Coating and self-spraying paint

A technology of coating and parts by weight, applied in the field of coating and self-spraying paint, can solve the problems of high labor intensity, high cost of raw materials, inapplicability, etc., achieve low labor intensity and cost, improve chemical resistance, and improve construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

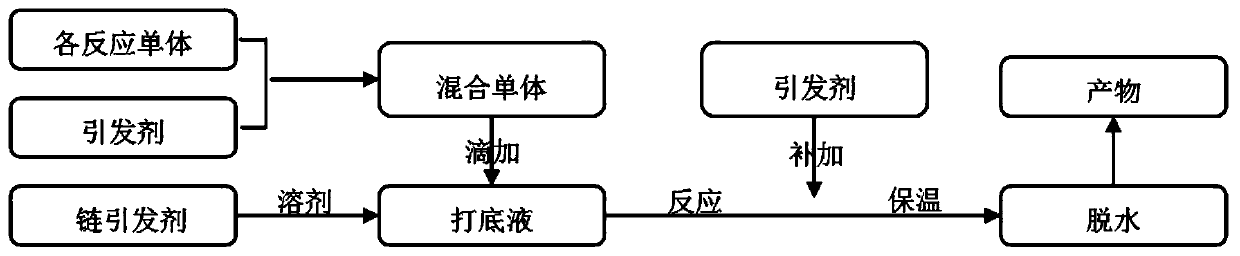

Method used

Image

Examples

Embodiment 1~ Embodiment 3

[0076] The preparation method of embodiment 1~embodiment 3 is:

[0077] S1. Put the amount of xylene in the formula shown in Table 1 into a clean container, add the dispersant accurately, and disperse with a disperser at 800-1000 rpm for 10-15 minutes after soaking.

[0078] S2. Adjust the speed of the disperser to 300-400 rpm. In the dispersed state, add polysulfide thermoplastic acrylic resin. After adding the resin, adjust the speed of the disperser to 800-1000 rpm and continue to disperse for 20-25 minutes. minute.

[0079] S3, then continue to adjust the rotational speed of the disperser to 300-400 rpm, and in the dispersed state, slowly add the pigment, anti-rust filler, and fumed silica in sequence. After all the powder has entered the liquid phase, wash the container wall with a small amount of xylene. Then adjust the rotating speed of the disperser to 1000-1500 rpm, and continue to disperse for 25-30 minutes to obtain a mixture.

[0080] S4, grind the above mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com