A kind of antistatic ABS resin composition with improved chemical resistance and preparation method thereof

An ABS resin and composition technology, applied in the field of polymer material processing, can solve the problems of low chemical resistance and weak electrical conductivity, and achieve the effects of low cost, improved chemical resistance, and comfortable touch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

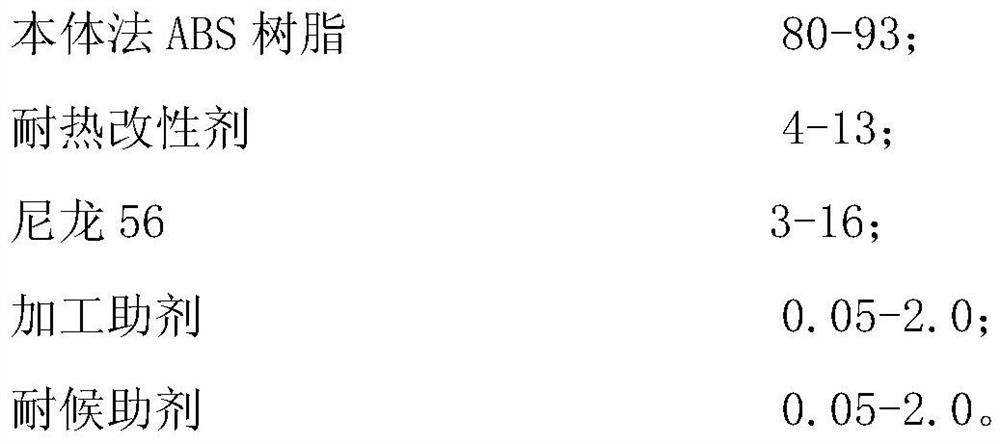

Method used

Image

Examples

Embodiment 1

[0037] An antistatic ABS resin composition with improved chemical resistance, prepared from the following components and raw materials in parts by weight: 85 parts of bulk ABS resin, 6 parts of heat-resistant modifier, 9 parts of nylon 56, and processing aids 0.1 part, 0.1 part of weather resistance additive, appropriate amount of color matching pigment.

[0038] Among the above raw materials, the weight average molecular weight of bulk ABS resin is 15,000g / mol; the content of maleic anhydride in heat-resistant modifier is 6%; the relative viscosity of nylon 56 is 2.2, and the content of terminal amino group is 50%.

[0039] (1) premixing the above-mentioned raw materials in a high-speed mixer;

[0040] (2) Pass the premixed material obtained in (1) through a twin-screw extruder, melt and extrude it at an extrusion temperature of 220-250° C. and a screw speed of 200-500 rpm, and cool and granulate to obtain Antistatic ABS resin composition with improved chemical resistance. ...

Embodiment 2

[0042] An antistatic ABS resin composition with improved chemical resistance, which is prepared by using the following components and raw materials in parts by weight: 82 parts of bulk method ABS resin, 6 parts of heat-resistant modifier, 12 parts of nylon 56, and processing aids 0.1 part, 0.1 part of weather resistance additive, appropriate amount of color matching pigment.

[0043] Among the above raw materials, the weight average molecular weight of bulk ABS resin is 15,000g / mol; the content of maleic anhydride in heat-resistant modifier is 6%; the relative viscosity of nylon 56 is 2.2, and the content of terminal amino group is 50%.

[0044] (1) premixing the above-mentioned raw materials in a high-speed mixer;

[0045] (2) Pass the premixed material obtained in (1) through a twin-screw extruder, melt and extrude it at an extrusion temperature of 220-250° C. and a screw speed of 200-500 rpm, and cool and granulate to obtain Antistatic ABS resin composition with improved c...

Embodiment 3

[0047] An antistatic ABS resin composition with improved chemical resistance, prepared by using the following components and raw materials in parts by weight: 90 parts of bulk ABS resin, 6 parts of heat-resistant modifier, 4 parts of nylon 56, and processing aids 0.1 part, 0.1 part of weather resistance additive, appropriate amount of color matching pigment.

[0048] Among the above raw materials, the weight average molecular weight of bulk ABS resin is 15,000g / mol; the content of maleic anhydride in heat-resistant modifier is 6%; the relative viscosity of nylon 56 is 2.2, and the content of terminal amino group is 50%.

[0049] (1) premixing the above-mentioned raw materials in a high-speed mixer;

[0050] (2) Pass the premixed material obtained in (1) through a twin-screw extruder, melt and extrude it at an extrusion temperature of 220-250° C. and a screw speed of 200-500 rpm, and cool and granulate to obtain Antistatic ABS resin composition with improved chemical resistance....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com