Raw lacquer atomization method

A technology of raw lacquer and atomization process, which is applied in the field of raw lacquer application, can solve the problems of unable to lacquer atomized state, etc., and achieve the effect of being beneficial to environmental protection and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

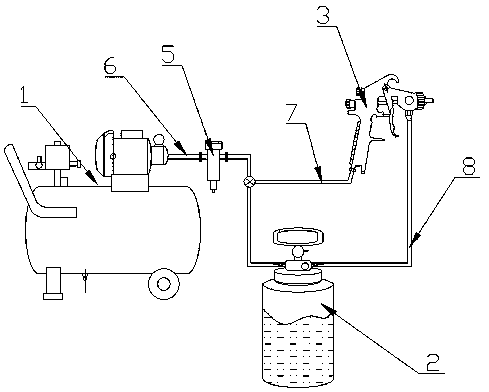

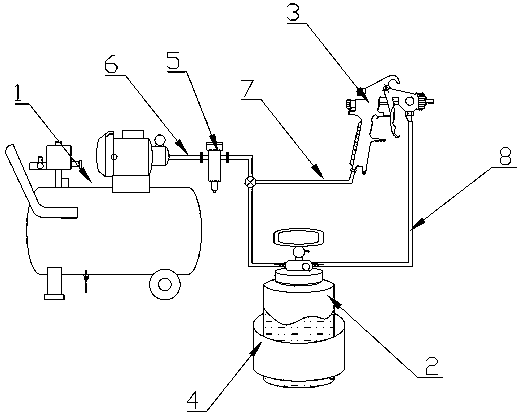

[0023] Embodiment 1: as figure 1 As shown, the raw lacquer atomization method uses a pneumatic paint spraying device for atomization; a spray gun 3 with a nozzle size of 0.4mm to 2.5mm is used; the pressure during the atomization process is 5Pa to 13Pa higher than the ambient air pressure; raw lacquer itself is a high Molecular compound is also a typical non-Newtonian fluid, its viscosity will change under the action of shear force; raw lacquer belongs to the expansion fluid in non-Newtonian fluid, and its viscosity value increases with the shear force and increase; when a small shear force is applied, the raw lacquer cannot flow, and only when the added shear force exceeds a certain value can it start to flow; if the raw lacquer is sprayed with a high-pressure pump, the viscosity of the raw lacquer will increase. As a result, it is difficult to atomize, and even blockage of pipes and nozzles may occur; and if no pressure is applied to the raw paint, it cannot be sprayed out t...

Embodiment 2

[0027] Embodiment 2: as figure 1 As shown, the raw lacquer atomization method uses a pneumatic paint spraying device for atomization; a spray gun 3 with a nozzle size of 0.4mm is used; an air pressure of 5Pa is added during the atomization process; if the pressure applied during the atomization process is less than 5Pa, the raw lacquer cannot be made If the flow is generated, if the nozzle size of the spray gun 3 is lower than 0.4 mm, the raw lacquer cannot be sprayed out.

[0028] The pneumatic paint spraying device includes an air compressor 1, a pressure tank 2 and a spray gun 3; the air compressor 1 is connected to the pressure tank 2 through the first air pipe 6; the spray gun 3 is connected to the pressure tank 2 through the feed pipe 8 The discharge port is connected; the spray gun 3 is connected with the pressure tank 2 through the second gas delivery pipe 7.

[0029] The air compressor 1 is an air compressor. Its principle is to provide air source power. It is the co...

Embodiment 3

[0030] Embodiment 3: as figure 1 As shown, the raw lacquer atomization method uses a pneumatic paint spraying device for atomization; a spray gun 3 with a nozzle size of 2.5mm is used; an air pressure of 10Pa is added during the atomization process; during the atomization process, if the nozzle size of the spray gun 3 used is greater than 2.5mm , even if it is sprayed from the spray gun 3, the raw lacquer cannot be atomized; if the applied pressure is higher than 13Pa, the viscosity of the raw lacquer will increase, which will affect the atomization effect and even fail to be sprayed;

[0031] The pneumatic paint spraying device includes an air compressor 1, a pressure tank 2 and a spray gun 3; the air compressor 1 is connected to the pressure tank 2 through the first air pipe 6; the spray gun 3 is connected to the pressure tank 2 through the feed pipe 8 The discharge port is connected; the spray gun 3 is connected with the pressure tank 2 through the second air pipe 7;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com