0057] In this example, the KH-792 modified hydroxylated carbon nitride was prepared by the following steps

[0058] Accurately weigh 0.1 g of hydroxylated C 3 N 4 In a three-necked flask, add 50 mL of toluene solvent, ultrasonically disperse for 10 min at room temperature, add 0.1 mL of KH-792, and react at 80 °C for 8 h under stirring and refluxing. After the reaction was completed and the temperature dropped to room temperature, it was filtered, washed twice with toluene and anhydrous ethanol, and dried under vacuum at 100 °C for 12 h to obtain KH-792 modified hydroxylated C 3 N 4 Pale yellow powder.

Embodiment 2

[0060] In this example, YDH-171 modified hydroxylated carbon nitride was prepared by the following steps

[0061] Accurately weigh 0.1 g of hydroxylated C 3 N 4 In a three-necked flask, add 50 mL of toluene solvent, ultrasonically disperse for 10 min at room temperature, add 0.1 mL of YDH-171, and react at 80 °C for 8 h under stirring and refluxing. After the reaction was completed and the temperature dropped to room temperature, it was filtered, washed twice with toluene and anhydrous ethanol, and dried under vacuum at 100 °C for 12 h to obtain YDH-171-modified hydroxylated C 3 N 4 Pale yellow powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com