Modified carbon nano tube/thermosetting resin composite material and preparation method thereof

A resin composite material and carbon nanotube technology, which is applied in the field of modified carbon nanotube/thermosetting resin composite materials and their preparation, can solve the problem of low-cost manufacturing of high-performance composite materials with unfavorable filling amount, increasing industrial difficulty of composite materials, and disadvantages. Material dielectric constant and other issues, to achieve the effect of low-cost manufacturing, low dielectric loss, and reduced dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Synthesis of lithium-titanium-doped nickel oxide

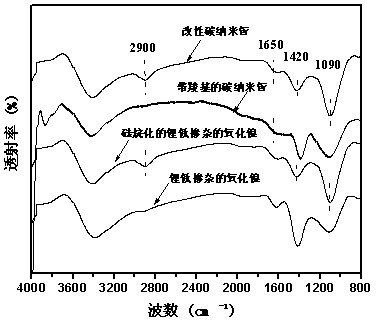

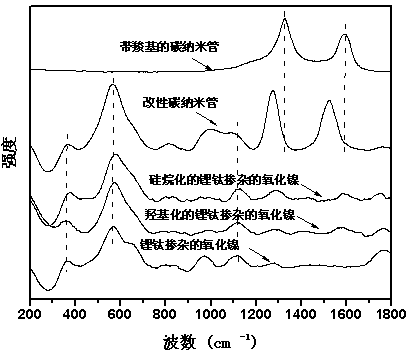

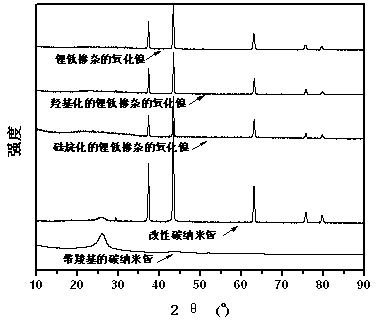

[0034]Dissolve 50g of citric acid in 80mL of ethylene glycol, add 5.12g of lithium nitrate, 49.5g of nickel nitrate and 1.7g of butyl titanate in sequence at 100°C, keep warm at 150°C for 8 hours, and then heat The solution was kept at 350°C for 2 hours to obtain a gray powder; the gray powder was ground to pass through a 140-mesh sieve; calcined at 800°C for 1 hour to obtain black lithium-titanium-doped nickel oxide, its infrared spectrum, Raman spectrum, The X-ray diffraction pattern is as figure 1 , 2 and 3.

[0035] 2. Preparation of silanized lithium-titanium-doped nickel oxide

[0036] Disperse 10 g of lithium-titanium-doped nickel oxide that can pass through a 140-mesh sieve after grinding in 50 mL of 35% hydrogen peroxide solution, and react at a temperature of 90 °C for 5 h; after the reaction, deionized Washed with water, filtered with suction, and dried under vacuum at 50°C for 24 hours to obtain hydro...

Embodiment 2

[0050] 1. Preparation of modified carbon nanotubes

[0051] 300mg of the carboxyl-containing carbon nanotubes prepared in Example 1 were dispersed in 120mL of N,N-dimethylformamide, and 600mg of the silanized lithium-titanium-doped nickel oxide prepared in Example 1 was added, at a temperature of 70°C Under the condition of reaction 24h. Washing with absolute ethanol, suction filtration, and vacuum drying at 50° C. for 24 hours to obtain modified carbon nanotubes, wherein the amount of lithium-titanium-doped nickel oxide grafted is twice the mass of carbon nanotubes. Its 30,000 times magnified scanning electron microscope image and conductivity curve Figure 6 , 7 shown.

[0052] 2. Preparation of modified carbon nanotubes / epoxy resin composites

[0053] Add 1.5g of the modified carbon nanotubes prepared in this example and 100g of epoxy resin (grade E-51) into the flask, stir at 60°C and ultrasonically for 1h, vacuum defoam for 30min, add 4g of 2-ethyl -4-Methylimidazole...

Embodiment 3

[0055] 1. Preparation of modified carbon nanotubes

[0056] 300 mg of carbon nanotubes with carboxyl groups prepared in Example 1 were dispersed in 120 mL of N,N-dimethylformamide, and 300 mg of silanized lithium-titanium-doped nickel oxide prepared in Example 1 was added, at a temperature of 70° C. Under the condition of reaction 24h. Washing with absolute ethanol, suction filtration, and vacuum drying at 50° C. for 24 hours to obtain modified carbon nanotubes, wherein the amount of lithium-titanium-doped nickel oxide grafted is 1 times the mass of carbon nanotubes. Its 30,000 times magnified scanning electron microscope image and conductivity curve Figure 6 , 7 shown.

[0057] 2. Preparation of modified carbon nanotubes / epoxy resin composites

[0058] Add 1.0 g of the modified carbon nanotubes prepared in this example and 100 g of bisphenol A epoxy resin (brand E-51) into the flask, stir at 60°C and ultrasonically for 1 hour, vacuum degassing for 30 minutes, and add 4 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com