Preparation method and application of oxygen-sulfur double-doped carbon nitride visible light catalytic material

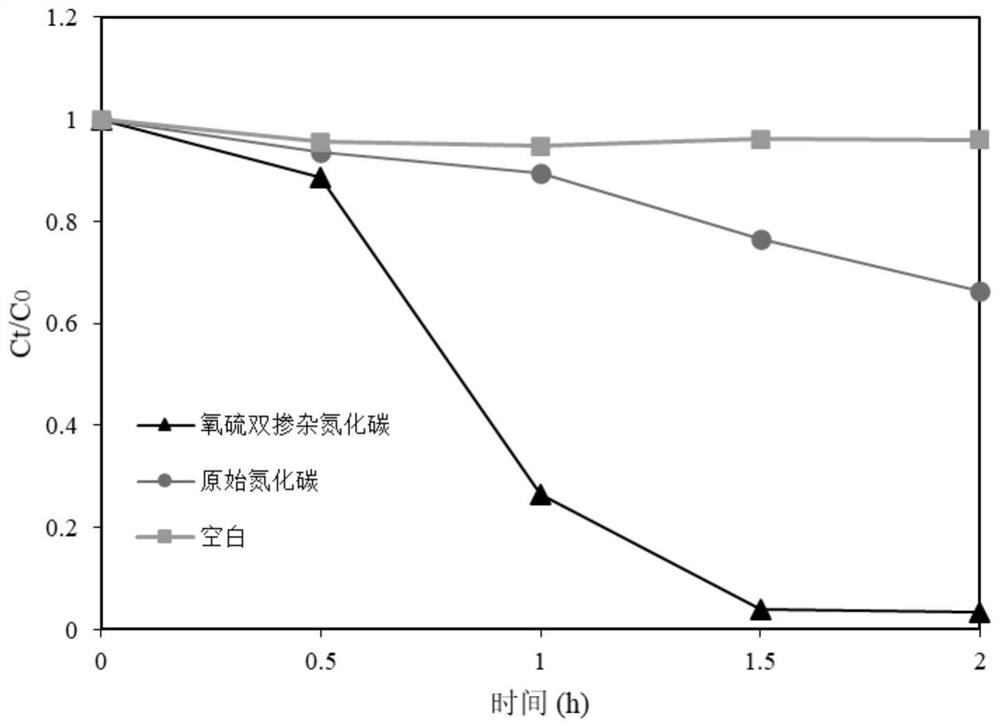

A catalytic material, carbon sulfur nitride technology, applied in the field of water pollution control, can solve the problems of difficult degradation and slow degradation rate of microplastics in water, and achieve the effect of reducing accumulation and increasing degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1- Preparation of Oxygen-Sulphur Double-doped Carbon Nitride Visible Light Catalytic Material

[0037]Pre-mixing method to prepare sulfur-doped carbon nitride material: mix melamine and thiourea at a mass ratio of 1:10, weigh a certain amount of mixture and place it in a crucible, and use a tube furnace to fire sulfur-doped carbon nitride at high temperature Material, the temperature is set to about 550°C, and the firing time is set to 4h. During the firing process, nitrogen gas is continuously blown into the tube, and finally dark yellow lumps are obtained, which are then placed in a mortar and ground into powder to obtain sulfur-doped carbon nitride material;

[0038] (2) Preparation of oxygen-sulfur double-doped carbon nitride material by post-blending method: place the sulfur-doped carbon nitride material in a high-temperature reaction kettle, and add a 30% superfluidic acid with a mass fraction of about 1:100 according to the solid-liquid ratio. The hydrog...

Embodiment 2

[0039] The preparation of embodiment 2-carbon nitride material

[0040] Weigh a certain amount of melamine and place it in a crucible, and use a tube furnace to fire sulfur-doped carbon nitride material at high temperature. The temperature is set at about 550°C, and the firing time is set at 4 hours. During the firing process, nitrogen gas is continuously blown into the tube. , and finally obtain a light yellow lump, which is then placed in a mortar and ground into a powder to obtain a carbon nitride material.

Embodiment 3

[0041] The characterization of embodiment 3-embodiment 1 and embodiment 2 gained materials

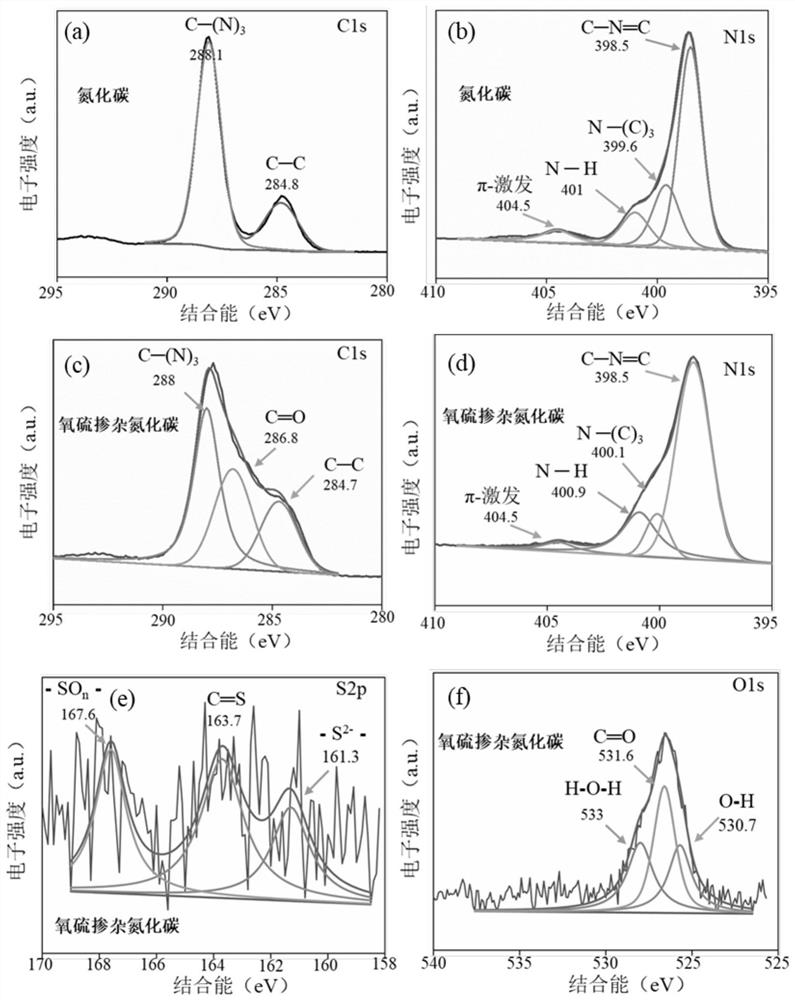

[0042] Using FTIR spectrum and XPS, the obtained carbon nitride and the oxygen-sulfur doped carbon nitride of the present invention were respectively subjected to physical and chemical characterization. The characterization is as follows: by measuring the structure, surface functional groups, and chemical composition of carbon nitride and oxygen-sulfur doped carbon nitride, the changes in physical and chemical properties before and after modification are analyzed. The specific measurement methods are as follows:

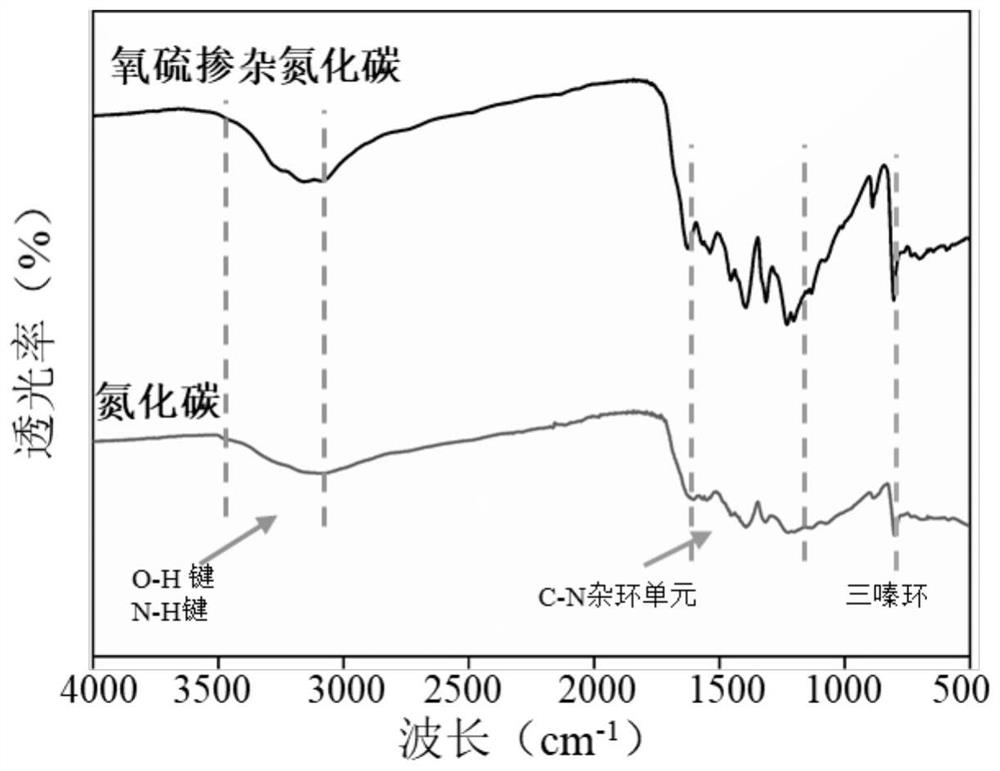

[0043] Measured using a Fourier transform infrared spectrometer. Place the material evenly on the ATR chip with a spatula and start scanning. Instrument parameters: scanning area 4000-500cm -1 , 50 scans, resolution 4cm -1 . For test results, see the attached figure 1 , as shown in the figure, the oxygen-sulfur doped carbon nitride of the present invention is obviously d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com