Environment-friendly composite mattress containing bamboo fibers and preparation method of environment-friendly composite mattress

A bamboo fiber and environment-friendly technology, applied in the field of environment-friendly composite mattresses and their preparation, can solve the problems of poor air permeability of mattresses, affect people's sleep, and be detrimental to physical health, and achieve rich inner pores, inhibition of microbial growth, The effect of maintaining good health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

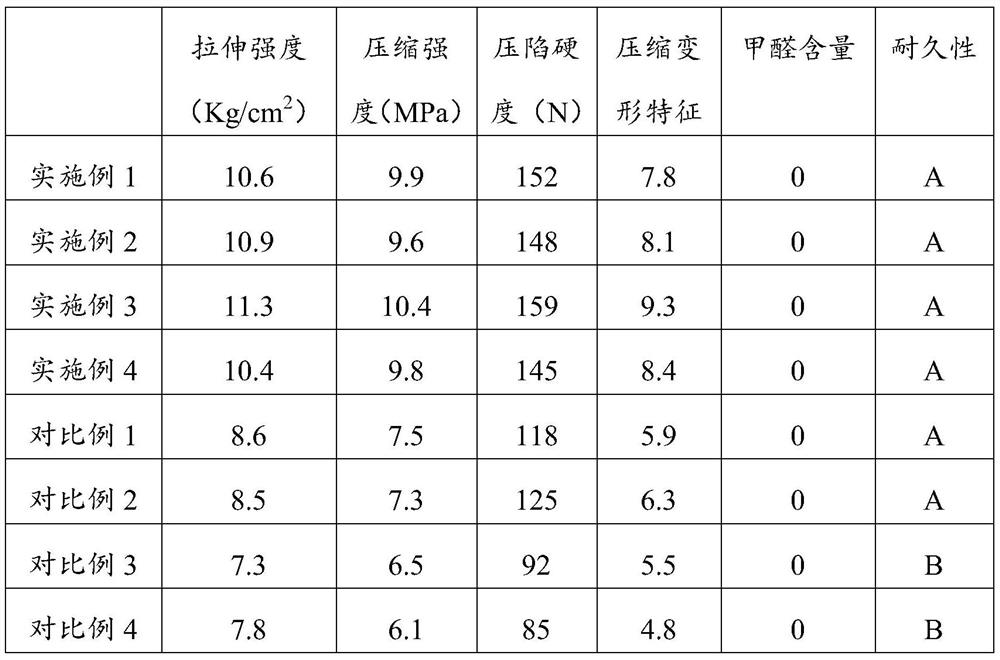

Examples

Embodiment 1

[0031] Embodiment 1 A kind of environment-friendly composite mattress containing bamboo fiber

[0032] An environment-friendly composite mattress containing bamboo fiber is prepared from the following raw material components in parts by weight: 80 parts of low-density polyethylene, 20 parts of modified bamboo fiber, 12 parts of attapulgite, 3 parts of foaming agent, 0.8 part of joint agent, 0.8 part of foam shrinkage aid, 0.4 part of foam stabilizer, 3 parts of surfactant and 300 parts of modified liquid, and its preparation method specifically includes the following steps:

[0033] (1) pulverize and grind the attapulgite, and pass through a 100-mesh sieve to obtain the attapulgite particles, and weigh each component according to the weight ratio of the raw materials;

[0034] (2) The above-mentioned attapulgite particles, low-density polyethylene, foaming agent, coupling agent, foam shrinkage aid, foam stabilizer and surfactant are uniformly mixed, and added to a two-roller r...

Embodiment 2

[0040] Embodiment 2 A kind of environment-friendly composite mattress containing bamboo fiber

[0041] An environment-friendly composite mattress containing bamboo fiber is prepared from the following raw material components in parts by weight: 70 parts of low-density polyethylene, 10 parts of modified bamboo fiber, 18 parts of attapulgite, 6 parts of foaming agent, 0.5 part of joint agent, 0.4 part of foam shrinkage aid, 0.1 part of foam stabilizer, 5 parts of surfactant and 150 parts of modified liquid. The preparation method is the same as in Example 1, and specific reference is made to Example 1.

[0042] The preparation method of the above-mentioned modified bamboo fiber is as follows: 1 kg of bamboo fiber through removal of impurities is added to a NaOH solution with a mass concentration of 2%, soaked for 0.5 h, then added 36 g of alkyl phosphorus carboxylate, and heated to 70 °C while stirring. React at -80°C for 1-2 hours, filter, wash with deionized water three times,...

Embodiment 3

[0045] Embodiment 3 A kind of environment-friendly composite mattress containing bamboo fiber

[0046] An environment-friendly composite mattress containing bamboo fiber is prepared from the following raw material components in parts by weight: 75 parts of low-density polyethylene, 15 parts of modified bamboo fiber, 15.4 parts of attapulgite, 4 parts of foaming agent, 0.7 part of joint agent, 0.7 part of foam shrinkage aid, 0.2 part of foam stabilizer, 4 parts of surfactant and 220 parts of modified liquid. The preparation method is the same as in Example 1, and specific reference is made to Example 1.

[0047] The preparation method of the above-mentioned modified bamboo fiber is as follows: 1 kg of bamboo fiber through removal of impurities is added to a NaOH solution with a mass concentration of 2%, soaked for 0.5 h, then added 30 g of alkyl phosphorus carboxylate, and heated to 70 °C while stirring. React at -80°C for 1-2 hours, filter, wash with deionized water three time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com